Cobalt-ion-doped iron-nickel magnetic microsphere and application thereof

A magnetic microsphere, cobalt ion technology, applied in ion exchange, ion exchange regeneration, ion exchange treatment device and other directions, can solve the problems of high price of agarose gel, large production cost, low production cost, etc., and achieve application effect Fast and efficient, easy large-scale industrial production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

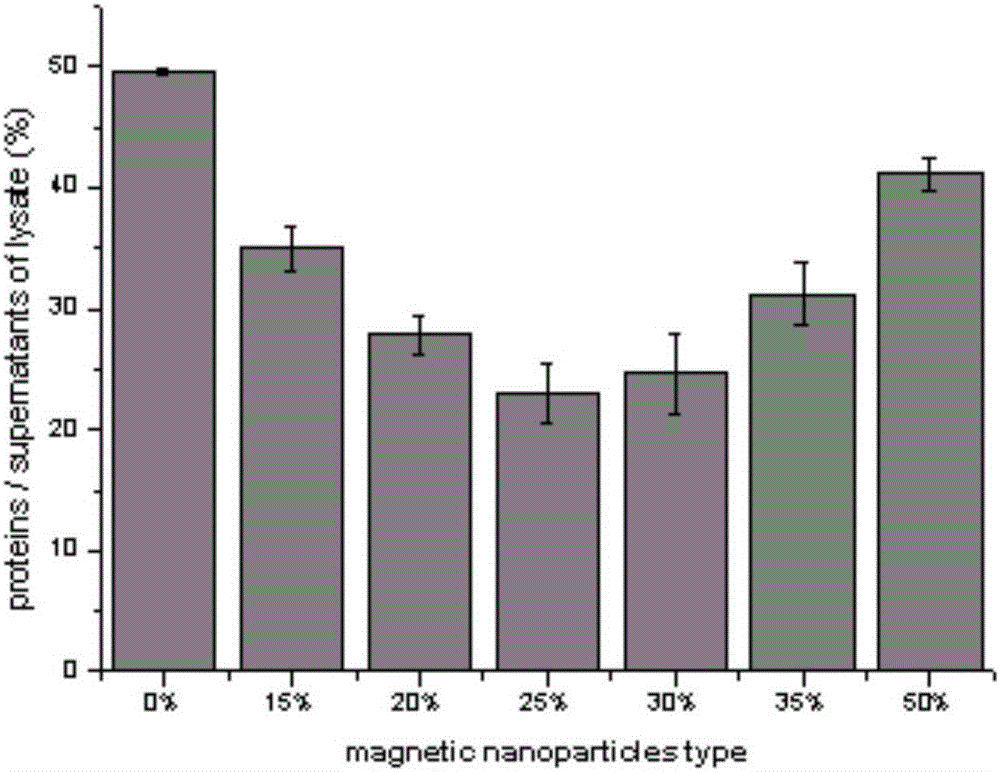

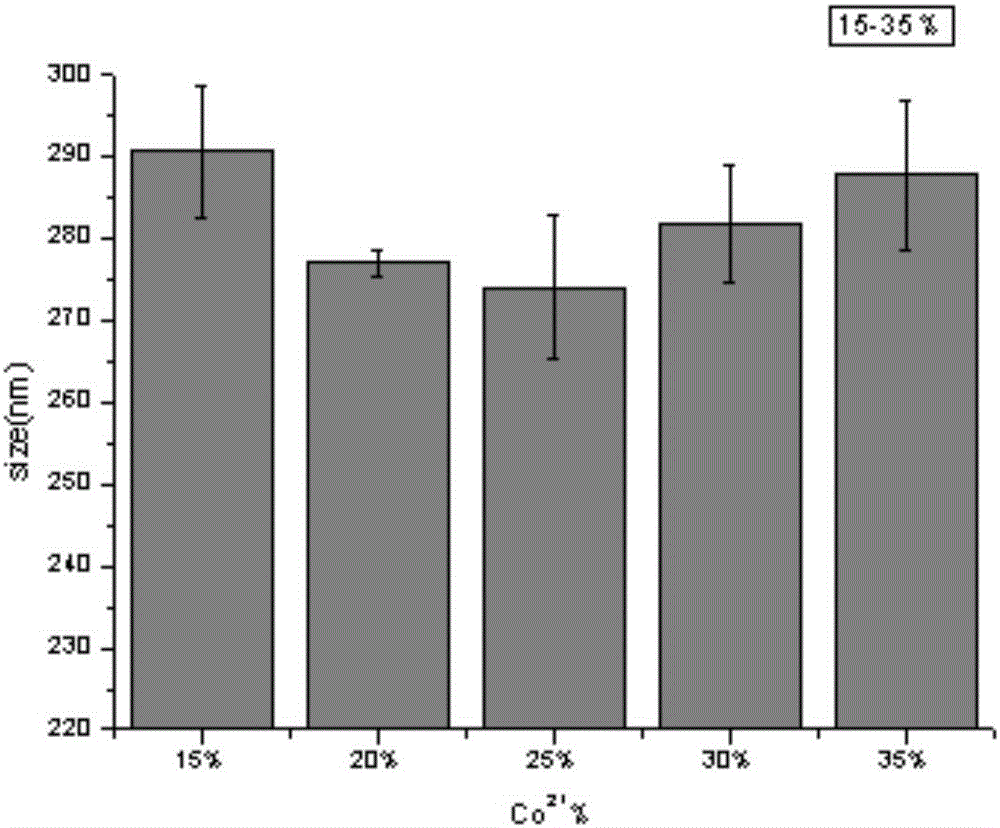

Embodiment 1

[0035] Mix cobalt nitrate and nickel sulfate at a molar ratio of 1:4 (recorded as 20%, indicating that cobalt ions account for 20% of the total moles of cobalt ions and nickel ions), and then mix with iron ions, fully grind and mix for doping Preparation of FeNi magnetic spheres with cobalt ions. The preparation of magnetic balls is based on the principle of thermal decomposition method, and the preparation is completed by a one-pot method. The mixed metal ion salt is added to the ethylene glycol solution at 200 °C under the protection of nitrogen (the oxygen has been fully deoxidized, and sodium acetate and ethanolamine are added to stir. Uniform), keep stirring and reacting for 6h under the protection of nitrogen, then cool to room temperature under the protection of nitrogen and stop the reaction; the synthetic product is washed 5 times with deionized water and 5 times with ethanol solution to obtain 20% cobalt ion-doped Iron nickel magnetic ball.

Embodiment 2

[0037] Mix cobalt nitrate and nickel sulfate according to the molar ratio of ions at 1:3 (recorded as 25%, indicating that cobalt ions account for 25% of the total moles of cobalt ions and nickel ions), and then mix with iron ions, grind and mix thoroughly for use in Preparation of iron-nickel magnetic balls doped with cobalt ions. The preparation of magnetic balls is based on the principle of thermal decomposition method, and the preparation is completed by a one-pot method. The mixed metal ion salt is added to the ethylene glycol solution at 200 °C under the protection of nitrogen (the oxygen has been fully deoxidized, and sodium acetate and ethanolamine are added to stir. homogeneous), keep stirring and reacting for 6h under the protection of nitrogen, then cool to room temperature under the protection of nitrogen and stop the reaction; the synthetic product is washed 7 times with deionized water and 15 times with ethanol solution to obtain 25% doped cobalt ion Iron nickel ...

Embodiment 3

[0039] Mix cobalt nitrate and nickel sulfate according to the molar ratio of ions at 3:7 (recorded as 30%, indicating that cobalt ions account for 30% of the total molar number of cobalt ions and nickel ions), and then mix with iron ions, fully grind and mix for use Preparation of iron-nickel magnetic balls doped with cobalt ions. The preparation of magnetic balls is based on the principle of thermal decomposition method, and the preparation is completed by a one-pot method. The mixed metal ion salt is added to the ethylene glycol solution at 200 °C under the protection of nitrogen (the oxygen has been fully deoxidized, and sodium acetate and ethanolamine are added to stir. uniform), keep stirring and reacting for 6h under the protection of nitrogen, then cool to room temperature under the protection of nitrogen and stop the reaction; the synthesized product is washed 6 times with deionized water and 10 times with ethanol solution to obtain 30% cobalt ion-doped Iron nickel mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com