Antifouling coating composition, antifouling coating film, substrate having antifouling coating film, antifouling substrate, method for producing substrate having antifouling coating film, and method for preventing fouling of substrate

An antifouling paint, composition technology, applied in the direction of antifouling method, antifouling/underwater paint, cleaning method and utensils, etc., can solve the problem of increased ship surface roughness, shortened substrate life, substrate strength and function Reduction and other problems, to achieve the effects of excellent coating consumption, excellent antifouling, and excellent physical properties of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0147] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples. Hereinafter, "parts" refer to parts by weight as long as the idea is not violated.

[0148]

[0149] In the present invention, the solid content refers to the heating residue after drying a mixture / composition containing a solvent and the like in a hot air dryer at 105° C. for three hours to volatilize the solvent and the like.

[0150]

[0151] The Mn and Mw of the polymers obtained below were measured with "HLC-8120GPC" manufactured by Tosoh Corporation, using two "TSK-gelα type" separation chromatography columns (α-M) manufactured by Tosoh Corporation, 20 mM Dimethylformamide (DMF) to which LiBr was added was used as an eluent, and measurement was performed by gel permeation chromatography (GPC). These Mn and Mw were calculated|required as polystyrene conversion value.

[0152]

[0153] The Gardner viscosity of the polymer obtained below w...

manufacture example 1

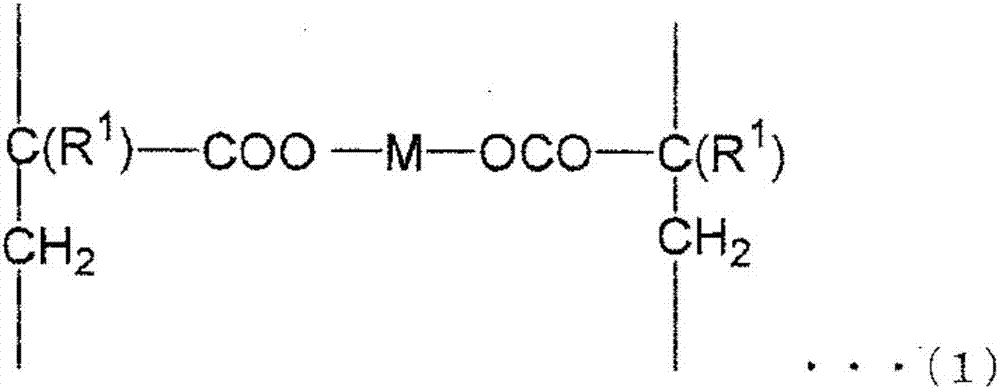

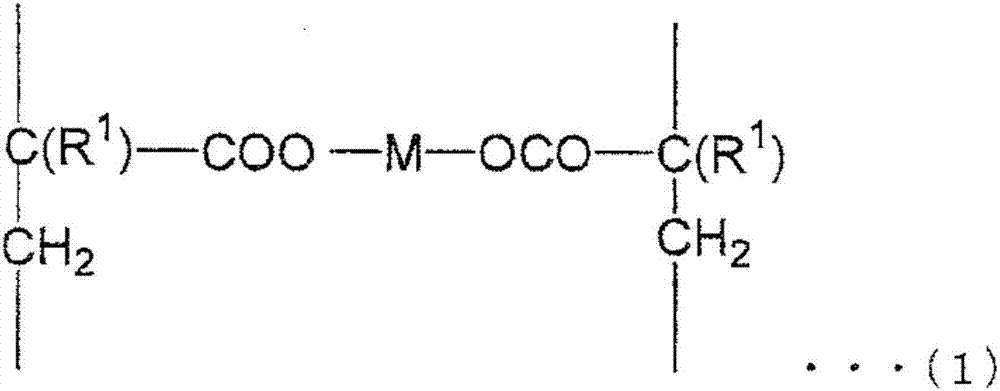

[0158] [Production example 1] Production of hydrolyzable copolymer composition (A1-1-1)

[0159] Add 10 parts of PGM, 35 parts of xylene and 4 parts of ethyl acrylate to an autoclave capable of pressurized polymerization equipped with a cooler, a thermometer, a drip tank and a stirrer, and pressurize to 350kPa while stirring and raise the temperature to 135 ℃. Then, through the drip tank, add dropwise the polymerizable monomer mixture (a1-1) consisting of 15 parts of methyl methacrylate, 48 parts of ethyl acrylate, 15 parts of n-butyl acrylate, and 40 parts of metal atoms at a constant speed for 2.5 hours. , 10 parts of xylene, 1.8 parts of chain transfer agent (NOFMA MSD manufactured by NOF Corporation (NOF (KK)), 4 parts of 2,2'-azobisisobutyronitrile (AIBN) and 2 parts of 2, Clear mixture of 2'-azobis(2-methylbutyronitrile) (AMBN). After completion of the dropwise addition, the temperature was lowered to 110° C. over 30 minutes, and 0.5 parts of tert-butylperoxyoctanoate ...

manufacture example 2

[0161] [Production example 2] Production of hydrolyzable copolymer composition (A1-1-2)

[0162] Add 10 parts of PGM, 37 parts of xylene and 4 parts of ethyl acrylate into a four-necked flask equipped with a cooler, a thermometer, a dropping funnel and a stirrer, and heat up to 100°C while stirring. Then, through the dropping funnel, add dropwise the polymerizable monomer mixture (a1-1) consisting of 15 parts of methyl methacrylate, 52 parts of ethyl acrylate, 8 parts of n-butyl acrylate, and 47 parts of metal atoms at a constant speed for 2.5 hours. , 10 parts of xylene, 2 parts of chain transfer agent (NOFMA MSD manufactured by NOF Corporation), 3 parts of AIBN, and 8 parts of AMBN. After completion of the dropwise addition, 0.5 parts of tert-butyl peroxyoctanoate and 7 parts of xylene were added dropwise over 30 minutes, and after further stirring for 1 hour and 30 minutes, 3 parts of xylene were added. By filtering the resulting mixture through a 300-mesh sieve, a light y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com