Double-function glass ceramic material and double-surface solar cell using same

A technology of solar cells and glass ceramics, which is applied in the field of solar cells and can solve problems such as enhancing the power generation efficiency of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

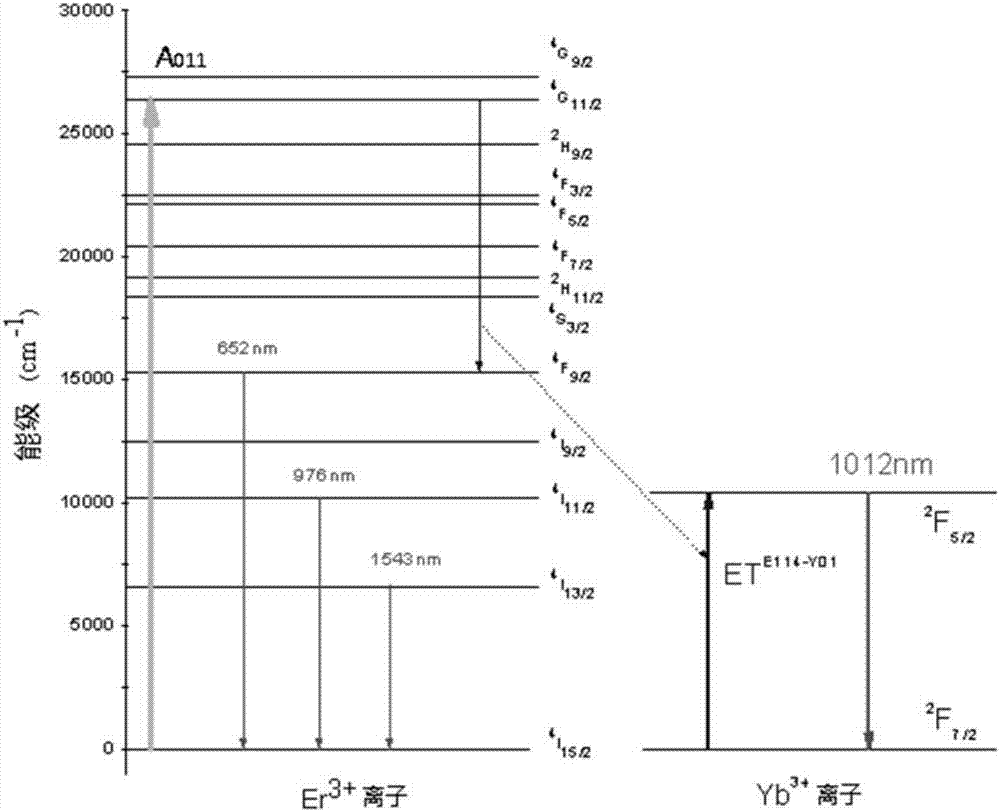

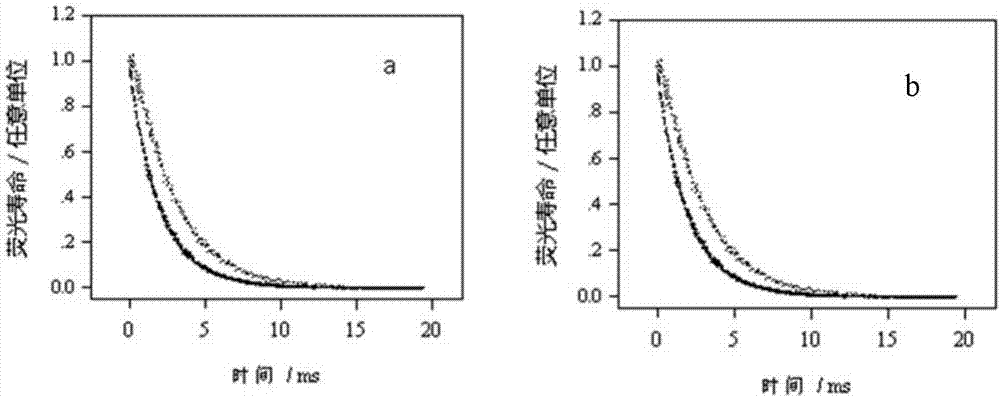

[0049] Example 1 - Oxyfluoride Nanophase Glass Ceramics Containing Erbium-Ytterbium Ion Pairs

[0050] The samples used in the experiment are (A)Er(1%)Yb(8.0%):FOV, (B)Er(0.5%)Yb(3.0%):FOV and (C)Er(0.5%):FOV. Oxyfluoride nanophase glass-ceramics composed of silicon oxide SiO 2 , Zinc fluoride ZnF 2 , lead fluoride PbF 2 , lutetium fluoride LuF 3 , Erbium fluoride ErF 3 , and ytterbium fluoride YbF 3 production. (B) Er(0.5%)Yb(3.0%): The composition of FOV sample is SiO 2 (45%), PbF 2 (30%), ZnF 2 (17.2%), LuF 3 (4.3%), ErF 3 (0.5%), and YbF 3 (3%).

[0051] The specific preparation steps are as follows: the oxyfluoride glass sample is made of high-purity silicon oxide SiO 2 , Zinc fluoride ZnF 2 , lead fluoride PbF 2 , lutetium fluoride LuF 3 , Erbium fluoride ErF 3 , and ytterbium fluoride YbF 3 Prepare the powder, place the fully mixed raw materials in an alumina crucible, and melt in an oxygen atmosphere at 900°C for 100 minutes. The purpose of introducin...

Embodiment 2

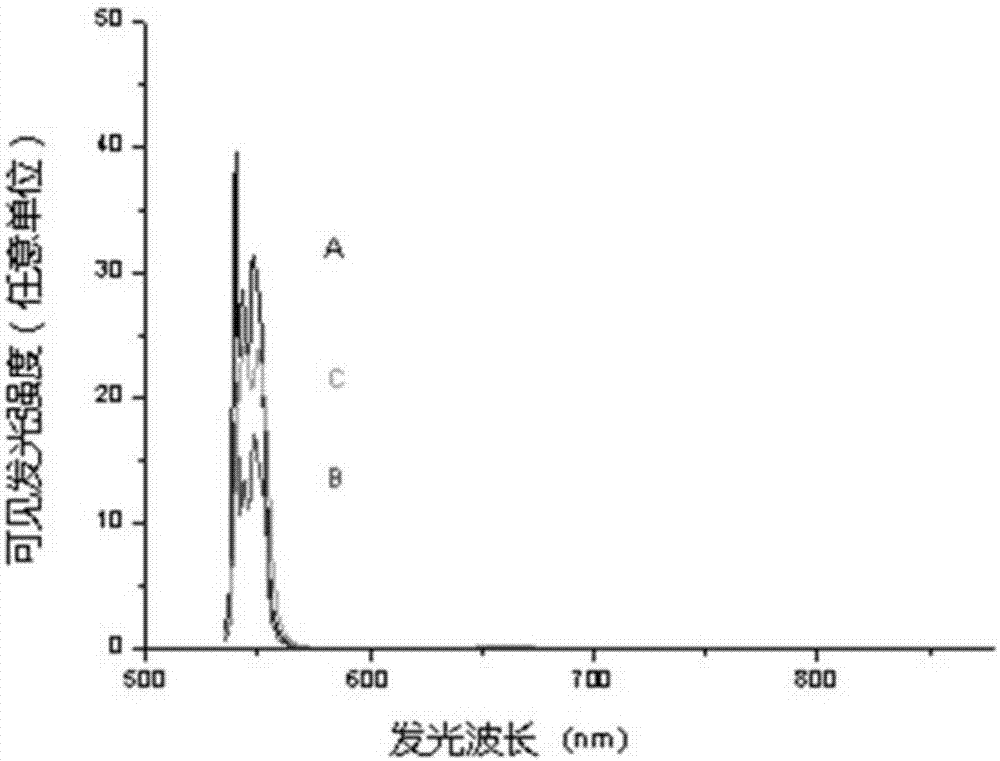

[0062] Example 2-Cooperative down-conversion luminescence of oxyfluoride nanophase glass ceramics Tb(0.7)Yb(5):FOV

[0063] The sample used in the experiment is Tb(0.7)Yb(5.0):FOV. The oxyfluoride nanophase glass-ceramic is composed of silicon oxide SiO 2 , Zinc fluoride ZnF 2 , lead fluoride PbF 2 , lutetium fluoride LuF 3 , terbium fluoride TbF 3 , and ytterbium fluoride YbF 3 production. Tb(0.7)Yb(5.0): The composition of FOV sample is SiO 2 (45%), PbF 2 (30%), ZnF 2(17.1%), LuF 3 (2.2%), TbF 3 (0.7%) and YbF 3 (5%).

[0064] The specific preparation steps are as follows: the oxyfluoride glass sample is made of high-purity silicon oxide SiO 2 , Zinc fluoride ZnF 2 , lead fluoride PbF 2 , lutetium fluoride LuF 3 , Terbium fluoride TbF 3 , and ytterbium fluoride YbF 3 Prepare the powder, place the fully mixed raw materials in an alumina crucible, and melt in an oxygen atmosphere at 900°C for 100 minutes. The purpose of introducing dry oxygen is to exclude hy...

Embodiment 3

[0080] Example 3 - Bifacial Solar Cell

[0081] Such as Figure 11 The double-sided solar cell of this embodiment is constructed as shown, wherein the solar cell 1 is a standard crystalline silicon solar cell or a multi-junction cascaded GaInP / GaAs / Ge (or InGaP / InGaAs / Ge) solar cell, illuminated from above Sunlight allows it to generate electricity. Below the solar cell 1 is a near-infrared quantum tailoring and up-conversion conversion layer 2, which is a six-sided polished glass-ceramic sample, such as the Er(1%)Yb(8%) of Example 1: FOV, with a size of about It is 50*50*5mm, and the thickness is about 5mm. The conversion layer 2 has two high light-transmitting surfaces on the side close to the side to guide sunlight and the side of the solar cell, and the other surfaces are coated with a high reflection layer 3 of aluminum film.

[0082] What is shown on the left side of the figure is a side guiding device, which includes a reflector or a reflective layer 4 and a lens, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com