AlGaN / GaN ultraviolet detector based on oblique ZnO nanowire array modulation and preparation method thereof

A technology for ultraviolet detectors and nanowire arrays, applied in sustainable manufacturing/processing, semiconductor devices, final product manufacturing, etc., can solve problems affecting the sensitivity of ultraviolet light detection, small mismatch, and affecting the regulation of ZnO nanowires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention provides a preparation method of the ultraviolet detector described in the above scheme, comprising the following steps:

[0059] Provide gateless AlGaN / GaN high electron mobility transistors;

[0060] mixing zinc salt, hexamethylenetetramine and water to obtain a precursor solution;

[0061] The upper surface of the gateless AlGaN / GaN high electron mobility transistor is immersed in the precursor solution to carry out hydrothermal reaction.

[0062] The invention prepares gateless AlGaN / GaN high electron mobility transistor. The present invention has no special requirements on the preparation method of the gateless AlGaN / GaN high electron mobility transistor, and can be prepared by methods well known to those skilled in the art. In a specific embodiment of the present invention, the preparation method of the gateless AlGaN / GaN high electron mobility transistor preferably includes the following steps:

[0063] (1) Deposit an AlN nucleation layer...

Embodiment 1

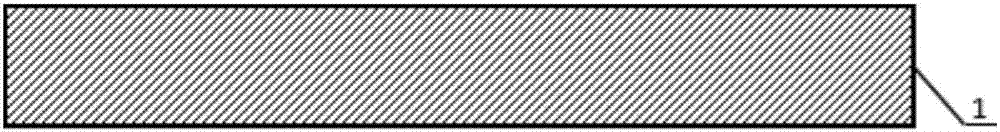

[0083] Al on the m-plane by metal-organic chemical vapor deposition (MOCVD) 2 o 3 A 150nm AlN nucleation layer was grown on the substrate, as Figure 1 ~ Figure 2 shown;

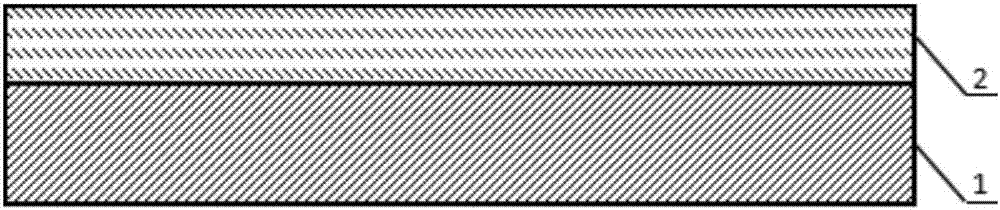

[0084] A 2 μm thick semipolar surface (11-22) GaN buffer layer is deposited on the surface of the AlN nucleation layer by MOCVD, such as image 3 shown;

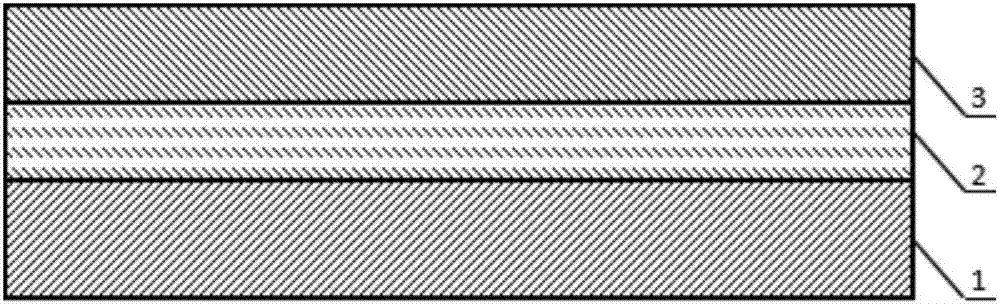

[0085] A 25nm-thick semipolar (11-22) GaN channel layer is grown on the surface of the GaN buffer layer by MOCVD, such as Figure 4 shown;

[0086] 20nm thick Al was grown on the surface of the GaN channel layer by MOCVD 0.25 Ga 0.75 N barrier layers, such as Figure 5 shown;

[0087] Al 0.25 Ga 0.75 A 2nm-thick semipolar plane (11-22) GaN cap layer is grown on the surface of the N barrier layer to obtain a semipolar AlGaN / GaN epitaxial wafer, such as Image 6 shown;

[0088] Photolithography is carried out on the semi-polar AlGaN / GaN epitaxial wafer, and the active area pattern is prepared by spinning glue, pre-baking, exposure, post-baking, a...

Embodiment 2

[0097] m surface Al 2 o 3 As the substrate, use the method in Example 1 to prepare a gateless AlGaN / GaN high electron mobility transistor, control the thickness of the AlN nucleation layer to 140nm, the thickness of the GaN buffer layer to 1.5μm, the thickness of the GaN channel layer to 20nm, and the thickness of the AlGaN The thickness of the barrier layer is 15nm, the thickness of the GaN cap layer is 1.5nm, and the source electrode and drain electrode are consistent with the embodiment 1;

[0098] Growth of oblique ZnO nanowire arrays in the gate region by hydrothermal method: Zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 (2) 10mmol and hexamethylenetetramine (HMTA) 20mmol are dissolved in 1L deionized water, stir evenly, as the precursor solution of ZnO nanowire growth; Get 30ml precursor solution and put into hydrothermal reaction kettle, again without Place the upper surface of the AlGaN / GaN high electron mobility transistor with the gate facing down, suspend it in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com