Digitally driven semiconductor display device

A display device, digital drive technology, used in static indicators, instruments, etc., can solve problems such as reducing system cost, and achieve the effect of reducing system cost, high refresh rate, and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

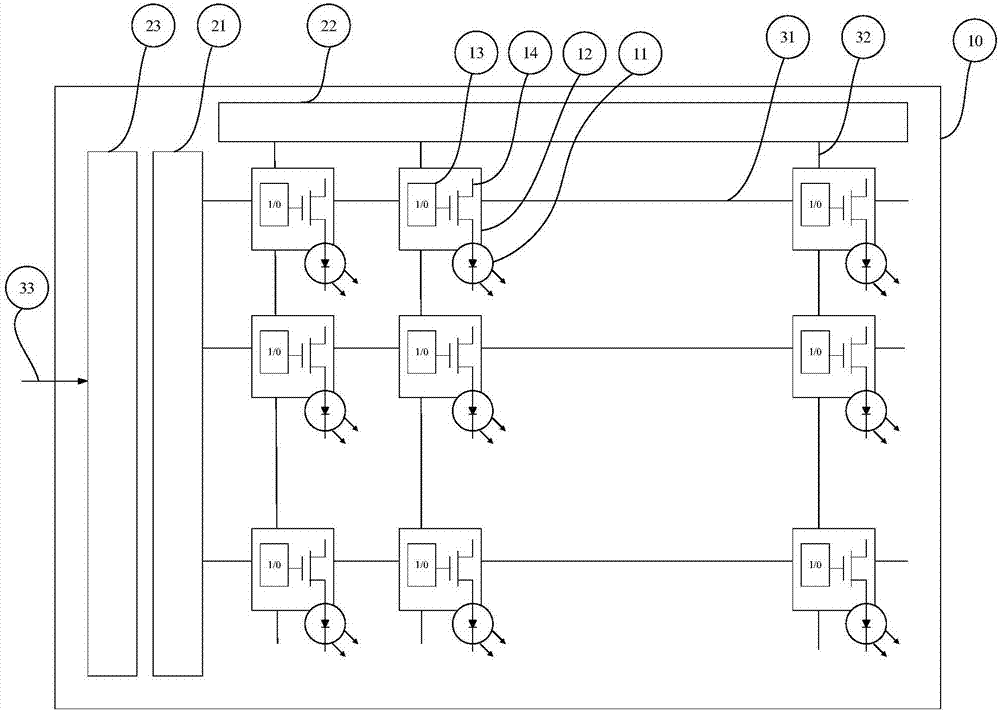

[0034] This embodiment discloses a digitally driven semiconductor display device, such as figure 1 As shown, it includes a silicon substrate 10 and micro light emitting diodes 11 fabricated in an array on the silicon substrate 10. A pixel circuit 12 is integrated in the silicon substrate 10 for driving the micro light emitting diodes 11. The pixel circuit 12 includes The metal-oxide semiconductor field effect transistor; the pixel circuit 12 and the micro light emitting diode 11 have a one-to-one correspondence; the silicon substrate 10 is preferably a single crystal silicon wafer or a cut single crystal silicon chip.

[0035] The micro light emitting diode 11 comprises a first electrode, a multi-layer non-organic compound and a second electrode, and the non-organic compound is composed of Ga, As, In, Al, Se, Zn, Si, P, N or C elements and can be Doping, the compounds are preferably GaAs, GaAsP, AlGaAs, AlGaInP, GaInN, AlGaP, AlGaN, GaP:ZnO, InGaN, GaN, GaP, ZnSe, Al 2 o 3 ,...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, the difference is that the micro light emitting diode 11 is a horizontal structure, which is characterized in that the two electrodes (the first electrode 43 and the second electrode 42) of the micro light emitting diode 11 are in a multilayer The same side of the non-organic compound layer 41 (light-emitting layer), such as Figure 4 As shown, the first electrode 43 is connected to the pixel circuit 12 through the through hole 44, and the second electrode 42 is connected to the pixel circuit 12 through the through hole 45, and the first electrode 43 and the second electrode 42 are conductive metal.

[0044] Further, the multilayer non-organic compound layer 41 preferably at least includes a bottom-up (or top-down) N-type doped layer (such as n-GaN), an MQW layer (multiple quantum well), a P-type doped layer (such as p-GaN), or include more layers to optimize performance. Furthermore, the micro light emitting diode...

Embodiment 3

[0052] This embodiment is basically the same as Embodiment 1, except that the distance between the micro-LEDs 11 is not greater than 20 μm, preferably 5-10 μm. The current of 11 is 0.1 μA to 30 μA, preferably 1˜5 μA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com