Explosive cladding method for groove type hot melt interface of metal plate and explosive device

A metal plate and metal plate technology, applied in metal processing equipment, non-electric welding equipment, welding equipment, etc., can solve problems such as the method of recombination explosion at the groove-shaped hot-melt interface that has not been checked, and achieve the effect of saving explosives and recombining Good, low explosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

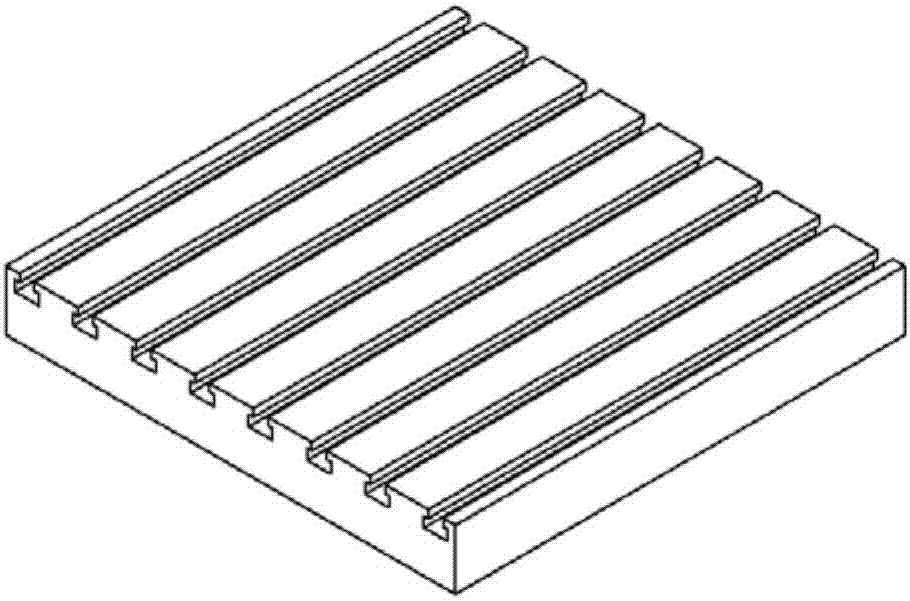

[0044] The cladding and base plate are made of aluminum and carbon steel respectively. Carbon steel is used as the base plate. The size of carbon steel is 200mm×100mm×30mm. I-shaped grooves are opened every 3mm on the surface. The length of the I-shaped groove is 4mm, the width is 2mm, and the opening is 2mm. 2mm, such as figure 1 As shown, the raw material aluminum block used for the cladding plate is melted in a high-temperature furnace, taken out, evenly cast on a carbon steel plate, and cooled to form a cladding plate. Bonded explosives are used for metal plate compounding, the ratio of RDX and nitrocellulose is 95:5, covered with aluminum plate, the schematic diagram of the experimental device is as follows Figure 5 shown. Experimental steps: (1) Use sandpaper to polish the front and back of the substrate 8 and its surroundings to make the surface of the metal plate smooth and smooth, and then use alcohol to clean the surface to be bonded. (2) Remove impurities from th...

Embodiment 2

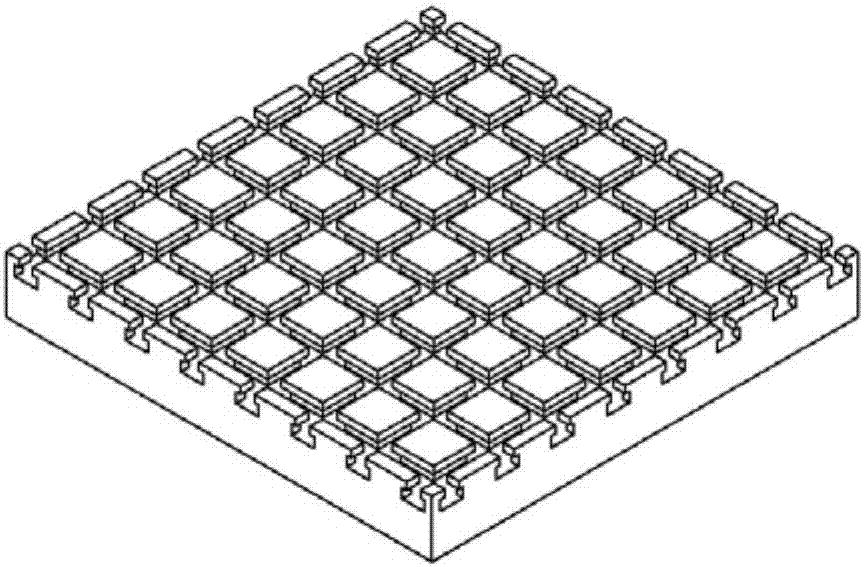

[0046] In this experiment, aluminum and SUS304 stainless steel plates were selected as the cladding plate and substrate of the metal plate composite. The size of the stainless steel was 200mm×150mm×20mm, and criss-cross I-shaped grooves were opened every 3mm on the surface of the substrate. The length of the I-shaped groove is 4mm, the width is 2mm, the opening is 2mm, and the distance from the border is 2mm, such as figure 2 shown. As shown, the raw material aluminum block used for the cladding board is melted in a high-temperature furnace, poured evenly on the stainless steel plate, and cooled to form the cladding board. The size of the bonded explosive is equivalent to the length and width of the base plate and the cladding plate, and the height is 1mm. The schematic diagram of the experimental device is as Figure 5 shown. Experimental steps: (1) Use sandpaper to polish the front, back and surroundings of the substrate 8 to make the surface of the metal plate smooth an...

Embodiment 3

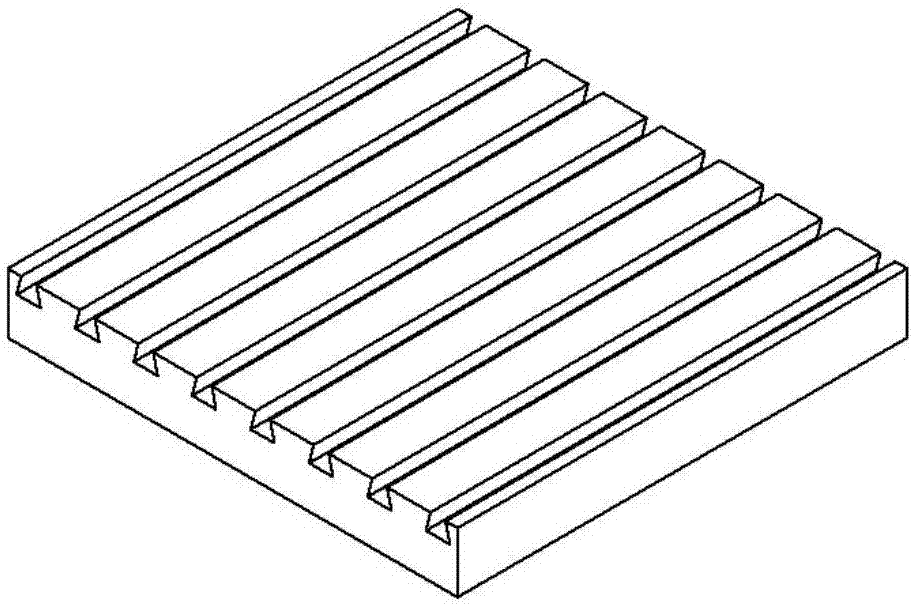

[0048] In this experiment, copper and SUS304 stainless steel were used as the cladding and substrate of the metal plate composite, and the size of the substrate was 150mm×150mm×18mm. Every 3mm on the surface of the substrate, dovetail grooves with 2mm upper bottom, 3mm lower bottom, and 1mm high (such as image 3 ). The size of the substrate is determined according to actual needs. The raw material aluminum used for the cladding plate is melted in a high-temperature furnace, taken out and evenly poured on the SUS304 stainless steel plate, and cooled to form a cladding plate. In this experiment, emulsified explosives were used to compound metal plates, and the ratio of emulsified matrix to glass microspheres was 96:4. The upper surface of the emulsion explosive is covered with an aluminum plate with the same size as the base plate and cladding plate to strengthen the restraint and ensure the stable explosion of the explosive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com