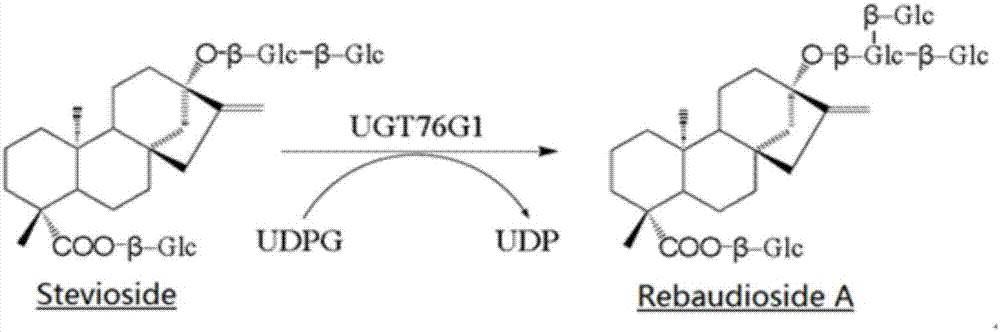

Genetically engineered bacteria and application thereof to preparation of rebaudioside A

A technology of genetically engineered bacteria and engineered bacteria, applied in the field of bioengineering, can solve the problems of low adsorption selectivity of RA glycosides, low yield of rebaudioside A, complicated recrystallization process, etc., so as to improve cell stability and reduce Cell damage, potent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

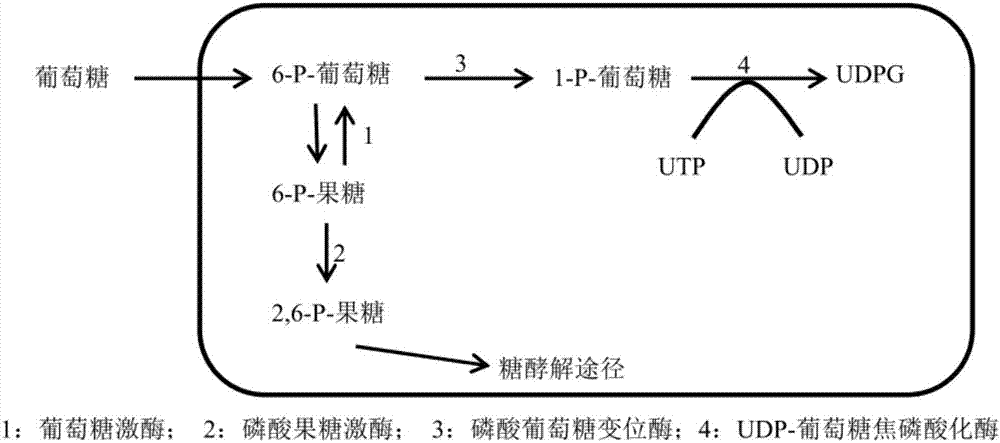

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: Construction of recombinant yeast

[0048] 1. Acquisition of glycosyltransferase UGT gene:

[0049] According to the AY345974.1 gene sequence, the codon optimization was carried out, and the optimized gene sequence was named UGT, and the gene synthesis was completed by Nanjing Jinsirui Company. The sequence is shown in SEQ.NO.2.

[0050] Design primers based on UGT gene sequence

[0051] Upstream primers (-sense containing Sal i) For P1:

[0052] 5'-cactatagggcccgggcgtcgacATGTCTGAAAATAAGACTGAAACT-3'

[0053] Downstream primers (-sense containing xho i) For P2:

[0054] 5'-TCTTAGCTAGCCGCGGTACCAAGCTTACTCGAGTTATAATGATGAAAT-3'

[0055] All primers were synthesized by Shanghai Shenergy Gaming Company.

[0056] Gene PCR conditions (50 uL system):

[0057] PCR system: 50μL

[0058] ddH2O: 19 μL

[0059] P1: 2 μL

[0060] P2: 2 μL

[0061] Template: 2 μL

[0062] 2×Phanta Master Mix: 25μL

[0063] Denaturation at 94°C for 5min, followed by 30 cycles...

Embodiment 2

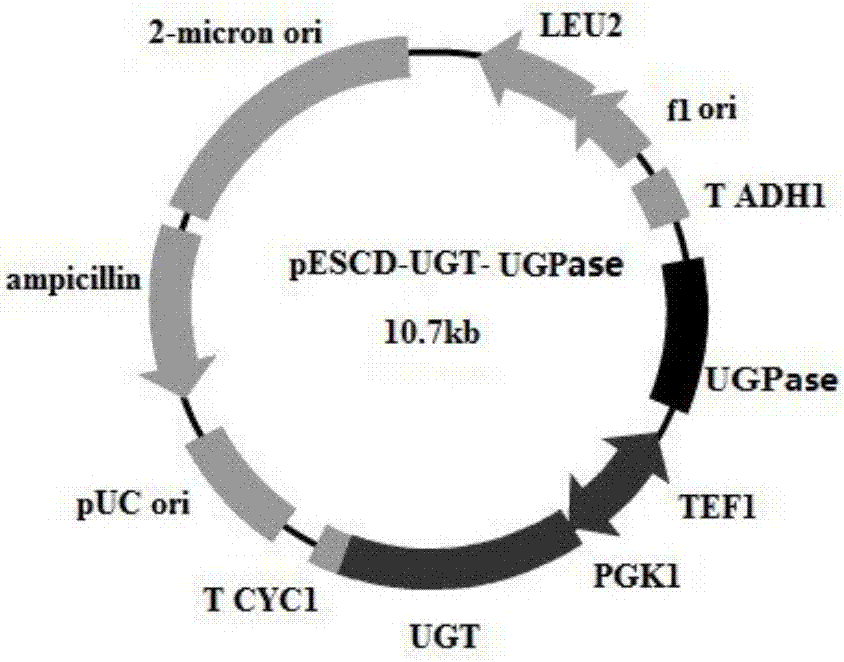

[0085] Example 2: Recombinant Saccharomyces cerevisiae co-express UGT and UGPase

[0086] Activation of strains: In a sterile environment, spread the strains preserved in glycerol tubes on YPDA plates and grow at 30°C for 24-36 hours. Pick a single colony on the YPDA plate and spread it on the SC screening medium in three areas, and grow at 30°C for 24-36 hours.

[0087] Fermentation culture of recombinant bacteria: Pick a single colony on the SC screening plate and transfer it to liquid SC medium, grow at 30°C for 16-20 hours, centrifuge at 6000rpm for 5min, and wash the bacteria twice with potassium phosphate buffer.

[0088] Among them, the nutrient-rich medium YPDA formula is: 10g / L yeast extract, 20g / L peptone, 20g / L glucose, 0.75g / L adenine. Screening medium SC formula is: 6.7 g / L LYNB, 20 g / L glucose, 0.1 g / L adenine, 0.1 g / L cysteine, 0.1 g / L arginine, 0.1 g / L uracil, 0.1g / L Threonine, 0.1g / L Lysine, 0.1g / L Tryptophan, 0.05g / L Histidine, 0.05g / L Aspartic Acid, 0.05g / L ...

Embodiment 3

[0089] Embodiment 3: the establishment of enzyme activity assay method

[0090] The recombinant Saccharomyces cerevisiae cells collected by centrifugation were washed twice with 0.1 mM potassium phosphate buffer (pH 8.0), and the cells were broken by high pressure. Then 4°C, centrifuged at 6000r / min for 30 min to collect the crude enzyme extract for later use.

[0091] Determination of UGT enzyme activity reaction system:

[0092] In a 3 mL reaction system (1.2 mM St glycoside, 4 mM UDPG, 3 mM MgCl 2 , 0.89 mg crude enzyme, pH = 8.0), add the crude enzyme extract to react, after 3 h at room temperature at 30 °C, add water-saturated n-butanol and vortex to terminate the reaction. The supernatant obtained by extraction with n-butanol was analyzed by high performance liquid chromatography (HPLC). Control bacteria were treated in the same way.

[0093] Determination of UGP enzyme activity reaction system:

[0094] Using UGP reversible reaction, its catalyzed reaction generate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com