A kind of bio-based non-stick wheel sticky layer oil and preparation method thereof

A non-stick wheel and sticky layer oil technology, applied in the direction of adhesives, adhesive types, asphalt material adhesives, etc., can solve problems such as prolonging the emulsified asphalt demulsification time, loss of adhesive layer materials, and reduced bonding effect , to achieve important application value and economic benefits, improve adhesion, low-temperature viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of modified bio-asphalt: Mix hard asphalt with a penetration of 10dmm and corn stalk biomass heavy oil at 130°C and 5000r / min shear conditions for 30min to obtain bio-asphalt; bio-asphalt, phenolic epoxy resin F -44. Nano silicon dioxide (particle size is 15nm, specific surface area is 300m 2 / g) shear uniformly at 110°C to obtain modified bio-asphalt. Among them, the mass ratio of 10dmm hard asphalt, corn stalk biomass heavy oil, phenolic epoxy resin F-44, and nano-silica is 100:15:5:1.

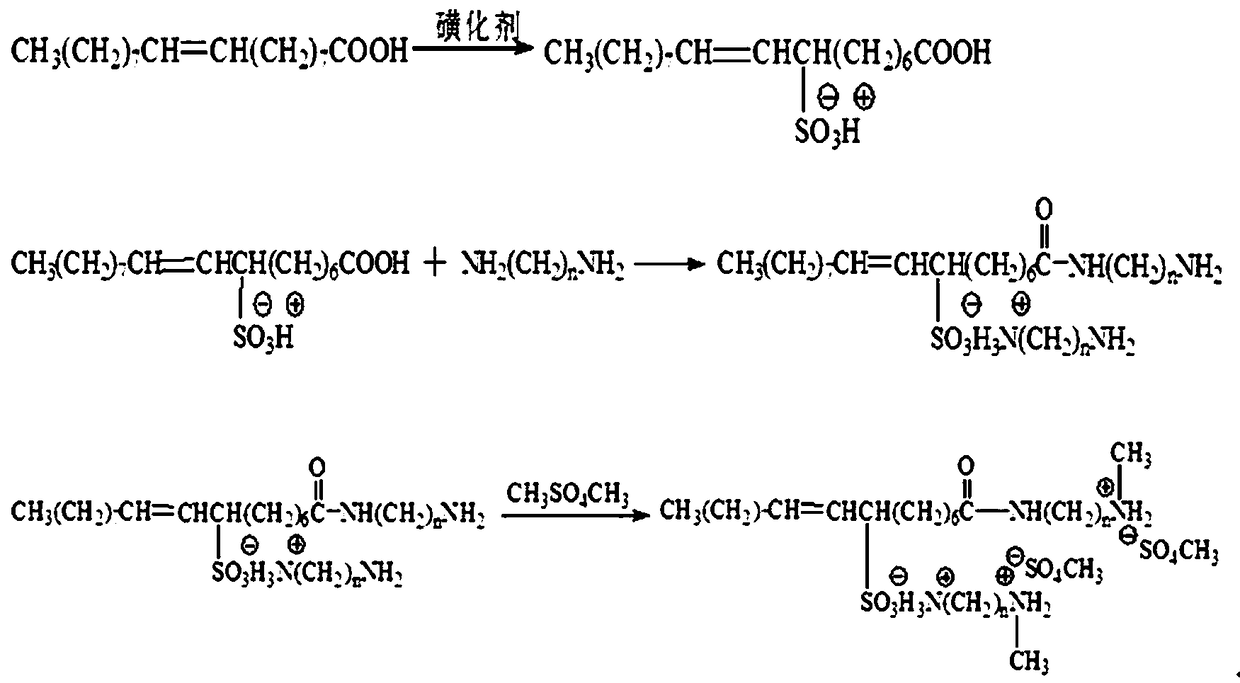

[0021] Preparation of special emulsifier: (1) Add 50g of concentrated sulfuric acid, a sulfonating agent, dropwise to 100g of oleic acid at 45°C, and react for 4 hours to obtain sulfonated oleic acid; (2) Mix the above sulfonated oleic acid with 53g of 1,3 -Propylenediamine in N 2 Under protection, react at 160°C for 4 hours; finally, cool down to 80°C, add 120g of solvent ethylene glycol, and then dropwise add 90g of dimethyl sulfate for 2h to obtain a special asphalt ...

Embodiment 2

[0025] Preparation of modified bio-asphalt: Mix hard asphalt with a penetration of 30dmm and pig manure biomass heavy oil at 120°C and 3000r / min shear conditions for 20min to obtain bio-asphalt; bio-asphalt, novolac epoxy resin F -51. Nano silica (particle size is 50nm, specific surface area is 150m 2 / g) shear uniformly at 120°C to obtain modified bio-asphalt. Among them, the mass ratio of 30dmm hard asphalt, pig manure biomass heavy oil, phenolic epoxy resin F-51, and nano-silica is 100:10:7.5:2.

[0026] Preparation of special emulsifier: (1) Add 80 g of oleum, a sulfonating agent, dropwise to 100 g of oleic acid at 35°C, and react for 6 hours to obtain sulfonated oleic acid; (2) Mix the above sulfonated oleic acid with 63 g of 1, 4-Butanediamine in N 2 Under protection, react at 170°C for 3.5 hours; finally, cool down to 85°C, add 130g of solvent propylene glycol, and then dropwise add 98g of dimethyl sulfate for 3h to obtain a special asphalt emulsifier.

[0027] Prep...

Embodiment 3

[0030] Preparation of modified bio-asphalt: Mix hard asphalt with a penetration of 50dmm and corn stalk biomass heavy oil at 125°C and 4000r / min shear conditions for 25min to obtain bio-asphalt; bio-asphalt, bisphenol F-ring Oxygen resin, nano silica (particle size is 30nm, specific surface area is 200m 2 / g) shear uniformly at 115°C to obtain modified bio-asphalt. Among them, the mass ratio of 50dmm hard asphalt, corn stalk biomass heavy oil, bisphenol F epoxy resin and nano silicon dioxide is 100:5:10:2.5.

[0031] Preparation of special emulsifier: (1) Add 60g of sulfur trioxide, a sulfonating agent, dropwise to 100g of oleic acid at 40°C, and react for 5 hours to obtain sulfonated oleic acid; (2) Mix the above sulfonated oleic acid with 73g of 1, 5-Pentanediamine in N 2Under protection, react at 180°C for 3 hours; finally, cool down to 90°C, add 140g of solvent diethylene glycol, and then dropwise add 94g of dimethyl sulfate for 2.5h to obtain a special asphalt emulsifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com