Carbon quantum dot modified lanthanum ferrite/attapulgite nanocomposite material and preparation method and application thereof

A nano-composite material and carbon quantum dot technology are applied in the field of lanthanum ferrite/attapulgite nano-composite materials and their preparation, which can solve the problems of low low temperature activity and high energy consumption, reduce energy consumption, promote absorption, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

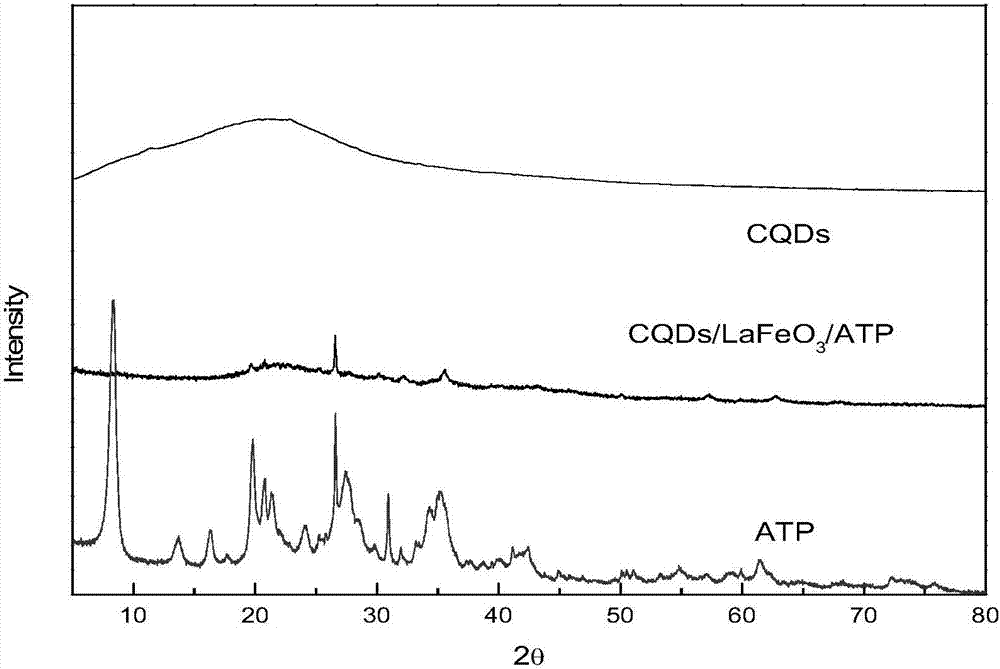

[0022] Preparation of carbon quantum dots:

[0023] Weigh 0.53g of citric acid and dissolve it in 20ml of hydrogen peroxide with a hydrogen peroxide concentration of 0.055mol / L, and ultrasonically dissolve it for 10min to obtain a colorless solution; React for 8 hours; after the reaction, take out the reaction kettle, centrifuge the obtained solution first, then transfer it to a dialysis bag (MWCO = 1000) for secondary water dialysis for 12 hours, and finally transfer it to a vacuum oven at 70°C for drying to obtain carbon quantum dot particles CQDs;

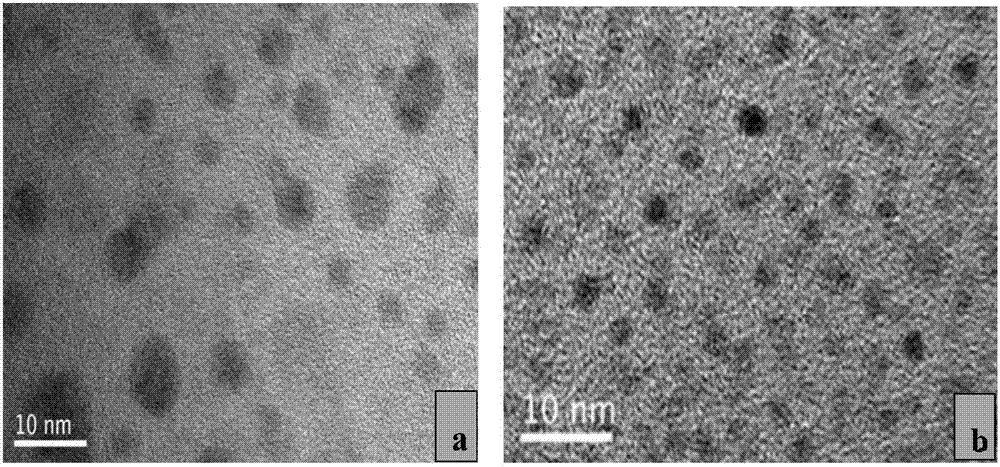

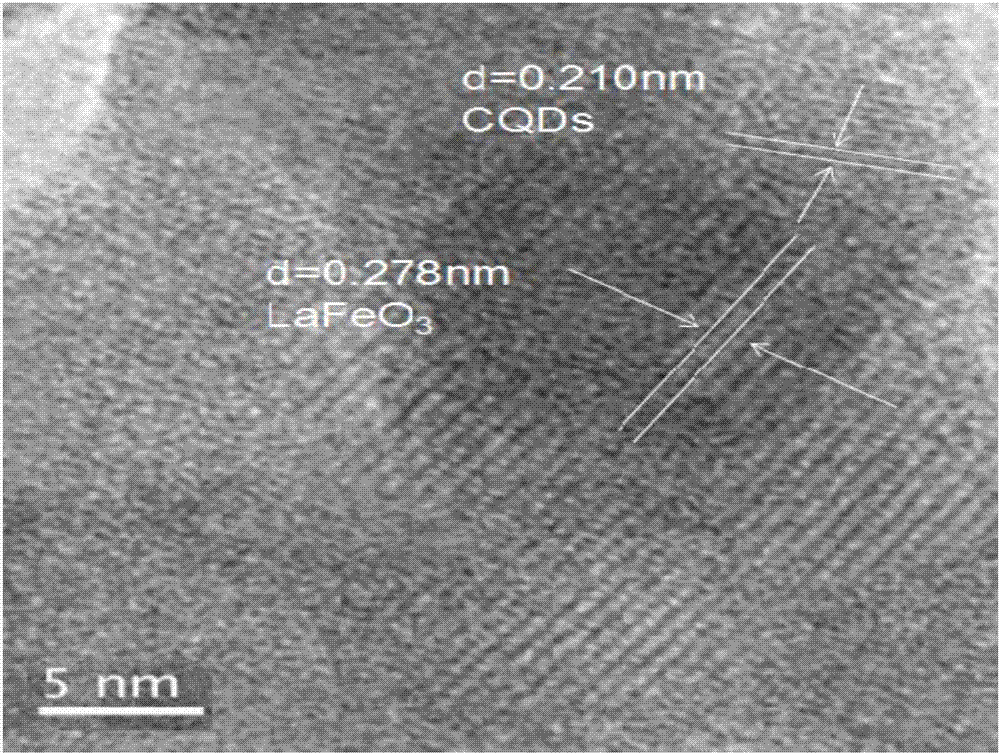

[0024] (1) Add 0.4012g of lanthanum nitrate, 0.4988g of ferric nitrate, 0.5g of citric acid and 1g of attapulgite into 100ml of deionized water and stir well, then transfer to a water bath, evaporate at 60°C for 18h to obtain a wet gel, 80°C After drying, calcinate at 600°C (heating rate: 1°C / min) for 2 hours, and grind to obtain LaFeO 3 / ATP nanocomposites;

[0025] (2) 0.03g of the carbon quantum dot particles prepared abov...

Embodiment 2

[0040](1) with embodiment 1;

[0041] (2) 0.01g of carbon quantum dot particles prepared in Example 1 is dissolved in 20ml of deionized water to obtain a carbon quantum dot solution, and the LaFeO obtained in step (1) is taken 3 Immerse 1 g of the ATP nanocomposite material in the carbon quantum dot solution at room temperature (25° C.) for 24 hours, dry at 100° C. and then grind to obtain a carbon quantum dot-modified lanthanum ferrite / attapulgite nanocomposite material.

Embodiment 3

[0043] (1) with embodiment 1;

[0044] (2) 0.02g of carbon quantum dot particles prepared in Example 1 is dissolved in 20ml of deionized water to obtain a carbon quantum dot solution, and the LaFeO obtained in step (1) is taken 3 Immerse 1 g of ATP nanocomposite material in the carbon quantum dot solution at room temperature (25° C.) for 20 h, dry at 80° C. and grind to obtain carbon quantum dot-modified lanthanum ferrite / attapulgite nanocomposite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com