A kind of bioporous carbon-based lithium-sulfur battery cathode material and preparation method thereof

A technology of positive electrode material and porous carbon, which is applied in the field of biological porous carbon-based lithium-sulfur battery positive electrode materials and its preparation, can solve the problems of destroying the structural stability of positive electrode materials, affecting the specific capacity and stability of batteries, and reducing the cycle stability of batteries. , to achieve excellent electrochemical performance, increase binding energy, and increase the effect of micropore content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

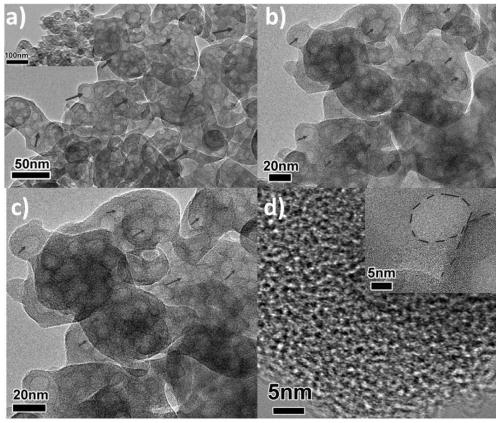

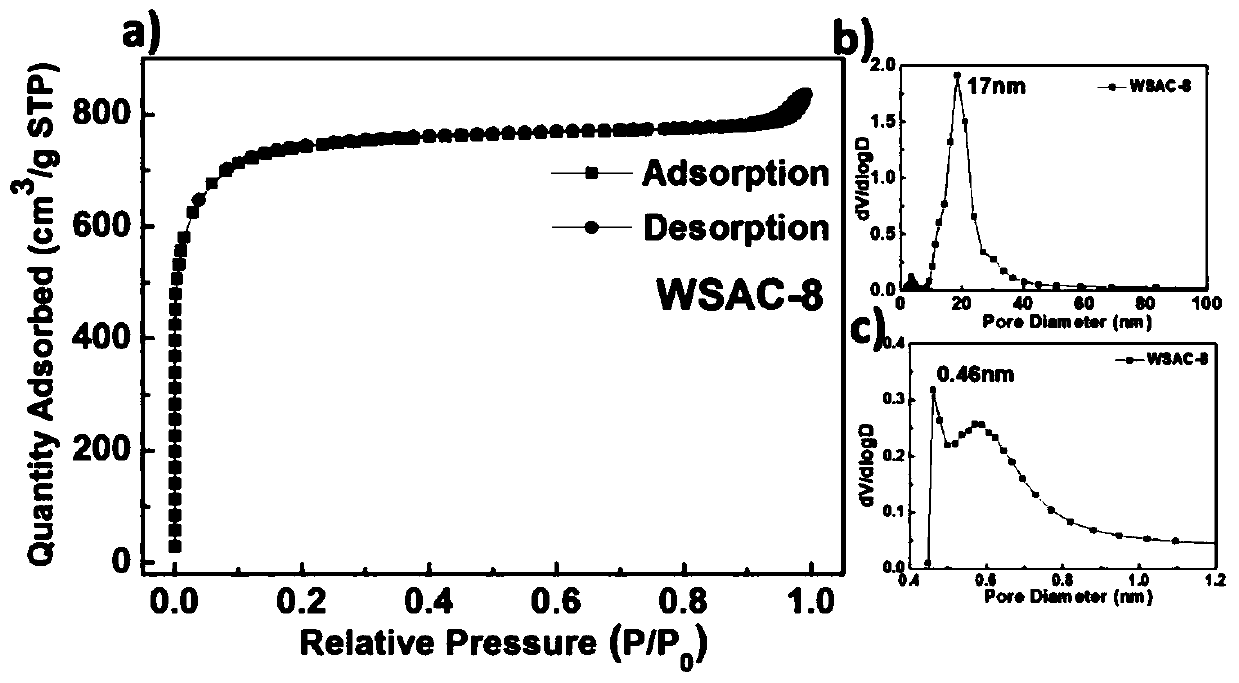

Image

Examples

Embodiment 1

[0044] A bioporous carbon-based lithium-sulfur battery cathode material, the preparation method of which comprises the following steps:

[0045] 1) Take natural hickory shells and use deionized water to ultrasonically wash away the surface dust for 30 minutes, then add 0.2mol / L dilute hydrochloric acid and soak for 2 hours to remove the minerals on the surface of the walnut shells; then wash with absolute ethanol to remove the surface of the walnut shells organic matter, and then moved to an oven at 120°C for 24 hours;

[0046] 2) Crushing the walnut shells obtained in step 1) to obtain walnut slices with a size of 0.5-1 cm, and then taking 5 g of the obtained walnut slices, placing them in a crucible and heating to 700 ° C in a tube furnace under an argon atmosphere for carbonization 2 hours to get biocoke, the heating rate is 3°C / min;

[0047] 3) Take 2g of the obtained biocoke and 8g of KOH, grind and mix them evenly, place them in a corundum boat and activate them in a tu...

Embodiment 2

[0057] A bioporous carbon-based lithium-sulfur battery cathode material, the preparation method of which comprises the following steps:

[0058] 1) Take natural hickory shells and use deionized water to ultrasonically wash away the surface dust for 30 minutes, then add 0.2mol / L dilute hydrochloric acid and soak for 2 hours to remove the minerals on the surface of the walnut shells; then wash with absolute ethanol to remove the surface of the walnut shells organic matter, and then moved to an oven at 120°C for 24 hours;

[0059] 2) Crushing the walnut shells obtained in step 1) to obtain walnut slices with a size of 0.5-1 cm, then taking 5 g of the obtained walnut slices, placing them in a crucible and heating them to 680°C in a tube furnace under an argon atmosphere for carbonization 2 hours to get biocoke, the heating rate is 3°C / min;

[0060] 3) Take 3g of the obtained biocoke and 12g of KOH, grind and mix them evenly, place them in a corundum boat and activate them in a tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com