Method for refining tea oil for cosmetics

A technology of cosmetics and camellia oil, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of rising oleic acid value and peroxide value, accelerating oil oxidation back color, long time required for degumming, etc., to prevent oleic acid The effects of increasing valency and peroxide value, enhancing adsorption capacity, and shortening degumming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

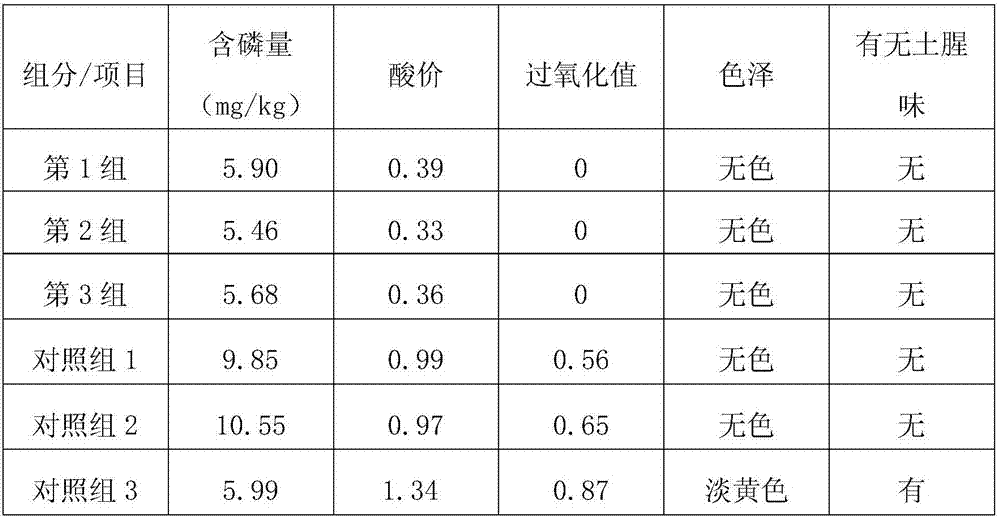

Examples

Embodiment 1

[0030] A method for refining camellia oil for cosmetics, comprising the following steps:

[0031] (1) Degumming:

[0032] The crude oil is heated to 60 DEG C, and the concentration of 0.2% of the total weight of the crude oil added to the heated crude oil is 15% citric acid, mixed evenly, and the crude oil is mixed with a concentration of 6% sodium hydroxide solution. The pH is adjusted to 5, and after the pH adjustment is completed, phospholipase A of 0.05% of the total weight of the crude oil is added 1 , 0.02% Phospholipase A 2 , 0.3% calcium dihydrogen phosphate, 0.5% potassium chloride and 0.7% ferrous sulfate, wherein, phospholipase A 1 The enzyme activity is 150IU, phospholipase A 2 The enzyme activity is 100IU, stir at 300r / min for 15min, then reduce the stirring speed to 50r / min, and use ultrasonic treatment for 8min, the power of ultrasonic is 150W, the frequency is 30KHz, stop ultrasonic, keep warm for 10min, immediately after the warm Centrifuge at 4800r / min fo...

Embodiment 2

[0042] A method for refining camellia oil for cosmetics, comprising the following steps:

[0043] (1) Degumming:

[0044] Crude oil is heated to 65 ℃, and the concentration that adds described crude oil gross weight 0.3% is 20% citric acid in the crude oil after heating, mixes, and with concentration is the sodium hydroxide solution of 8% the crude oil The pH is adjusted to 5.5, and after the pH adjustment is completed, phospholipase A of 0.07% of the total weight of the crude oil is added 1 , 0.04% Phospholipase A 2 , 0.5% calcium dihydrogen phosphate, 0.8% potassium chloride and 0.9% ferrous sulfate, wherein, phospholipase A 1 The enzyme activity is 200IU, phospholipase A 2The enzyme activity is 150IU, stir at 350r / min for 20min, then reduce the stirring speed to 100r / min, and use ultrasonic treatment for 10min, the power of ultrasonic is 200W, the frequency is 45KHz, stop ultrasonic, keep warm for 20min, immediately after the warm Centrifuge at 5000r / min for 20min, take...

Embodiment 3

[0054] A method for refining camellia oil for cosmetics, comprising the following steps:

[0055] (1) Degumming:

[0056] Crude oil is heated to 63 ℃, and the concentration that adds described crude oil gross weight 0.25% is the citric acid of 18% in the crude oil after heating, mixes, and with the concentration of 7% sodium hydroxide solution, the crude oil The pH is adjusted to 5.3, and after the pH adjustment is completed, phospholipase A of 0.06% of the total weight of the crude oil is added 1 , 0.03% Phospholipase A 2 , 0.4% calcium dihydrogen phosphate, 0.7% potassium chloride and 0.8% ferrous sulfate, wherein, phospholipase A 1 The enzyme activity is 180IU, phospholipase A 2 The enzyme activity is 130IU, stir at 330r / min for 17min, then reduce the stirring speed to 80r / min, and use ultrasonic treatment for 9min, the power of ultrasonic is 180W, the frequency is 40KHz, stop ultrasonic, keep warm for 15min, immediately after the warm Centrifuge at 4900r / min for 18min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com