Method for preparing lanthanum cerium bromide crystals using a crystal growth device with adjustable temperature field

A technology of crystal growth and lanthanum bromide, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problem of not being able to better match crystals of different sizes, being easily affected by the external environment, and unsuitable for adjusting the temperature field, etc. problems, to achieve the effect of being conducive to mass production, reducing the internal stress of the crystal, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0038] Embodiment 2 temperature field adjustable static lanthanum cerium bromide crystal growth method

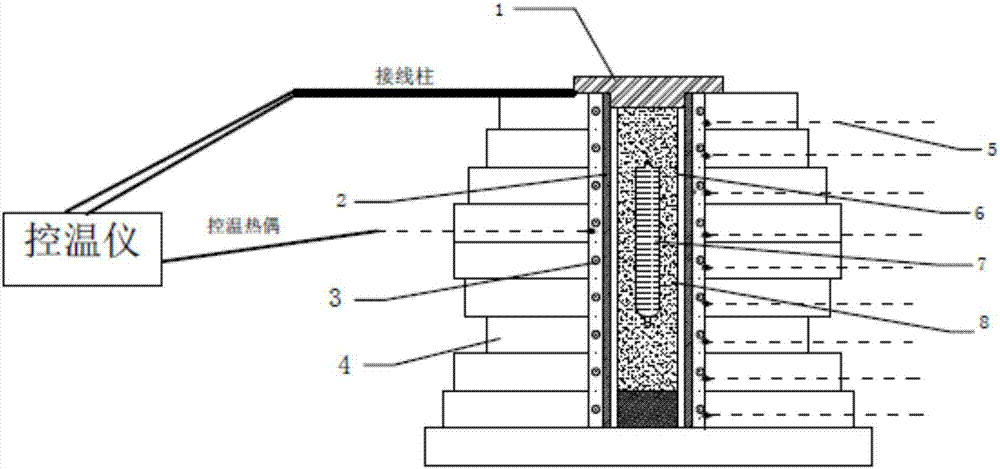

[0039] In this embodiment, the crystal growth device with adjustable temperature field is formed by stacking 11 layers of aluminum silicate insulation materials with a thickness of 5 cm and an inner diameter of 13 cm. From top to bottom, the outer diameter of the first layer is 40 cm, and the outer diameter of the second layer is The outer diameter of the third layer is 44cm, the outer diameter of the fourth, fifth, and sixth layers is 56cm, the outer diameter of the seventh layer is 46cm, the outer diameter of the eighth layer is 51cm, and the ninth layer The outer diameter of the tenth layer is 59cm, the outer diameter of the tenth layer is 65cm, and the outer diameter of the eleventh layer is 70cm. When charging, first cut the quartz crystal into long strip-shaped seed crystals along the C axis, with a size of 3mm×3mm×15mm, and the direction of the C axis is parallel to ...

Embodiment 3

[0041] Embodiment 3 temperature field adjustable static lanthanum cerium bromide crystal growth method

[0042] In this embodiment, the crystal growth device with adjustable temperature field is formed by stacking 12 layers of aluminum silicate insulation materials with a thickness of 5 cm and an inner diameter of 15 cm. From top to bottom, the outer diameter of the first layer is 40 cm, and the outer diameter of the second layer is The outer diameter of the third layer is 44cm, the outer diameter of the fourth, fifth, and sixth layers is 58cm, the outer diameter of the seventh layer is 45cm, the outer diameter of the eighth layer is 52cm, and the ninth layer The outer diameter of the tenth layer is 59cm, the outer diameter of the tenth layer is 65cm, the outer diameter of the eleventh layer is 70cm, and the outer diameter of the twelfth layer is 75cm. When charging, first cut the quartz crystal into long strip-shaped seed crystals along the C axis, with a size of 3mm×3mm×15mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com