Microwave-convective thermostatic drier and method for making ready-to-eat millet by means of thermostatic drier

A constant temperature drying and microwave technology, applied in drying chamber/container, grain drying, drying of solid materials, etc., can solve the problems of poor taste, long drying time and nutrient loss of rehydrated products, achieving bright color, long overcoming time, The effect of less loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

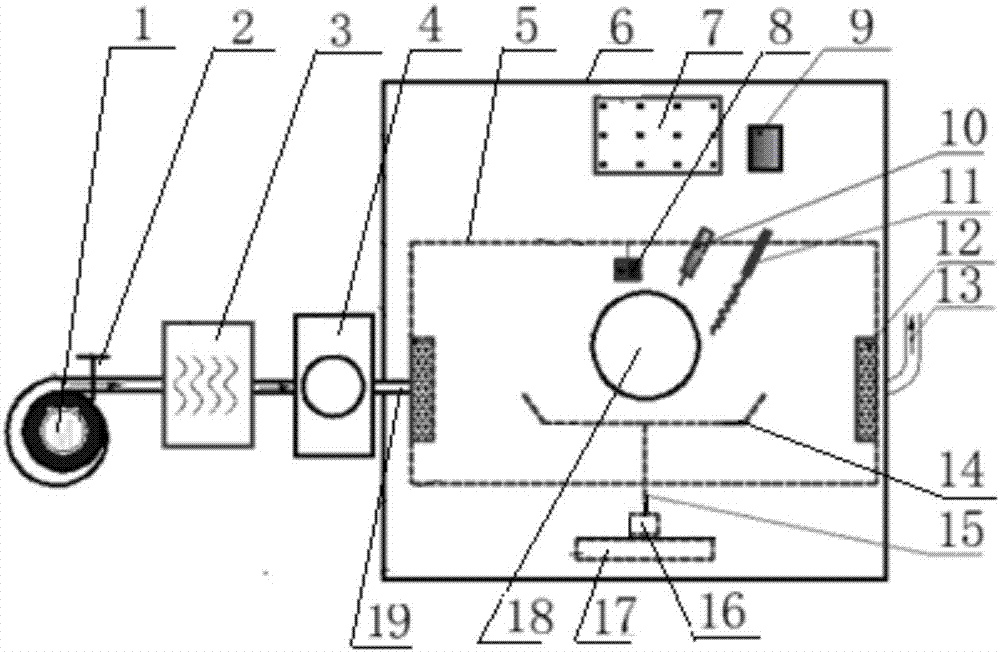

[0021] Such as figure 1 As shown, the microwave convection constant temperature dryer of the present invention is composed of blower 1, wind speed valve 2, electric heating box 3, thermocouple 4, drying chamber 5, drying box 6, data acquisition and control instrument 7, microwave transmitter 8, system switch 9. An infrared probe 10, an optical fiber probe 11, a splitter plate 12, an air outlet pipe 13, a material tray 14, a rotating shaft 15, a motor 16, an electronic scale 17, an observation window 18, and an air inlet pipe 19 are connected.

[0022] The blower 1 communicates with the electric heating box 3 through the wind speed control valve 2 installed on the pipeline, and the electric heating box 3 is connected with the drying chamber 5 installed in the drying box 6 through the air inlet pipe 19 through the thermocouple 4 installed on the pipeline In the drying chamber 5, a microwave transmitter 8, an infrared probe 10, an optical fiber probe 11 and a material tray 14 are...

Embodiment 2

[0024] 1. After washing the powder impurities and dust adhering to the surface of the millet, soak it with water at a mass ratio of 1.5:1 at room temperature for 3 hours, so that the millet can fully absorb water and swell.

[0025] 2. Put the soaked millet into a pressure cooker and steam for 45 minutes at a temperature of 121°C and a pressure of 0.12MPa to gradually complete the gelatinization process of the starch. After steaming, cool it with cold air at 4°C for 30 minutes, and then dry it discretely .

[0026] 3. Put the discretely dried millet into the material tray 14 of the microwave convection constant temperature dryer in Example 1, weigh the millet loading capacity to 200 g and the charging thickness to 5 mm through an electronic scale 17, turn on the system switch 9 and the rotating shaft 15 Drive the millet in the material tray 14 to rotate, the blower 1 starts to blow air into the electric heating box 3, the air intake speed is controlled through the wind speed c...

Embodiment 3

[0028] 1. After washing the powder impurities and dust adhering to the surface of the millet, soak it with water at a mass ratio of 1.5:1 at room temperature for 3 hours, so that the millet can fully absorb water and swell.

[0029] 2. Put the soaked millet into a pressure cooker and steam for 45 minutes at a temperature of 121°C and a pressure of 0.12MPa to gradually complete the gelatinization process of the starch. After steaming, cool it with cold air at 4°C for 30 minutes, and then dry it discretely .

[0030] 3. Adopt the microwave convection constant temperature dryer of embodiment 1 to dehydrate the millet after discrete drying, set the temperature of the hot air entering the drying chamber 5 and the temperature of the millet to 80°C, set the microwave power of the microwave transmitter 8 to 125W, and the power density 0.6W / g, the thickness of the material is 5mm, and the dehydration time is 30 minutes to obtain instant millet with a moisture content of less than 10%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com