PTC thermal sensitive ceramic material with high Curie temperature and preparation method thereof

A technology of thermal ceramics and raw materials, which is applied to resistors with positive temperature coefficients, non-adjustable metal resistors, resistors, etc. Good sensitivity, inhibition of lead volatilization, low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

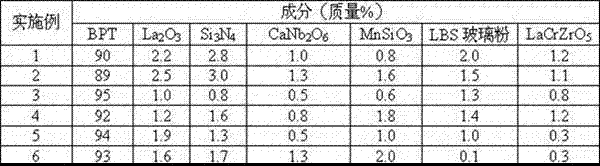

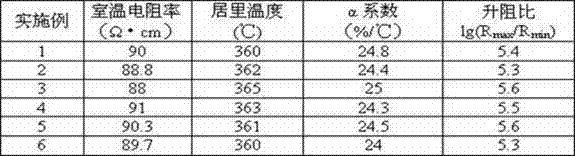

Examples

Embodiment 1

[0031] First, Ba was synthesized by a solid-phase method 0.4 Pb 0.6 TiO 3 , CaNb 2 o 6 , MnSiO 3 , Li 2 O-B 2 o 3 -SiO 2 Glass powder, LaCrZrO 5 .

[0032] Ba 0.4 Pb 0.6 TiO 3 Prepared by the following process: equipped with BaCO at a molar ratio of 0.4:0.6:1 3 , PbO and TiO 2 , then for BaCO 3 , PbO and TiO 2 Grind and mix well, then BaCO 3 , PbO and TiO 2 Put the mixed material into a corundum crucible, and keep it warm at 1130°C for 120 minutes to get Ba 0.4 Pb 0.6 TiO 3 . Got Ba 0.4 Pb 0.6 TiO 3 After cooling, grind and pass through a 200-mesh sieve for later use.

[0033] CaNb 2 o 6 Prepared by the following process: equip CaCO with a molar ratio of 1:1 3 and Nb 2 o 5 , then for CaCO 3 and Nb 2 o 5 Grind and mix well, then CaCO 3 and Nb 2 o 5 The mixed material was put into an alumina crucible and kept at 1020°C for 120 minutes to obtain CaNb 2 o 6 . Obtained CaNb 2 o 6 After cooling, grind and pass through a 200-mesh sieve for lat...

Embodiment 2

[0050] First, Ba was synthesized by a solid-phase method 0.4 Pb 0.6 TiO 3 , CaNb 2 o 6 , MnSiO 3 , Li 2 O-B 2 o 3 -SiO 2 Glass powder, LaCrZrO 5 .

[0051] Ba 0.4 Pb 0.6 TiO 3 Prepared by the following process: equipped with BaCO at a molar ratio of 0.4:0.6:1 3 , PbO and TiO 2 , then for BaCO 3 , PbO and TiO 2 Grind and mix well, then BaCO 3 , PbO and TiO 2 Put the mixed material into a corundum crucible and keep it warm at 1100°C for 120 minutes to get Ba 0.4 Pb 0.6 TiO 3 . Got Ba 0.4 Pb 0.6 TiO 3 After cooling, grind and pass through a 200-mesh sieve for later use.

[0052] CaNb 2 o 6 Prepared by the following process: equip CaCO with a molar ratio of 1:1 3 and Nb 2 o 5 , then for CaCO 3 and Nb 2 o 5 Grind and mix well, then CaCO 3 and Nb 2 o 5 The mixed material was put into an alumina crucible and kept at 1030°C for 120 minutes to obtain CaNb 2 o 6 . Obtained CaNb 2 o 6 After cooling, grind and pass through a 200-mesh sieve for late...

Embodiment 3

[0069] First, Ba was synthesized by a solid-phase method 0.4 Pb 0.6 TiO 3 , CaNb 2 o 6 , MnSiO 3 , Li 2 O-B 2 o 3 -SiO 2 Glass powder, LaCrZrO 5 .

[0070] Ba 0.4 Pb 0.6 TiO 3 Prepared by the following process: equipped with BaCO at a molar ratio of 0.4:0.6:1 3 , PbO and TiO 2 , then for BaCO 3 , PbO and TiO 2 Grind and mix well, then BaCO 3 , PbO and TiO 2 Put the mixed material into a corundum crucible, and keep it at 1150°C for 120 minutes to get Ba 0.4 Pb 0.6 TiO 3 . Got Ba 0.4 Pb 0.6 TiO 3 After cooling, grind and pass through a 200-mesh sieve for later use.

[0071] CaNb 2 o 6 Prepared by the following process: equip CaCO with a molar ratio of 1:1 3 and Nb 2 o 5 , then for CaCO 3 and Nb 2 o 5 Grind and mix well, then CaCO 3 and Nb 2 o 5 The mixed material was put into an alumina crucible and kept at 1000°C for 120 minutes to obtain CaNb 2 o 6 . Obtained CaNb 2 o 6 After cooling, grind and pass through a 200-mesh sieve for later use....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com