A method for preparing fertilizer-water solution and slow-release tank from excess sludge

A technology of excess sludge and slow-release tanks, applied in the field of slow-release tanks, can solve the problems of being difficult to remove, use, and cannot be used as aquatic fertilizers, and achieve the effects of low cost, good fertilizer and water effects, high environmental benefits and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

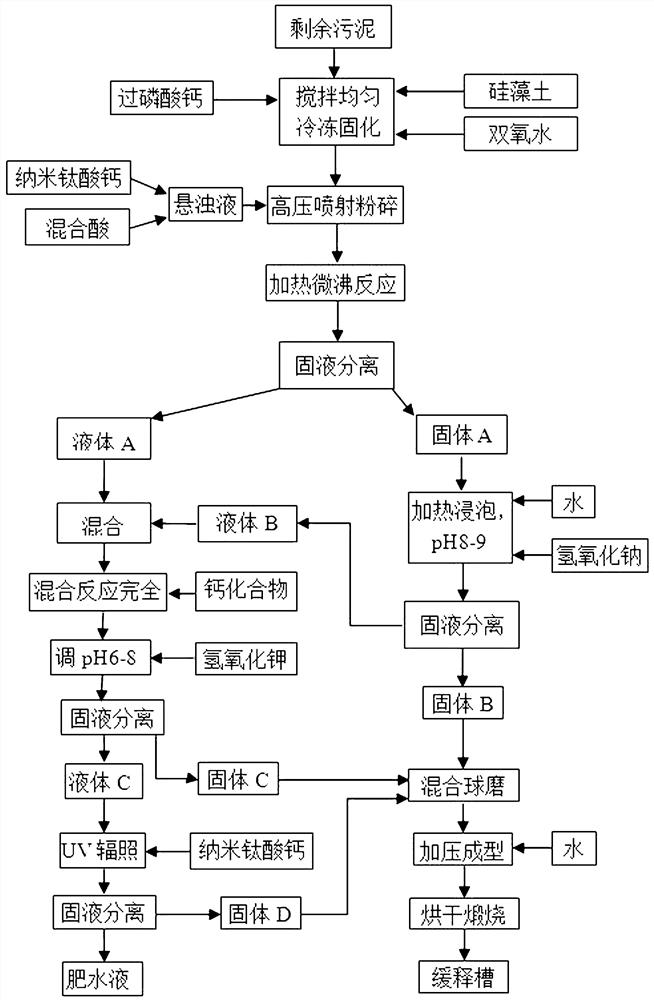

Image

Examples

Embodiment 1

[0021] Embodiment 1: the preparation of fertilizer water slow-release tank 1 and fertilizer water liquid 1

[0022] Take 2Kg of fresh excess sludge with a moisture content of 80%, add 200g of superphosphate, 300g of diatomaceous earth and 400g of 30% hydrogen peroxide, mix well, freeze at -18°C for 24 hours, take it out, To obtain the frozen solid sludge material, take another 2L of mixed acid solution containing 1 mol / L and 0.25 mol / L of nitric acid and sulfuric acid respectively, add 10 g of nano-calcium titanate powder, stir and mix, and disperse evenly to make nano-titanic acid Calcium-mixed acid suspension is heated to 90°C, and the mixed acid suspension is sprayed into the frozen solid sludge at a spray speed of 100m / s with a high-pressure spray gun to crush and melt the frozen sludge , stir evenly, heat and keep boiling slightly for 40min, cool to room temperature, and separate solid and liquid to obtain solid A and liquid A; mix solid A with equal mass of water, stir e...

Embodiment 2

[0023] Embodiment 2: the preparation of fertilizer water slow-release tank 2 and fertilizer water liquid 2

[0024] Take 2Kg of fresh excess sludge with a moisture content of 88%, add 100g of superphosphate, 200g of diatomaceous earth and 200g of 30% hydrogen peroxide, mix well, freeze at -8°C for 24h, take it out, To obtain the frozen solid sludge material, take another 2L of mixed acid solution containing 0.5 mol / L and 0.5 mol / L of nitric acid and sulfuric acid respectively, add 2g of nano-calcium titanate powder, stir and mix, and disperse evenly to make nano-titanic acid Calcium-mixed acid suspension is heated to 60°C, and the mixed acid suspension is sprayed into the frozen solid sludge at a spray speed of 82m / s with a high-pressure spray gun to crush and melt the frozen sludge , stir evenly, heat and keep slightly boiling for 60min, cool to room temperature, and separate solid and liquid to obtain solid A and liquid A; mix solid A with equal mass of water, stir evenly, h...

Embodiment 3

[0025] Embodiment 3: the preparation of fertilizer water slow-release tank 3 and fertilizer water liquid 3

[0026]Take 2Kg of fresh excess sludge with a moisture content of 85%, add 200g of superphosphate, 400g of diatomaceous earth and 400g of 30% hydrogen peroxide, mix well, freeze at -20°C for 24 hours, take out , to obtain frozen solid sludge material, and another 2L of mixed acid solution containing nitric acid and sulfuric acid with 1 mol / L and 0.5 mol / L respectively, was added to 20g of nano-calcium titanate powder, stirred and mixed, dispersed evenly, and made into nano-titanium Calcium acid-mixed acid suspension, heated to 90°C, using a high-pressure spray gun, spray the mixed acid suspension into the frozen solid sludge at a spray speed of 100m / s to crush the frozen sludge Melt, stir evenly, heat and keep boiling slightly for 30min, cool to room temperature, and separate solid and liquid to obtain solid A and liquid A; mix solid A with water of equal mass, stir even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com