Composite resin metal mold and manufacturing method thereof

A metal mold and composite resin technology, applied in the field of mold processing, can solve the problems that powder and leftover materials cannot be recycled and reused, cannot be used as casting molds, and dust is difficult to control, so as to solve the problem of processing dust pollution and production cost The effect of low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

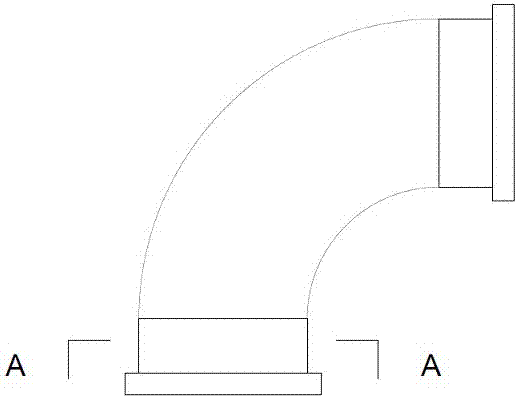

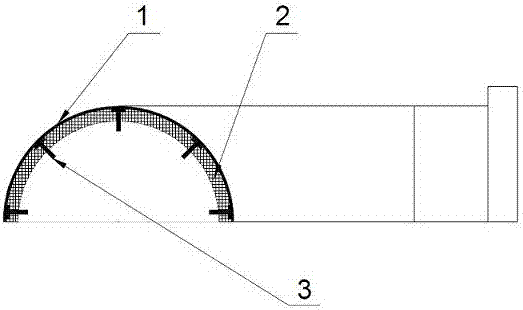

[0022] see figure 1 and figure 2 , the present invention provides a technical solution:

[0023] A composite resin metal mold, the composite resin metal mold includes a metal layer 1, a resin fiber layer 2 and a metal support frame 3, the resin fiber layer 2 is arranged on the back layer of the metal layer 1, and the metal support frame 3 runs through One end of the resin fiber layer 2 is fixedly connected to the inner side of the metal layer 1 , and the other end protrudes from the resin fiber layer 2 .

[0024] In order to further improve the processing efficiency of the metal layer 1, the metal layer 1 is processed by casting, forging and milling integrated metal 3D printing equipment, and the thickness is about 2-3mm. This method solves the dust pollution in the process of traditional mold processing question.

[0025] In order to further improve the stability and strength of the mold, the metal support frame 3 is T-shaped, and the metal support frame 3 and the metal l...

Embodiment 2

[0035] Manufacture a large mold with a length of 8m. Due to the small processing stroke of the 3D printing equipment, the metal layer 1 is decomposed into 4 modules according to the design of the drawing for metal 3D printing processing and molding. On a high-precision flat plate, according to the actual size of the drawing of the mold The shape is lofted and assembled according to the positioning line, and the 4 metal layer modules are combined into a complete large-scale mold metal layer 1, and then the metal layer 1 and the metal support frame 3 are connected through the preset screw holes and / or bolts on the back, and finally the The resin fiber layer 2 is laid on the back layer of the metal layer 1, and the steps are as follows: heat the modified resin to 30°C in a constant temperature box for 50 minutes; spray a thin layer on the back layer of the metal layer 1 with a thickness of 0.1-0.3 mm modified resin, when it is semi-gel, apply the second layer of modified resin qui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com