Convenient preparation method for high-performance collagen gel

A collagen gel, high-performance technology, applied in the field of preparation of biomedical materials, can solve the problems of high freeze-drying cost, time-consuming, collagen denaturation, etc., and achieve the effects of convenient preparation method, low equipment requirements, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

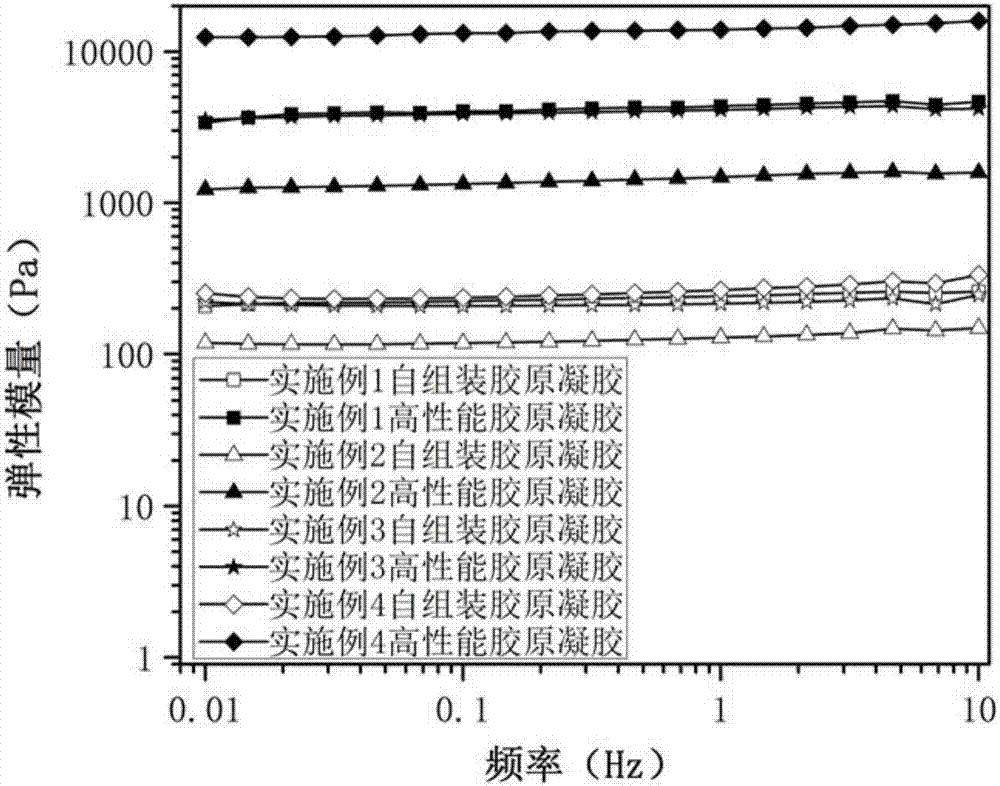

[0027] The freeze-dried undenatured natural bovine collagen sponge was dissolved in 10 mmol / L disodium hydrogen phosphate / sodium dihydrogen phosphate buffer (NaCl concentration was 120 mmol / L) at pH 6.8 under an ice-water bath to obtain a concentration of 8 mg / mL Uniform cowhide collagen solution, take 3mL cowhide collagen solution and place it in a 35mm mold, keep the temperature at 37°C for 6h, then soak the prepared collagen gel with 240mL ethanol solutions with volume concentrations of 10, 20, and 30% for 30min , and finally the collagen gel was treated with 240 mL of ethanol solution with a volume concentration of 80% for 24 hours, and the solution was changed every 4 hours to prepare a high-performance cowhide collagen gel. With a rheometer at 2% strain and at a temperature of 20 ° C, the elastic modulus of the untreated natural cowhide collagen gel at a frequency of 1 Hz is 241.21Pa, and the elastic modulus of the high-performance collagen gel is 4365.82Pa, which is The...

Embodiment 2

[0029] The undenatured natural cowhide collagen sponge of freeze-drying is dissolved in the Tris / HCl buffer solution (NaCl concentration is 150mmol / L) of 50mmol / L of pH 7.6 under ice-water bath to obtain the uniform cowhide collagen solution that concentration is 3mg / mL, take Put 3mL of cowhide collagen solution in a 35mm mold, keep the temperature at 30°C for 2h, then soak the prepared collagen gel with 60mL of ethanol solution with volume concentration of 10, 15, and 25% for 30min, and finally gel the collagen The gel was treated with 60 mL of isopropanol solution with a volume concentration of 60% for 12 hours, and the solution was changed every 1 hour to prepare a high-performance bovine collagen gel. With a rheometer at 2% strain and at a temperature of 20 ° C, the elastic modulus of the untreated natural cowhide collagen gel at a frequency of 1 Hz is 128.46Pa, and the elastic modulus of the high-performance collagen gel is 1479.15Pa. The modulus of elasticity increased b...

Embodiment 3

[0031] The freeze-dried undenatured natural pigskin collagen sponge was dissolved in 12 mmol / L disodium hydrogen phosphate / citric acid buffer (NaCl concentration was 100 mmol / L) at pH 7.2 under an ice-water bath to obtain a uniform concentration of 5 mg / mL. Pigskin collagen solution, take 3mL pigskin collagen solution and place it in a 35mm mold, keep the temperature at 35°C for 3h, then soak the prepared collagen gel in 150mL ethanol solutions with volume concentrations of 15, 20, and 30% After 30 minutes, the collagen gel was finally treated with 150 mL of tert-butanol solution with a volume concentration of 70% for 18 hours, and the solution was changed every 3 hours to prepare a high-performance pigskin collagen gel. The elastic modulus of the untreated natural pigskin collagen gel measured at a frequency of 1 Hz at 2% strain and a temperature of 20°C with a rheometer is 215.28Pa, and the elastic modulus of the high-performance pigskin collagen gel is 4116.52 Pa, its modul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com