Laser cladding rolling composite machining technology and device

A technology of laser cladding and composite processing, which is applied in the direction of metal material coating process, manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as cracks, residual tensile stress of laser cladding layer, coarse grains, etc., and achieve reduction Expansion rate, production efficiency, environmental protection, and fatigue life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

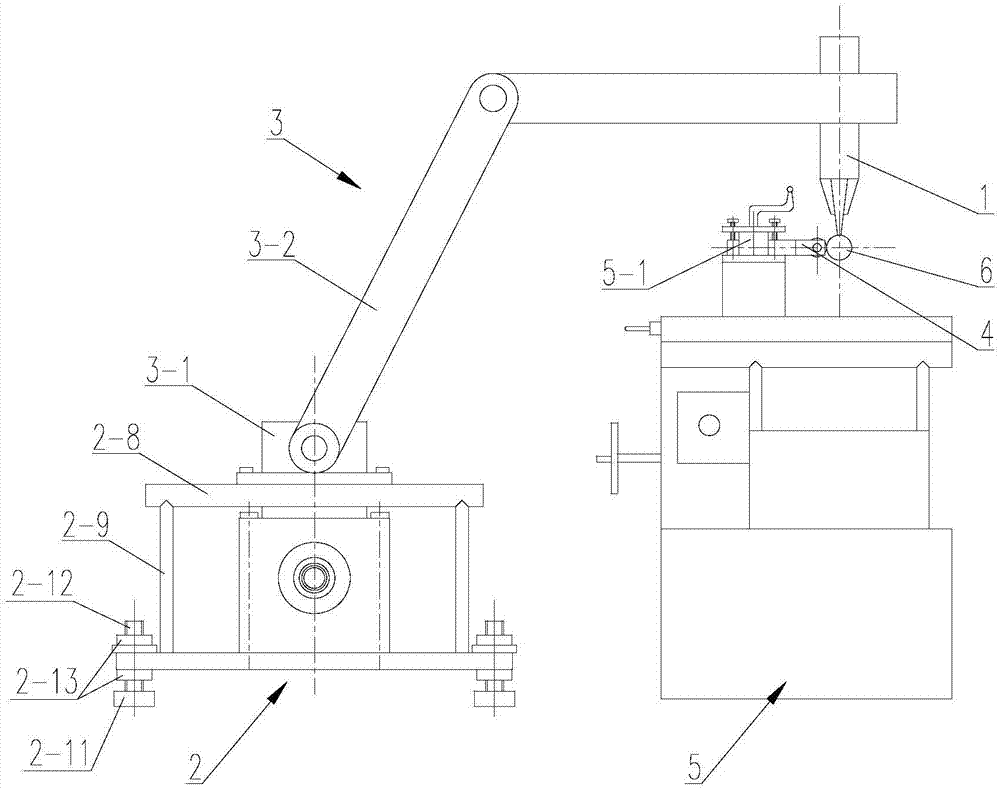

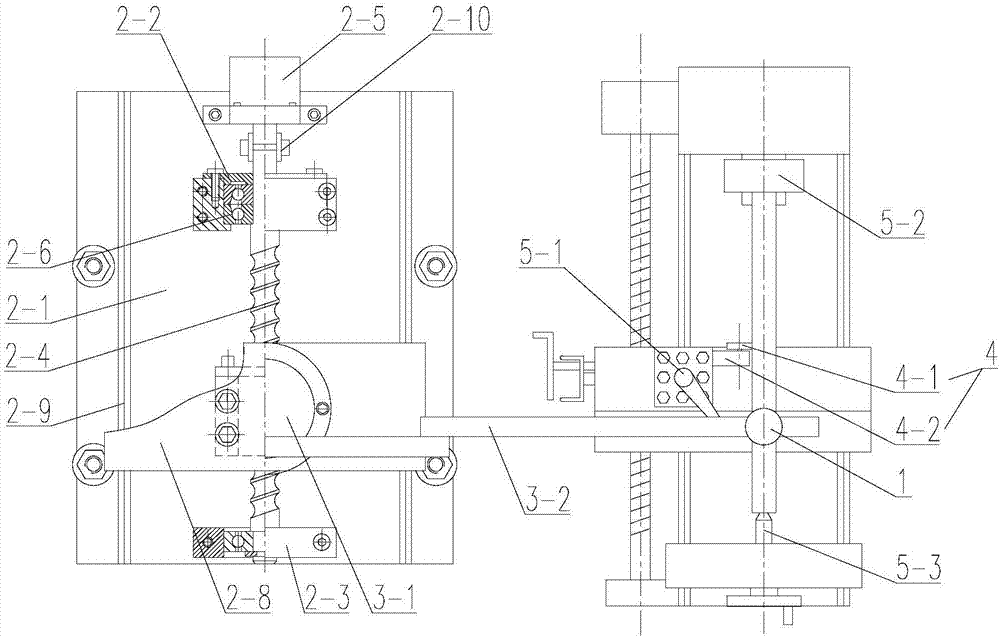

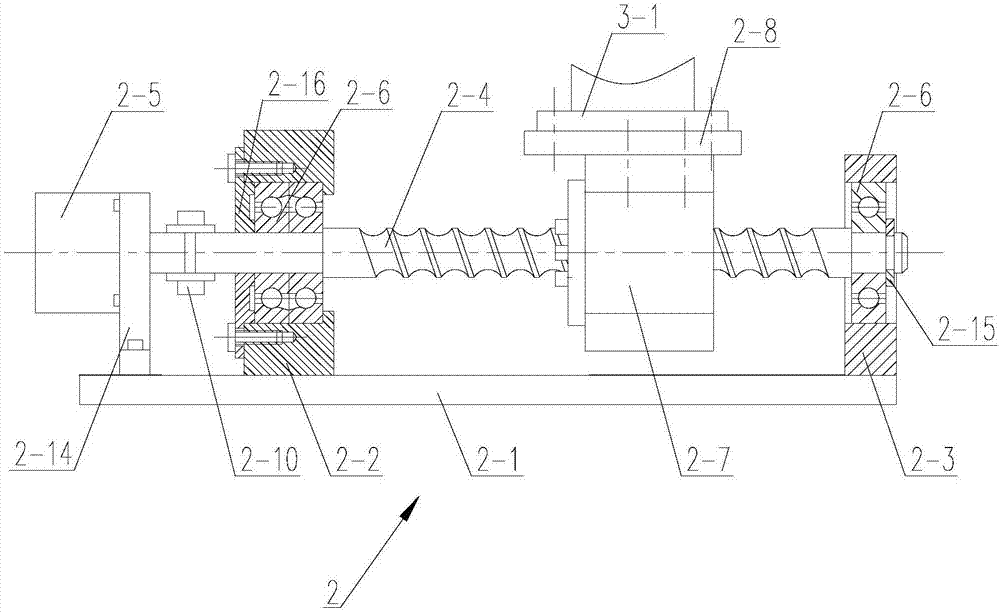

[0041] Such as Figure 1-3 As shown, a laser cladding and rolling composite processing device is used for cladding the cladding part 6 to form a cladding layer and rolling the cladding layer. The device includes:

[0042] Laser cladding head 1, the laser cladding head 1 is used to conduct the laser beam;

[0043] The robot, the robot includes a sliding system 2 and a manipulator 3 arranged on the sliding system 2, the sliding system 2 is used to drive the manipulator 3 to move along a straight line, and the laser cladding head 1 is clamped on the manipulator 3;

[0044] The outer circular rolling knife 4 is used to apply radial pressure to the cladding layer;

[0045] And the horizontal lathe 5, the outer circular rolling knife 4 is fixed on the tool rest 5-1 of the horizontal lathe 5, and the three-jaw chuck 5-2 of the horizontal lathe 5 is clamped on one end of the cladding part 6, and the horizontal The tip 5-3 of the lathe 5 touches the other end of the cladding part 6, ...

Embodiment 2

[0065] A laser cladding and rolling composite processing process, the process is: the laser beam transmitted by the laser cladding head 1 is irradiated on the surface of the cladding part 6, the cladding part 6 rotates, and the laser cladding head 1 moves along the cladding part 6 Move axially to form a cladding layer on the surface of the cladding part 6. At the same time, the outer cylindrical rolling knife 4 applies a certain pressure to the cladding layer along the radial direction of the cladding part 6 under the action of an external force to obtain a modified cladding layer. Rolling is performed while cladding, and the outer peripheral surface of the cladding part 6 is a peripheral surface.

[0066] The process specifically includes the following steps:

[0067] a. The cladding part 6 is polished, cleaned and dried in sequence;

[0068] b. Then use the three-jaw chuck 5-2 and the top 5-3 of the horizontal lathe 5 to clamp the dried cladding part 6;

[0069] c. The las...

Embodiment 3

[0072] Taking the laser cladding of aluminum alloy shaft as an example, the above-mentioned laser cladding-rolling composite processing technology is explained:

[0073] First use sandpaper to polish the φ30×300mm ZL104 aluminum rod, then degrease it with acetone, then dry it with hot air, install the pretreated ZL104 aluminum rod on the CNC lathe CK6140, use three-jaw chuck 5-2 and top 5 -3 clamping, the outer circular rolling knife 4 adopts hard alloy single-roller outer diameter roller rolling knife, the radial pressing amount of the outer cylindrical rolling knife 4 is 0.03mm, and the laser cladding head 1 is along the aluminum alloy shaft The axial feed rate is 0.3mm / r, and the speed of the CNC lathe spindle is 7.64r / min;

[0074] The laser cladding powder is ZL104 aluminum alloy spherical powder with a particle size of 75-150 μm. Before cladding, the aluminum alloy powder must be dried under vacuum conditions at about 120°C to remove the moisture in the cladding powder; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com