Vanadium pentoxide purification method

A technology of vanadium pentoxide and vanadium oxychloride, applied in the field of purifying vanadium pentoxide and preparing high-purity vanadium pentoxide, can solve the problems of insufficient purity of vanadium pentoxide, strong corrosiveness of chlorine gas, difficulty in regeneration, etc. problem, to achieve the effect of less environmental pollution, high purity, and reducing the generation of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A method for purifying vanadium pentoxide, comprising the steps of:

[0064] (1) Chlorination: Mix 17.2 g of industrial-grade vanadium pentoxide with a raw material purity of 96.5% and anhydrous aluminum trichloride in a molar ratio of 1:4, and the reaction temperature is 170°C for 3.5 hours to obtain oxytrichloride Vanadium gas and alumina residue, the vanadyl chloride gas is condensed, and 24.12g of vanadyl chloride liquid is collected;

[0065] (2) Hydrolysis: Hydrolyze 5 mL of vanadium oxychloride in 110 mL of dilute ammonia water (1+2), filter to obtain 5.99 g of ammonium metavanadate and the filtrate, the filtrate is weakly alkaline with a pH of about 8;

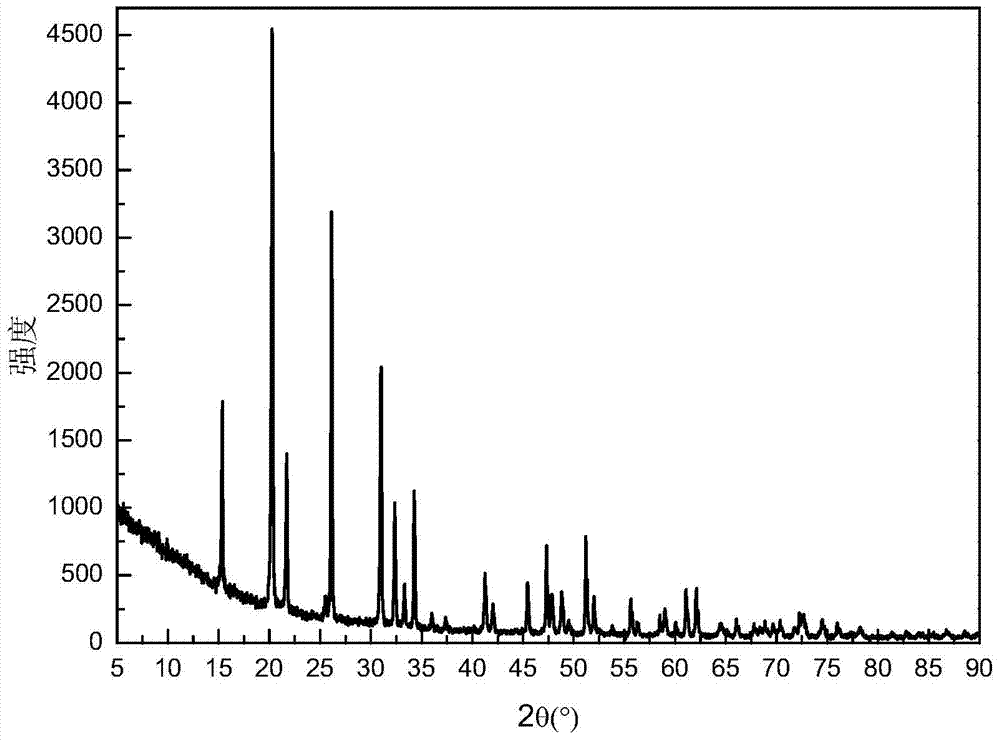

[0066] (3) Pyrolysis: calcining ammonium metavanadate at 500°C for 3 hours in a pure air atmosphere to obtain 4.35 g of an orange-yellow solid product and ammonia gas;

[0067] (4) recovery of by-products: the aluminum oxide residue obtained in step (1) is reacted with hydrochloric acid to reclaim aluminum tric...

Embodiment 2

[0071] A method for purifying vanadium pentoxide, comprising the steps of:

[0072] (1) Chlorination: Mix 17.1 g of industrial-grade vanadium pentoxide with a raw material purity of 97.2% and anhydrous aluminum trichloride at a molar ratio of 1:1, react at a temperature of 160°C, and react for 2 hours to obtain vanadium oxychloride Gas and alumina residue, the vanadyl chloride gas is condensed, and 12.79g of vanadyl chloride liquid is collected;

[0073] (2) Hydrolysis: 5mL of vanadyl trichloride was hydrolyzed in 50mL of high-purity water, and liquid-solid separation obtained 0.17g of polyvanadic acid and filtrate, and the filtrate was strongly acidic with a pH less than 1;

[0074] (3) Pyrolysis: Calcining polyvanadic acid at 500°C for 3 hours in a pure oxygen atmosphere to obtain 0.15 g of orange-yellow vanadium pentoxide product and ammonia gas;

[0075] (4) By-product recovery: the aluminum oxide residue obtained in step (1) is reacted with hydrochloric acid to reclaim a...

Embodiment 3

[0078] A method for purifying vanadium pentoxide, comprising the steps of:

[0079] (1) Chlorination: Mix 18.7g of industrial-grade vanadium pentoxide with a raw material purity of 88.5% and anhydrous aluminum trichloride in a molar ratio of 1:2, and the reaction temperature is 170°C for 3.5 hours to obtain oxytrichloride Vanadium gas and alumina residue, the vanadyl chloride gas is condensed, and 15.45g of vanadyl chloride liquid is collected;

[0080] (2) Hydrolysis: 5mL of vanadyl trichloride is hydrolyzed in 100mL of ammonium chloride (pH is 9) aqueous solution, filters, obtains ammonium polyvanadate 1.04g and filtrate, and filtrate is strongly acidic pH and is 1;

[0081] (3) Pyrolysis: calcining ammonium polyvanadate at 500°C for 3 hours in a pure air atmosphere to obtain 0.92 g of orange-yellow vanadium pentoxide product and ammonia gas;

[0082] (4) By-product recovery: the aluminum oxide residue obtained in step (1) is reacted with hydrochloric acid to reclaim alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com