A kind of size-controllable Schiff base polymer nanoparticle and its preparation method

A Schiff base and nanoparticle technology, which is applied in the field of size-controllable Schiff base polymer nanoparticles and their preparation, and achieves the effects of easy separation and purification, mild and easy control of the reaction process, and improved purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

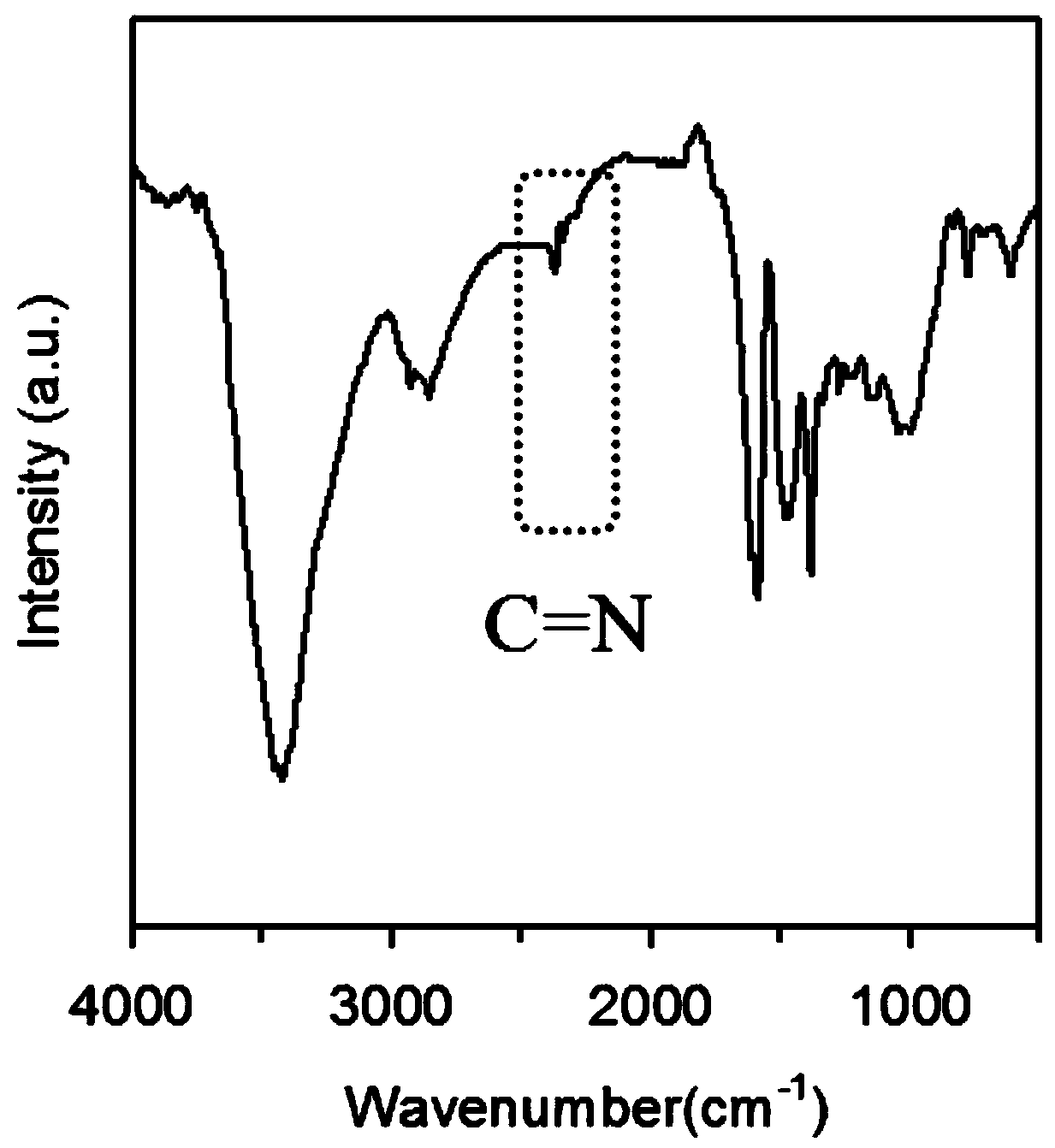

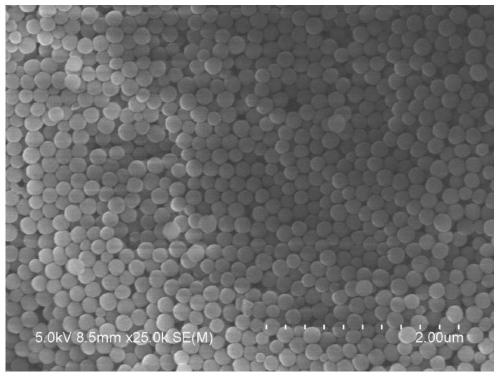

[0037] A size-controllable Schiff base polymer nanoparticle is prepared by reacting 2,6-diaminopyridine and formalin through a Schiff base; wherein, the content of formaldehyde in 2,6-diaminopyridine and formalin The molar ratio is 1:2; the concentration of formaldehyde in formalin is 37wt%; the particle size of the size-controllable Schiff base polymer nanoparticles is 120nm;

[0038] The size-controllable Schiff base polymer nanoparticles are prepared by the following steps:

[0039] S1. Put 0.15g 2,6-diaminopyridine into the reactor, add 300ml deionized water, seal the reactor, stir and dissolve, add 0.225g formalin after the 2,6-diaminopyridine dissolves, Continue to seal the reactor, stir and react at 20°C for 18h to obtain the mixed material;

[0040] S2. After centrifuging the mixed material, pour off the supernatant, wash twice with water, wash once with methanol, purify with methanol for 60 hours using a Soxhlet extractor, and dry to obtain size-controllable Schiff b...

Embodiment 2

[0043] A size-controllable Schiff base polymer nanoparticle is prepared by reacting 2,6-diaminopyridine and formalin through a Schiff base; wherein, the content of formaldehyde in 2,6-diaminopyridine and formalin The molar ratio is 1:18; the concentration of formaldehyde in formalin is 37wt%; the particle size of the prepared size-controllable Schiff base polymer nanoparticles is 2000nm;

[0044] The size-controllable Schiff base polymer nanoparticles are prepared by the following steps:

[0045] S1. Put 0.15g 2,6-diaminopyridine into the reactor, add 300ml deionized water, seal the reactor, stir and dissolve, add 0.25g formalin after the 2,6-diaminopyridine dissolves, Continue to seal the reactor, stir at 25°C for 30min, put it into an autoclave and react at 120°C for 16h to obtain the mixed material;

[0046] S2. After centrifuging the mixed material, pour off the supernatant, wash twice with water, wash once with methanol, use a Soxhlet extractor to purify with methanol fo...

Embodiment 3

[0048] A size-controllable Schiff base polymer nanoparticle is prepared by reacting 2,6-diaminopyridine and formalin through a Schiff base; wherein, the content of formaldehyde in 2,6-diaminopyridine and formalin The molar ratio is 1:2; the particle size of the size-controllable Schiff base polymer nanoparticles is 150nm; the concentration of formaldehyde in formalin is 40wt%

[0049] The size-controllable Schiff base polymer nanoparticles are prepared by the following steps:

[0050] S1. Put 0.15g of 2,6-diaminopyridine into the reactor, add 300ml of deionized water, seal the reactor, stir and dissolve, add 0.206g of formalin after the 2,6-diaminopyridine is dissolved, and continue Seal the reactor, stir at 25°C for 1h, put it into an autoclave and react at 60°C for 18h to obtain the mixed material;

[0051] S2. Centrifuge the mixed material, discard the supernatant, wash twice with water, wash once with methanol, purify with methanol for 72 hours using a Soxhlet extractor, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com