Preparation method of blue green LED luminescent material

A luminescent material, blue-green technology, applied in the field of materials, can solve the problems of lack of spectrum, LED phosphors are difficult to achieve color rendering index, etc., and achieve the effect of simple preparation process, good brightness, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Ba 5.99 Ga 7 Al 7 SiO 29 : Preparation example of 0.01Eu luminescent material

[0030] According to the chemical formula Ba 5.99 Ga 7 Al 7 SiO 29 : 0.01Eu composition and stoichiometric ratio Weigh europium oxide, barium carbonate, gallium oxide, aluminum oxide, silicon dioxide; then weigh 6% barium fluoride of the total weight of raw materials; mix all raw materials by ball milling, Sieve with a 120-mesh screen; put the mixed raw materials into a tube furnace, and sinter at 1460°C for 8 hours under 100% nitrogen protection; the resulting product is ground and sieved, washed with 10% nitric acid, and then Washed with deionized water and dried to obtain Ba 5.99 Ga 7 Al 7 SiO 29 : 0.01Eu blue-green phosphor.

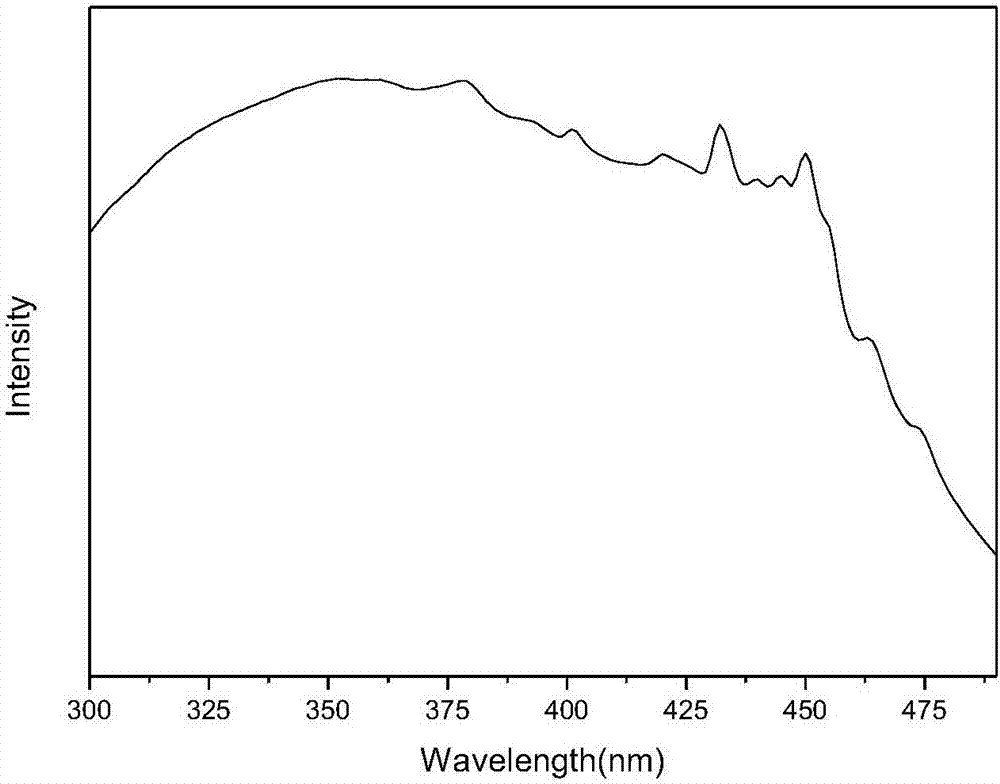

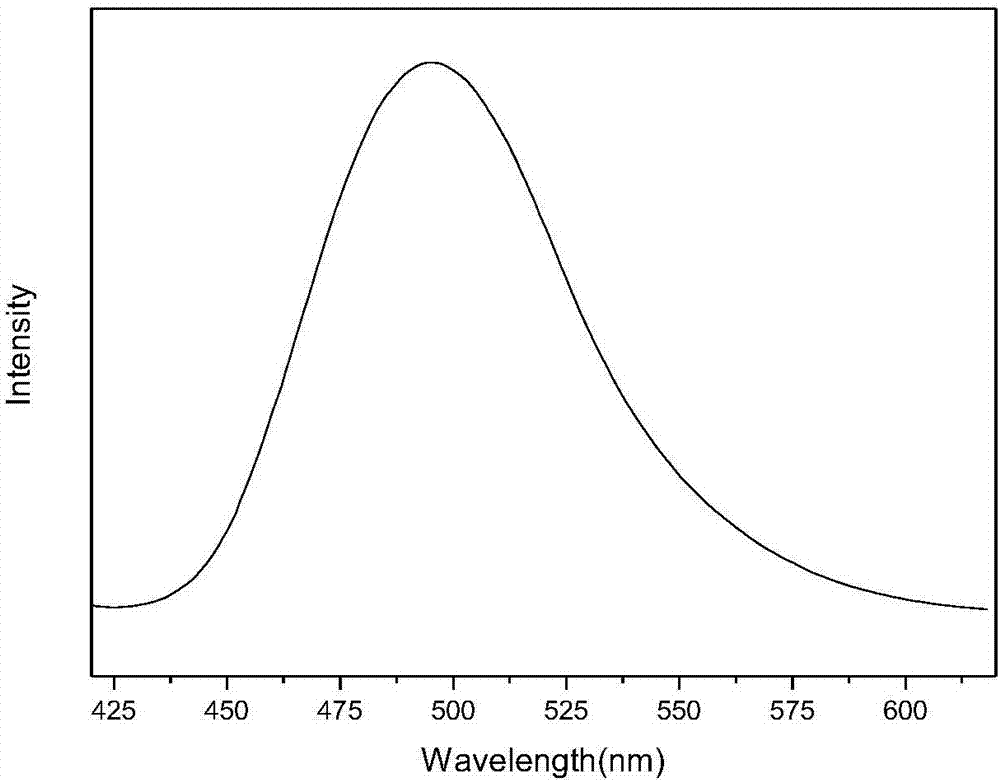

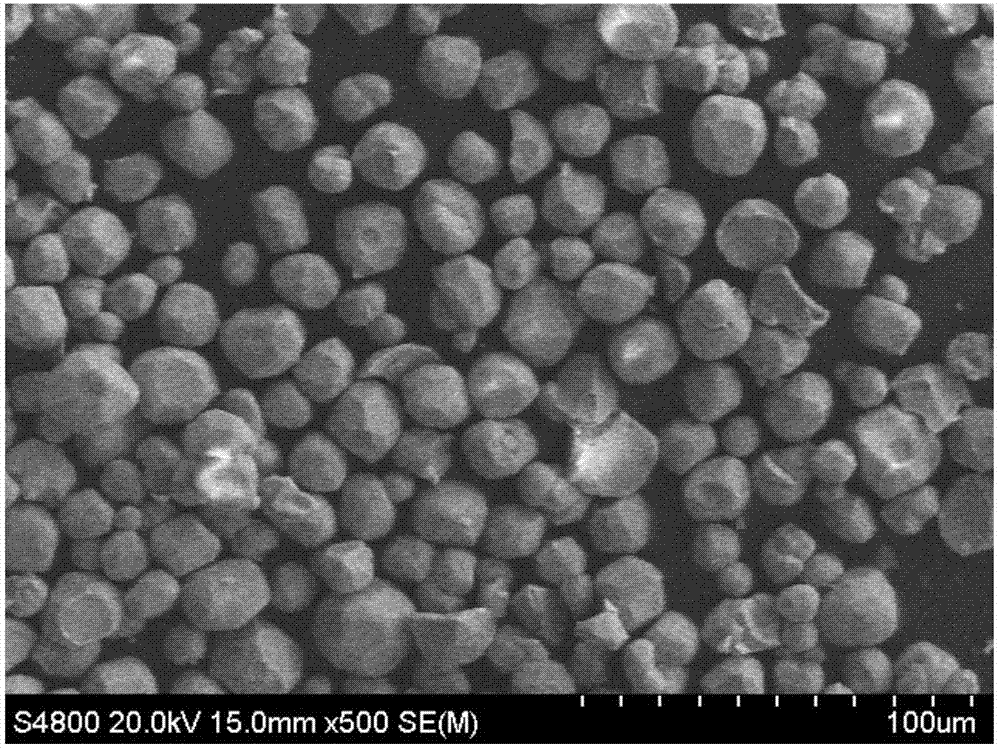

[0031] figure 1 It is the excitation spectrogram of embodiment 1 of the present invention, as figure 1 As shown, it shows that the excitation wavelength of the luminescent material is 300-450nm; figure 2 It is the emission spectrogram of e...

Embodiment 2

[0032] Example 2: Sr 5.99 Ga 2 Al 12 SiO 29 : Preparation example of 0.01Eu luminescent material

[0033] According to the chemical formula Sr 5.99 Ga 2 Al 12 SiO 29 : 0.01Eu composition and stoichiometric ratio Weigh europium oxide, strontium carbonate, gallium oxide, aluminum oxide, silicon dioxide; then weigh 3% barium fluoride of the total weight of raw materials; mix all raw materials by ball milling, Sieve with a 120-mesh screen; put the mixed raw materials into a tube furnace, and sinter at 1480°C for 10 hours under 100% nitrogen protection; the resulting product is ground and sieved, washed with 10% nitric acid, and then After washing with deionized water and drying to obtain Sr 5.99 Ga 2 Al 12 SiO 29 : 0.01Eu blue-green phosphor.

Embodiment 3

[0034] Example 3: Sr 5.03 Ba 0.95 Ga 10 Al 4 SiO 29 : Preparation example of 0.02Eu luminescent material

[0035] According to the chemical formula Sr 5.03 Ba 0.95 Ga 10 Al 4 SiO 29 : 0.02Eu composition and stoichiometric ratio Weigh europium oxide, strontium carbonate, barium carbonate, gallium oxide, aluminum oxide, silicon dioxide; then weigh 1% barium fluoride of the total weight of raw materials; ball mill all raw materials After mixing, sieve with a 120-mesh screen; put the mixed raw materials into a tube furnace, and sinter at 1480°C for 10 hours under the protection of 100% argon; Washed, then washed with deionized water and dried to obtain Sr 5.03 Ba 0.95 Ga 10 Al 4 SiO 29 : 0.02Eu blue-green phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com