A kind of copper-containing zincizing agent and method for zincizing metal material

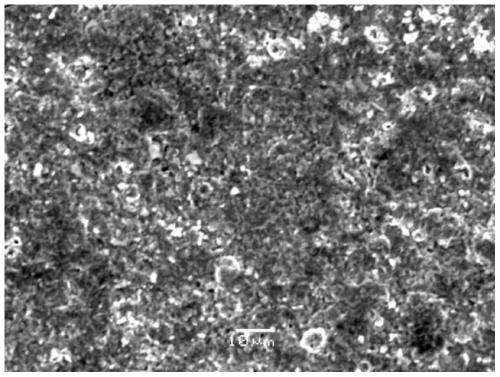

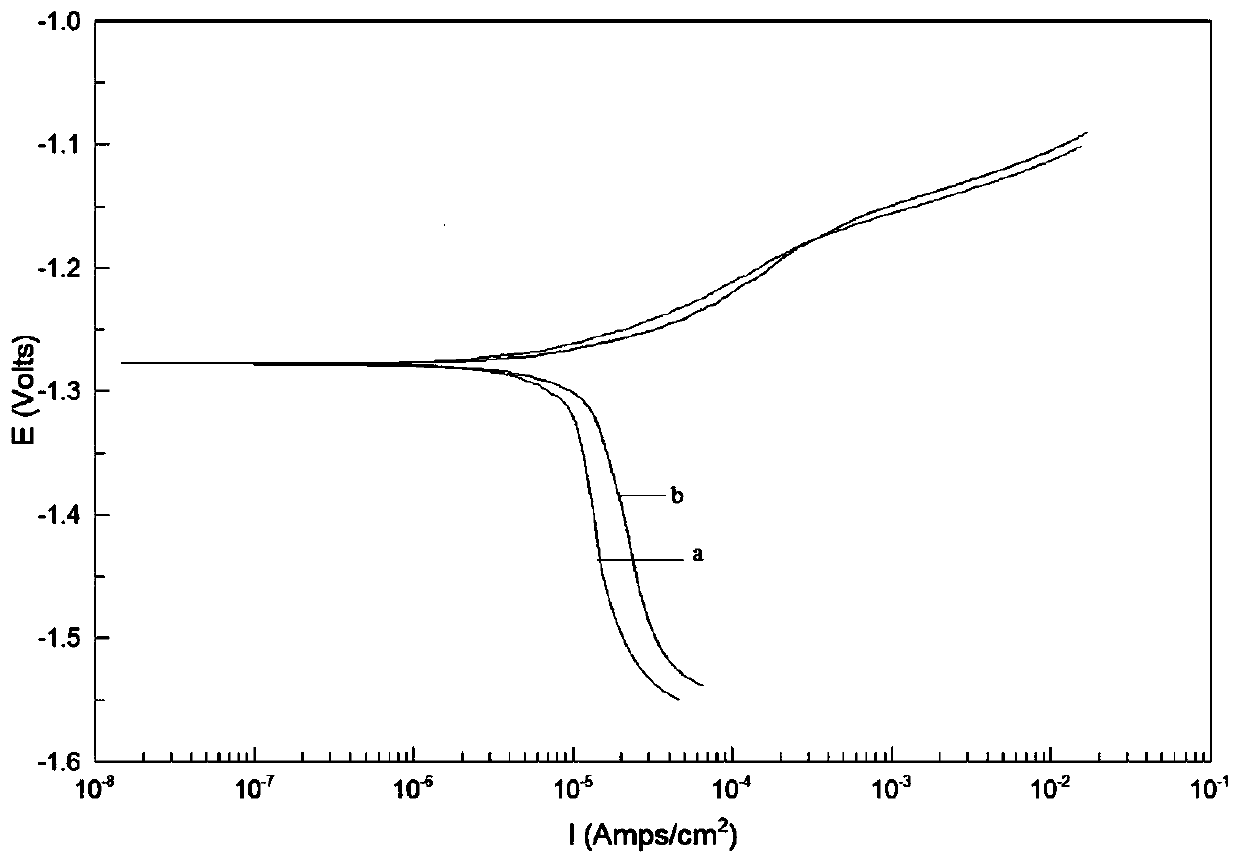

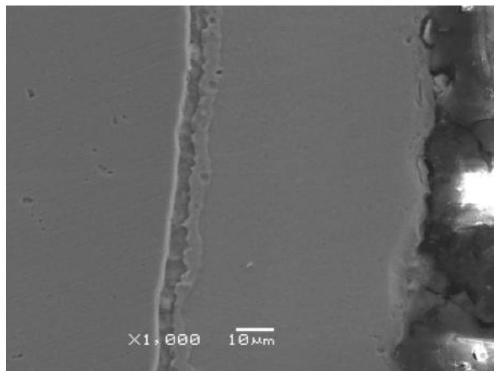

A technology of zinc infiltration and zinc powder, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of corrosion resistance, poor surface compactness, increased thickness of infiltration layer, etc., to improve the surface hardness , the effect of dense layer, self-corrosion potential and corrosion current density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1. Weigh 72% of 200 mesh pure zinc powder, 2% ammonium chloride, 3% lanthanum nitrate, 21.5% aluminum oxide, 1.5% pure copper powder according to mass percentages, and the sum of the above component mass percentages is 100 %;

[0037] Step 2: Mix the materials in Step 1 uniformly, and use a horizontal planetary ball mill to ball mill for 1 hour to obtain a copper-containing sherardizer.

[0038] Step 3. Use wire cutting to obtain a sample with a size of 10*10*3mm, and grind it on a pre-grinding machine with sandpaper with a particle size of 280#, 400#, and 600# until it is bright.

[0039] Step 4. Pre-treat the sample from step 3. Namely alkaline washing-washing-acid washing-washing-drying for later use.

[0040] Step 5. Put the copper-containing zinc infiltrating agent obtained in step 2 together with the sample into a sealed crucible, place it in a tubular resistance furnace, heat up to 455°C with the furnace and keep it warm for 3 hours, and then cool to room temperatu...

Embodiment 2

[0047] Step 1. Weigh 72% of 200 mesh pure zinc powder, 2% ammonium chloride, 3% lanthanum nitrate, 21% aluminum oxide, 2% pure copper powder according to mass percentages, and the sum of the above component mass percentages is 100 %;

[0048] Step 2: Mix the materials in Step 1 uniformly, and use a horizontal planetary ball mill to ball mill for 1 hour to obtain a copper-containing sherardizer.

[0049] Step 3. Use wire cutting to obtain a sample with a size of 10*10*3mm, and grind it on a pre-grinding machine with sandpaper with a particle size of 280#, 400#, and 600# until it is bright.

[0050] Step 4. Pre-treat the sample from step 3. Namely alkaline washing-washing-acid washing-washing-drying for later use.

[0051] Step 5. Put the copper-containing zinc infiltrating agent obtained in step 2 together with the sample into a sealed crucible, place it in a tubular resistance furnace, heat up to 445°C with the furnace and keep it for 3 hours, then cool to room temperature in air to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com