Super-strength zinc aluminum magnesium coated steel plate for high-temperature shaping and manufacture method thereof

A high-temperature forming and coating steel plate technology, applied in coating, hot-dip plating process, metal material coating process, etc., can solve the problems of high corrosion resistance, low productivity, high price, etc., and achieve corrosion resistance. Excellent, satisfying the effect of lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

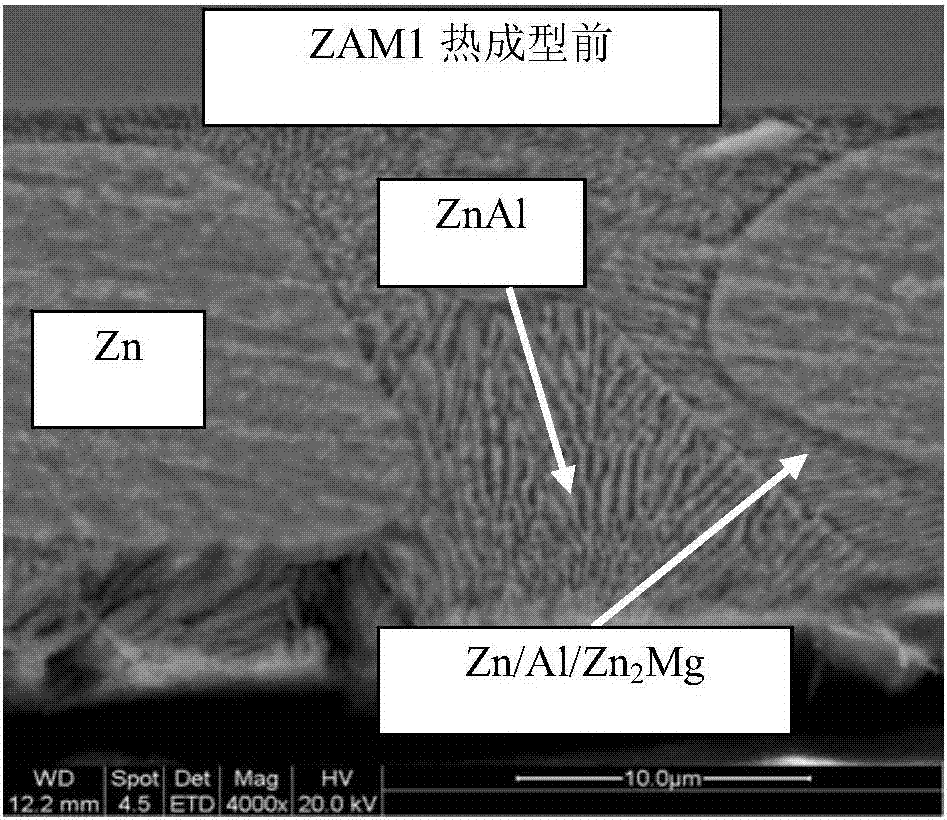

[0038] An ultra-high-strength zinc-aluminum-magnesium-coated steel sheet for high-temperature forming, its composition and weight percentage are: C: 0.25%, Si: 0.25%, Mn: 2.35%, Cr: 0.4%, B: 0.0024%, Ti: 0.037% , Nb: 0.025%, Al: 0.06%, N: 0.0028%, and the rest are Fe and unavoidable impurities. The chemical composition weight percent of the plating solution is: Al: 2.4%, Mg: 1.3%, and the rest are Zn and unavoidable impurities.

[0039] The production steps of coated steel plate are as follows:

[0040] 1) Smelting and continuous casting into billets according to the chemical composition;

[0041] 2) Hot continuous rolling controls the final rolling temperature to 880°C, the total reduction rate to 90%, and the coiling temperature to 710°C;

[0042] 3) The total reduction rate of cold rolling control is 65%;

[0043] 4) Heat the steel strip in the dew point range of -30°C to 820°C, in H 2 In a reducing atmosphere with a volume percentage of 30%, cool to 495°C at a cooling ...

Embodiment 2

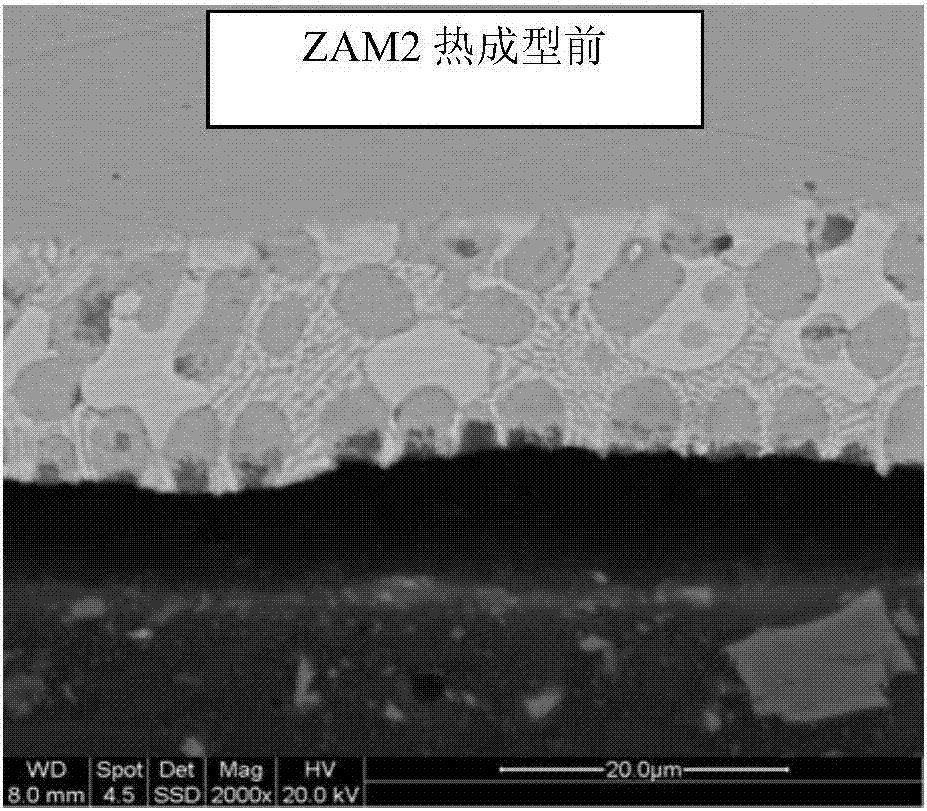

[0047] An ultra-high-strength zinc-aluminum-magnesium-coated steel sheet for high-temperature forming, its composition and weight percentage are: C: 0.35%, Si: 0.25%, Mn: 2.35%, Cr: 0.4%, B: 0.0041%, Ti: 0.045% , Nb: 0.034%, Al: 0.034%, N: 0.0035%, and the rest are Fe and unavoidable impurities. The chemical composition weight percent of the plating solution is: Al: 7.1%, Mg: 1.6%, and the rest are Zn and unavoidable impurities.

[0048] The production steps of coated steel plate are as follows:

[0049] 1) Smelting and continuous casting into billets according to the chemical composition;

[0050] 2) Hot continuous rolling controls the final rolling temperature to 800°C, the total reduction rate to 80%, and the coiling temperature to 700°C;

[0051] 3) The total reduction ratio of cold rolling control is 55%;

[0052] 4) Heat the steel strip in the dew point range of 10°C to 780°C, H 2 The volume percentage is 20%, cooled to 475°C at a cooling rate of 30°C / s, holding time...

Embodiment 3

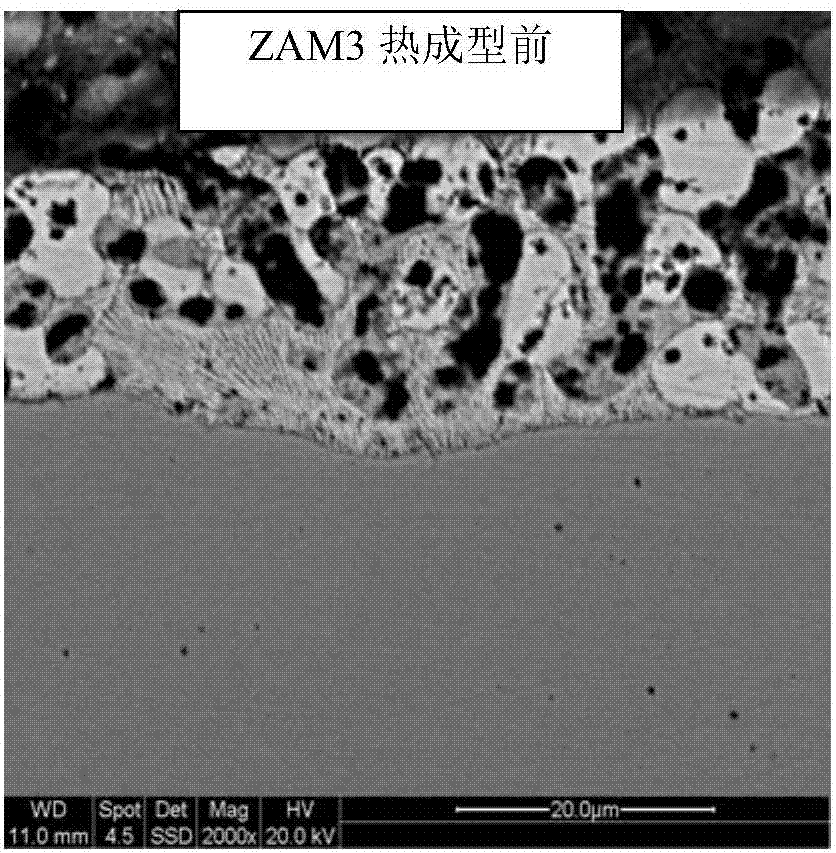

[0056] An ultra-high-strength zinc-aluminum-magnesium-coated steel sheet for high-temperature forming, its composition and weight percentage are: C: 0.53%, Si: 0.35%, Mn: 2.8%, Cr: 0.4%, B: 0.0055%, Ti: 0.063% , V: 0.1%, Al: 0.051%, N: 0.0049%, the remainder is Fe and unavoidable impurities. The chemical composition weight percent of the plating solution is: Al: 15.3%, Mg: 3.7%, and the rest are Zn and unavoidable impurities.

[0057] The production steps are as follows:

[0058] 1) Smelting and continuous casting into billets according to the chemical composition;

[0059] 2) Hot continuous rolling controls the final rolling temperature to 840°C, the total reduction rate to 95%, and the coiling temperature to 730°C;

[0060] 3) The total reduction ratio of cold rolling control is 75%;

[0061] 4) Heat the steel strip in the dew point range of 30°C to 840°C, H 2 The volume percentage is 10%, cooled to 465°C at a cooling rate of 15°C / s, holding time for 90s, then immersed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com