Phosphorus-containing PBS flame-retardant material and phosphorus-containing polyurethane and preparation method

A flame retardant material, polyurethane technology, applied in the field of biodegradable flame retardant material preparation, can solve the problems of poor compatibility of PBS flame retardant modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

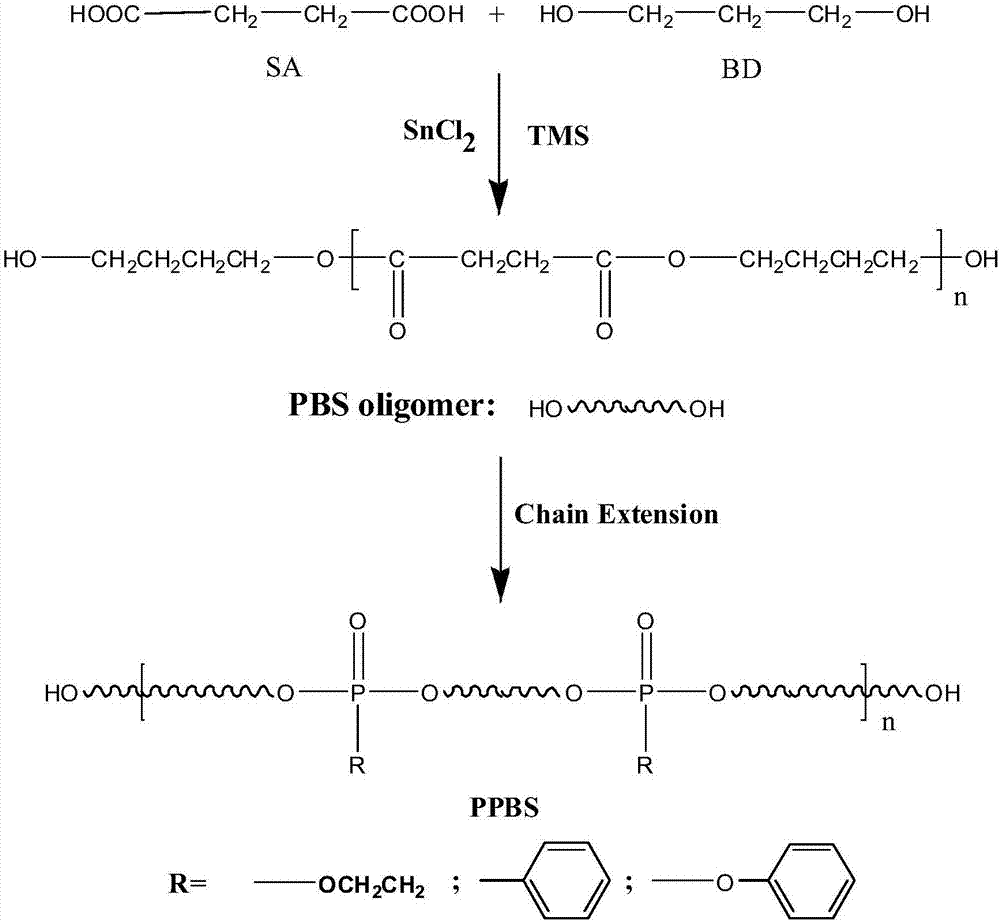

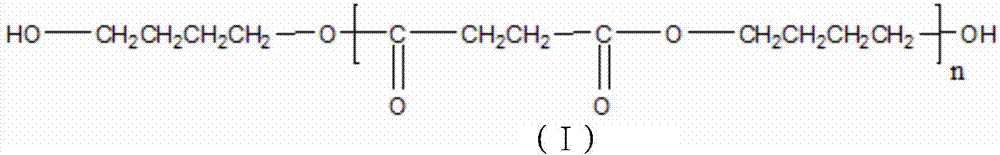

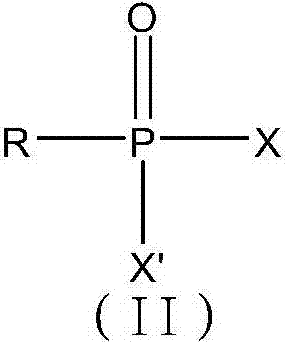

Method used

Image

Examples

Embodiment 1

[0039] Carry out the preparation of phosphorus-containing polyurethane with embodiment 1 as optimum embodiment:

[0040] Commercialized PBS resin (commercialized PBS resin in this application is purchased from Anqing Hexing Chemical Co., Ltd., injection molding grade, molecular weight Mn≈70000) is mixed with phosphorus-containing PBS flame retardant material (PPBS) by melt blending method Evenly, add the aliphatic isocyanate at the same time, slowly raise the temperature of the reaction system to 150-180°C, after the mixture is completely melted, react for 2 hours under the protection of nitrogen, and then the phosphorus-containing polyurethane can be prepared.

[0041] Table 3 shows that each component of different content obtains the different phosphorus-containing polyurethanes of series:

[0042] table 3

[0043]

[0044] Table 4 shows the test results of the phosphorus-containing polyurethanes obtained in different examples. It can be seen from the results that the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com