A comprehensive chemical and metallurgical utilization method for joint development of phosphogypsum and nepheline mines

A chemical metallurgy, phosphogypsum technology, applied in phosphate fertilizer, application, superphosphate and other directions, can solve the problem of not being able to open and use, and achieve the effect of protecting the environment and improving the value of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0046] Example 1: The comprehensive utilization of chemical metallurgy jointly developed by Kunyang Phosphate Fertilizer Plant and Gejiu Xiashi Mine

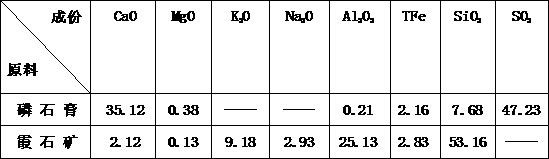

[0047] 1. Analysis of main components of raw materials:

[0048]

[0049] 2. Process flow:

[0050] After the phosphogypsum and nepheline ore crushed by the jaw crusher and finely ground by the ball mill are fully mixed, they are roasted in the reverberatory furnace to carry out the double decomposition reaction, and the process is fully stirred to promote the complete reaction. After the reaction is completed, the cooled reactant is placed in a stainless steel pressurized jacketed heating reactor, and water (slag washing water) is added to pressurize and increase the temperature for cooking to extract potassium sulfate and aluminum sulfate. After the leaching is completed, the leaching material is subjected to liquid-solid separation in the anti-corrosion plate and frame filter press: the leaching liquid is sent to the proc...

example 2

[0081] Example 2: The comprehensive utilization of chemical metallurgy in the joint development of phosphogypsum by Honghe Phosphate Fertilizer Plant and Gejiu Nepheline Mine

[0082] 1. Analysis of main components of raw materials:

[0083]

[0084] 2. Process flow:

[0085] After the phosphogypsum and nepheline ore crushed by the jaw crusher and finely ground by the ball mill are fully mixed, they are roasted in the reverberatory furnace to carry out the double decomposition reaction, and the process is fully stirred to promote the complete reaction. After the reaction is completed, the cooled reactant is placed in a stainless steel pressurized jacketed heating reactor, and water (slag washing water) is added to pressurize and increase the temperature for cooking to extract potassium sulfate and aluminum sulfate. After the leaching is completed, the liquid-solid separation of the leaching material is carried out in the anti-corrosion plate and frame filter press: the lea...

example 3

[0116] Example 3: The comprehensive utilization of chemical metallurgy jointly developed by Xuanwei Phosphorus Chemical Plant and Huili Nepheline Mine

[0117] 1. Analysis of main components of raw materials:

[0118]

[0119] 2. Process flow:

[0120]After the phosphogypsum and nepheline ore crushed by the jaw crusher and finely ground by the ball mill are fully mixed, they are roasted in the reverberatory furnace to carry out the double decomposition reaction, and the process is fully stirred to promote the complete reaction. After the reaction is completed, the cooled reactant is placed in a stainless steel pressurized jacketed heating reactor, and water (slag washing water) is added to pressurize and increase the temperature for cooking to extract potassium sulfate and aluminum sulfate. After the leaching is completed, the liquid-solid separation of the leaching material is carried out in the anti-corrosion plate and frame filter press: the leaching liquid is sent to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com