Foaming masterbatch with photocatalytic function and preparation method of foaming masterbatch

A foaming masterbatch and photocatalytic technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The masterbatch component consists of 60 parts of composite photocatalyst, 25 parts of carrier resin LDPE, 3 parts of dispersant polyethylene low molecular weight wax, 1 part of silane coupling agent (KH-550), 3 parts of lubricant stearic acid, activated foaming agent Makes up 8 servings.

[0075] The preparation method is to carry out according to the following steps:

[0076] (1) Under the condition of pH 6, 1 kg of n-butyl titanate was hydrolyzed, stirred at room temperature for 3 h, and adjusted by dialysis to obtain TiO with a pH value of 7. 2 Sol.

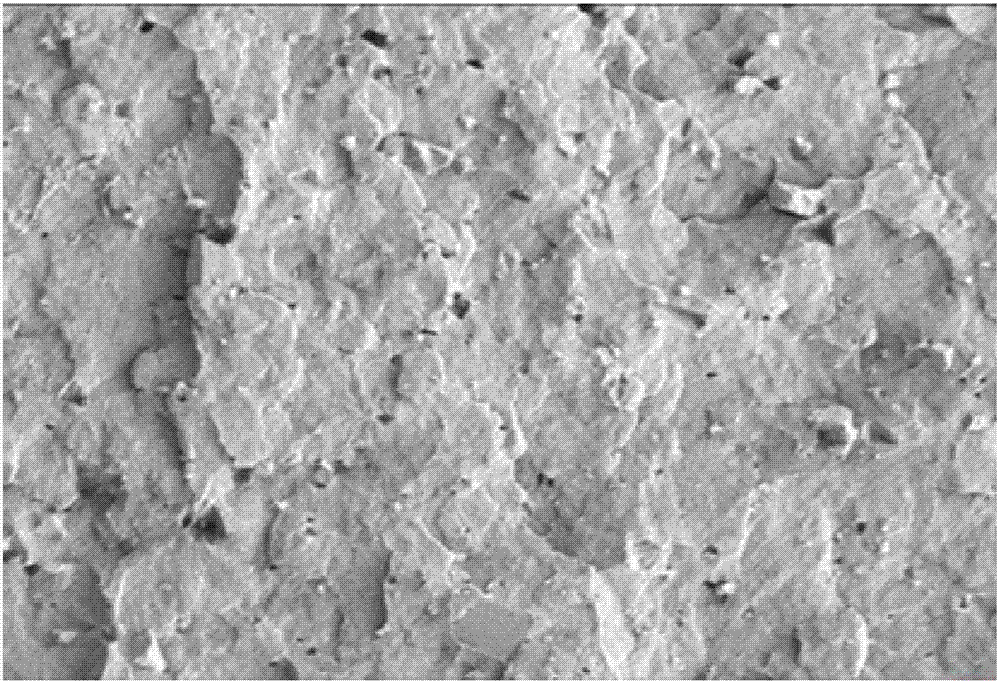

[0077] (2) Add 10kg of calcium carbonate and 0.1kg of biomass ash (plant ash: seaweed ash mass ratio = 1:5) into a high-speed mixer and stir at high speed, then add 0.1kg of TiO prepared in step (1) 2 Sol, control the speed of 600 r / min, heat at 100°C to remove water, and then add 0.1kg of TiO prepared in step (1) when the water is less 2 The sol was repeated 5 times to obtain a coated powder with high dispersion an...

Embodiment 2

[0083] The masterbatch component consists of 60 parts of composite photocatalyst, 20 parts of carrier resin LDPE, 3.5 parts of dispersant polyethylene low molecular weight wax, 1 part of silane coupling agent (KH-550), 3.5 parts of lubricant stearic acid, activated foam The composition consists of 12 parts.

[0084] The preparation method is to carry out according to the following steps:

[0085] (1) Under the condition of pH 6, 1 kg of n-butyl titanate was hydrolyzed, stirred at room temperature for 3 h, and adjusted by dialysis to obtain TiO with a pH value of 7. 2 Sol.

[0086] (2) Add 10kg of calcium carbonate and 0.2kg of biomass ash (plant ash: seaweed ash mass ratio = 1:5) into a high-speed mixer and stir at high speed, then add 0.1kg of TiO prepared in step (1) 2 sol, control the speed at 600 r / min, heat at 100°C to remove water, add 0.1 kg of TiO2 sol prepared in step (1) when the moisture is low, and repeat 5 times to obtain highly dispersed and high-loaded TiO2 so...

Embodiment 3

[0090] The masterbatch component consists of 70 parts of composite photocatalyst, 15 parts of carrier resin LDPE, 3.5 parts of dispersant polyethylene low molecular wax, 1.5 parts of silane coupling agent (KH-550), 2 parts of lubricant stearic acid, activated foam The composition consists of 8 parts.

[0091] The preparation method is to carry out according to the following steps:

[0092] (1) Under the condition of pH 6, 1 kg of n-butyl titanate was hydrolyzed, stirred at room temperature for 3 h, and adjusted by dialysis to obtain a TiO2 sol with a pH value of 7.

[0093] (2) Add 10kg of calcium carbonate and 0.2kg of biomass ash (plant ash: seaweed ash mass ratio = 1:5) into a high-speed mixer and stir at high speed, then add 0.12kg of TiO2 sol prepared in step (1), and control the speed 600 r / min, heat at 100°C to remove water, add 0.12kg of TiO2 sol prepared in step (1) when the moisture is low, and repeat 5 times to obtain a coated powder with high dispersion and high l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com