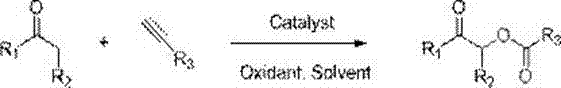

Method for preparing alpha-acyloxy ketone compound from terminal alkyne compounds

A technology of ketone compounds and acyloxy ketones, which is applied in the field of catalytic synthesis of α-acyloxy ketone compounds, can solve the problems of unreported acyloxylation and single reaction system, and achieve a good industrial The effect of application prospect, simple preparation, mild reaction process and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 0.4 mmol of propiophenone, 0.2 mmol of phenylacetylene, appropriate amount of tert-butanol peroxide, and 1 ml of chlorobenzene into the Schlenk tube under air environment, and add appropriate amount of catalyst (ferric chloride, copper bromide, copper acetate, copper chloride, ketone trifluoroacetate, copper nitrate, copper sulfate or copper acetylacetonate), at 120 o The reaction was stirred at C for 12 hours. By column chromatography, when copper acetylacetonate is used as a catalyst, the yield of the reaction can reach 70% yield.

Embodiment 2

[0030] Add 0.4 mmol of propiophenone, 0.2 mmol of phenylacetylene, an appropriate amount of copper acetylacetonate, and 1 ml of chlorobenzene into the Schlenk tube in the air environment, and add an appropriate amount of oxidants (tert-butanol peroxide, hydrogen peroxide, di-tert- Butyl peroxide, potassium persulfate complex salt), at 120 o The reaction was stirred at C for 12 hours. By column chromatography, when tert-butanol peroxide is used as the oxidant, the yield of the reaction can reach 70% yield.

Embodiment 3

[0032] Put 0.4 mmol of propiophenone, 0.2 mmol of phenylacetylene, an appropriate amount of copper acetylacetonate, and an appropriate amount of oxidant into the Schlenk tube under air environment, and add solvents (tetrahydrofuran, toluene, ethyl acetate, chlorobenzene, 1, 2-dichloroethane, acetonitrile, dimethyl sulfoxide, carbon tetrachloride), at 120 o The reaction was stirred at C for 12 hours. By column chromatography, when chlorobenzene is used as solvent, the yield of the reaction can reach 70% yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com