High-energy-tolerance ZnO piezoresistor sheet and preparation method therefor

A varistor, high-energy technology, applied in the direction of varistor, varistor core, coating resistance material, etc., can solve the problems of severe heating, falling off, cracking of the encapsulation layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

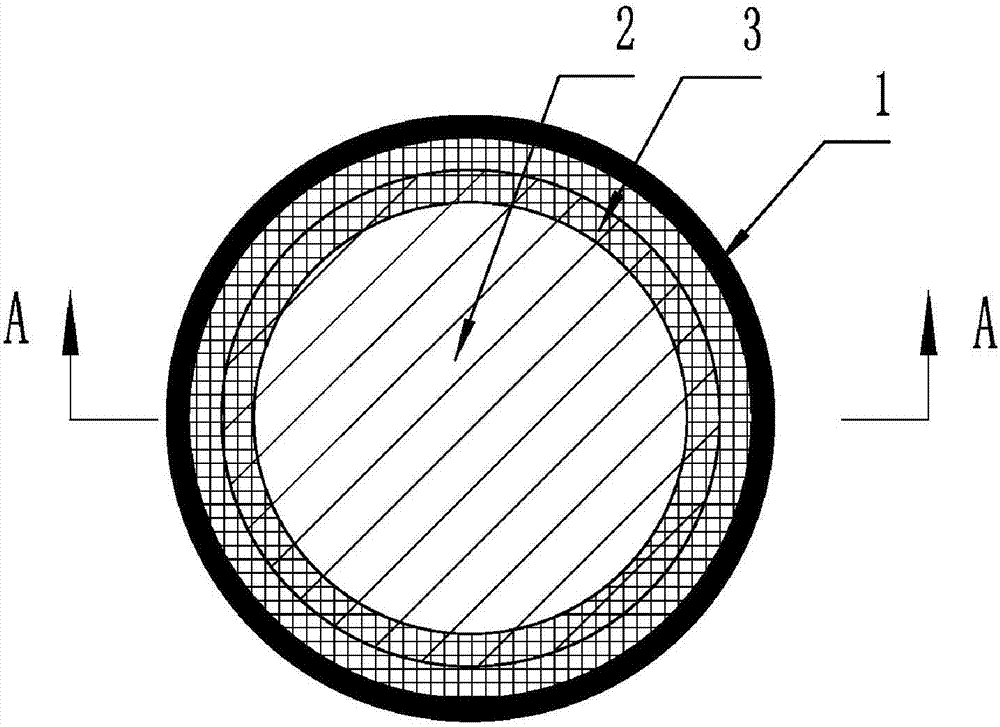

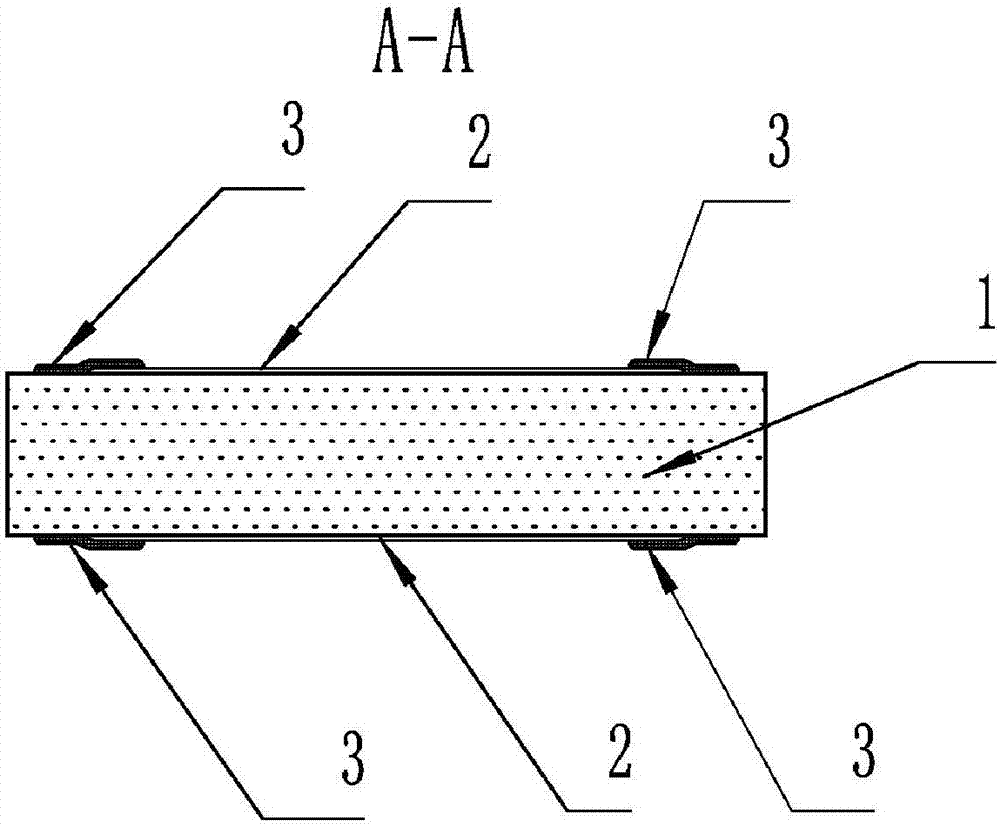

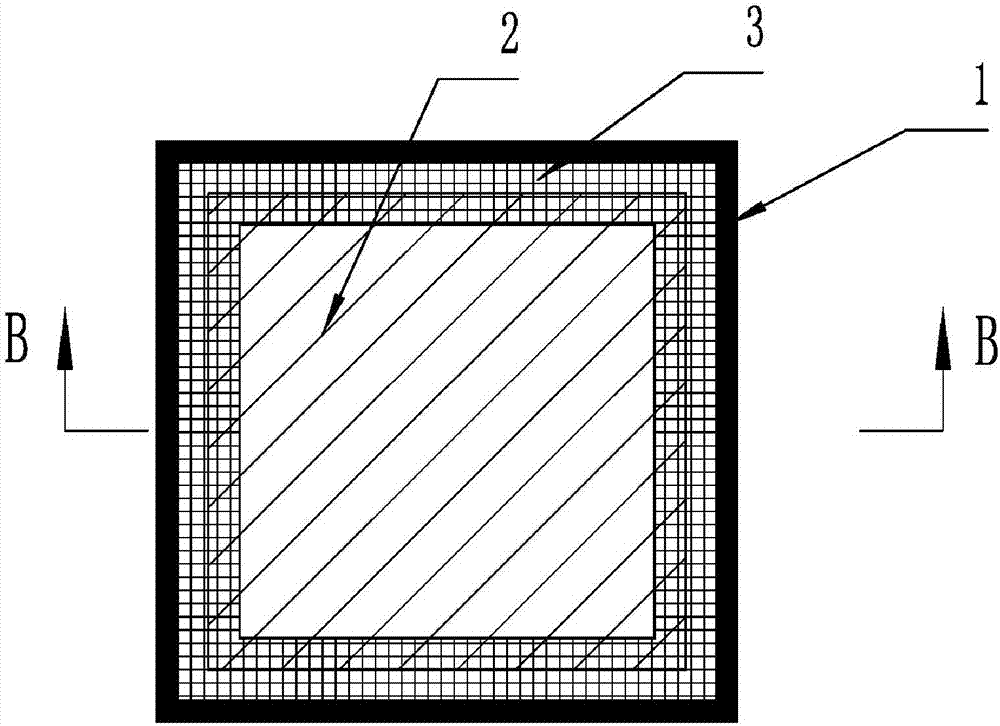

[0028] In this embodiment, the shape of the ZnO pressure-sensitive silver sheet is disc-shaped, and the insulating covering material is inorganic glass. The preparation method specifically includes the following steps:

[0029] S11. Making a disc-shaped ZnO varistor ceramic sheet 1 with a diameter of 10 mm and a thickness of 2 mm using the prior art.

[0030] S12, making the silver electrode 2, printing the silver electrode paste on both sides of the ZnO varistor ceramic sheet produced above by using the screen printing process, and the printing pattern on both sides is a circle with a diameter of 7.5 mm. After printing one side, it is baked, and the second side is printed and then baked. The baking temperature is 150°C.

[0031] Put the above-mentioned ZnO varistor ceramic sheet printed with silver electrode paste into a mesh-belt resistance furnace to sinter the silver electrode, and the temperature in the highest temperature zone of the mesh-belt resistance furnace is T1 (s...

Embodiment 5

[0040] In this embodiment, the manufacturing method is the same as that of Embodiment 1 except that organic polymer materials are used to make the ring-shaped insulating covering material 3 .

[0041] In this embodiment, thermosetting resin is selected to make the annular insulating covering material 3. Specifically, a two-component thermosetting resin is used, and the screen printing method is adopted. The printing pattern is a circular ring, the inner diameter of the ring is 6.0 mm, and the outer diameter of the ring is 9.0 mm. After printing one side, it is baked, and the second side is printed and then baked at a temperature of 150° C., and then placed in a baking oven at 150° C. for 30 minutes to complete the preparation of the annular insulating covering material 3 .

[0042] The test method is the same as that of Example 1. After welding the lead wires, the sample of this example has a good appearance after being subjected to 25 pulses of 4kV / 2kA, and no edge or side arc...

Embodiment 6

[0044] In this embodiment, the manufacturing method is the same as that of Embodiment 1 except that organic polymer materials are used to make the ring-shaped insulating covering material 3 .

[0045] In this embodiment, photocurable resin is used to make the ring-shaped insulating covering material 3. Specifically, UV-curable epoxy acrylic resin is used, and the screen printing method is adopted. The printing pattern is circular, the inner diameter of the ring is 6.0 mm, and the outer diameter of the ring is 9.0 mm. One side was printed and cured by ultraviolet light for 5 minutes, and then the second side was printed and cured by ultraviolet light for 5 minutes, thereby obtaining a ZnO varistor sheet covered with the annular insulating material 3 .

[0046] The test method is the same as that of Example 1. After welding the lead wires, the sample of this example has a good appearance after being subjected to 25 pulses of 4kV / 2kA, and no edge or side arc flashover occurs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com