Method for preparing non-sintered ceramic preform composite materials

A technology of composite materials and prefabricated bodies, which is applied in the field of ceramic composite materials, can solve problems such as inability to combine molten metal, complex preparation process, and limitations, and achieve the effects of improving interaction, simple process flow, and improving bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

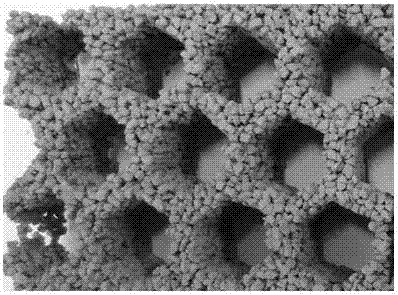

[0027] Embodiment 1: as figure 1 and figure 2 Shown, a kind of preparation method of ZTA ceramic particles reinforced high-chromium cast iron-based honeycomb composite material, the specific steps are as follows:

[0028] (1) Weigh irregularly shaped zirconia-toughened alumina (ZTA) ceramic particles, in which the particle size of the ceramic particles is 10-12 meshes, and weigh silicon carbide ceramic powder, in which the quality of the ceramic powder is zirconia-toughened 8% of the mass of alumina (ZTA) ceramic particles, uniformly mix ceramic powder and binder to obtain mixture A, wherein the binder is silica sol, and the mass ratio of binder to ceramic powder is 1:4;

[0029] (2) Add the zirconia toughened alumina (ZTA) ceramic particles in step (1) to the mixture A obtained in step (1) and mix evenly to form a layer on the surface of the zirconia toughened alumina (ZTA) ceramic particles The coating layer of ceramic micropowder is then evenly filled into the honeycomb ...

Embodiment 2

[0033] Embodiment 2: as figure 1 and figure 2 Shown, a kind of preparation method of ZTA ceramic particles reinforced high manganese steel matrix honeycomb composite material, concrete steps are as follows:

[0034] (1) Weigh irregularly shaped zirconia-toughened alumina (ZTA) ceramic particles, in which the particle size of the ceramic particles is 90-120 mesh, and weigh boron carbide ceramic powder, in which the quality of the ceramic powder is zirconia-toughened 10% of the mass of alumina (ZTA) ceramic particles, uniformly mix ceramic powder and binder to obtain mixture A, wherein the binder is silica sol, and the mass ratio of binder to ceramic powder is 1:8;

[0035] (2) Add the zirconia toughened alumina (ZTA) ceramic particles in step (1) to the mixture A obtained in step (1) and mix evenly to form a layer on the surface of the zirconia toughened alumina (ZTA) ceramic particles The coating layer of ceramic micropowder is then evenly filled into the honeycomb mold cav...

Embodiment 3

[0039] Embodiment 3: as figure 1 and figure 2 Shown, a kind of preparation method of SiC reinforced aluminum matrix composite material, concrete steps are as follows:

[0040] (1) Weigh the irregularly shaped SiC ceramic particles, wherein the particle size of the ceramic particles is 120-150 mesh, weigh the alumina ceramic powder, wherein the quality of the ceramic powder is 5% of the mass of the SiC ceramic particles, and mix the ceramic powder with The binder is mixed evenly to obtain mixture A, wherein the binder is cellulose (PVA), and the mass ratio of binder to ceramic micropowder is 1:15;

[0041] (2) Add the SiC ceramic particles in step (1) to the mixture A obtained in step (1) and mix evenly, so that a layer of coating layer of ceramic micropowder is formed on the surface of the SiC ceramic particles, and then evenly filled into the mold cavity to prepare The prefabricated body with a layered structure, the preformed body is placed in a microwave oven for dehydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com