A kind of iron-cobalt alloy microstructure catalyst material, preparation method and application

An iron-cobalt alloy, microstructure technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of single synthesis, cumbersome synthesis process and harsh conditions problem, to achieve the effect of high catalytic efficiency, good circulation effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

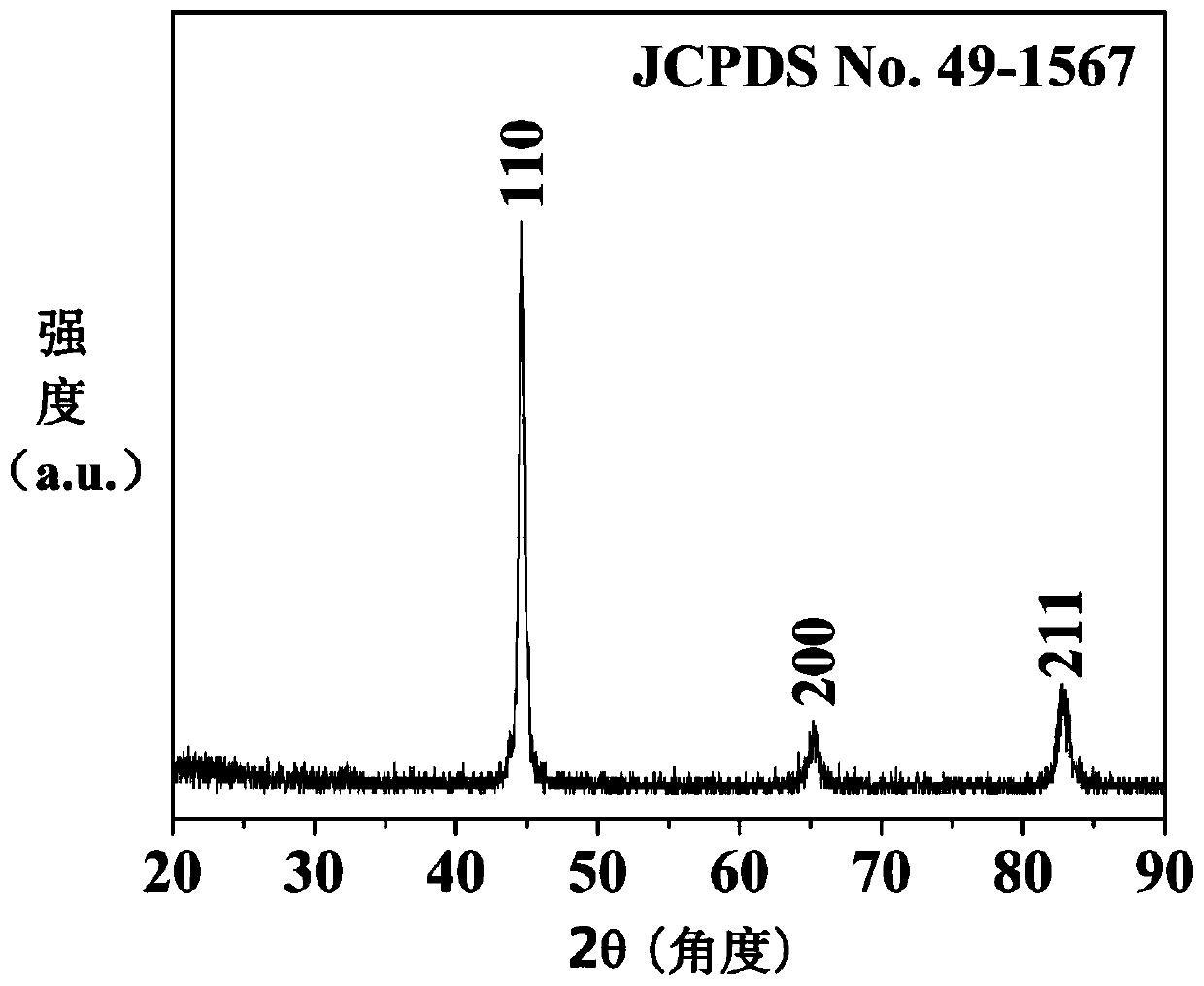

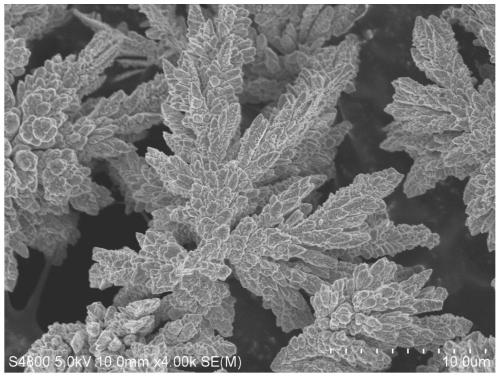

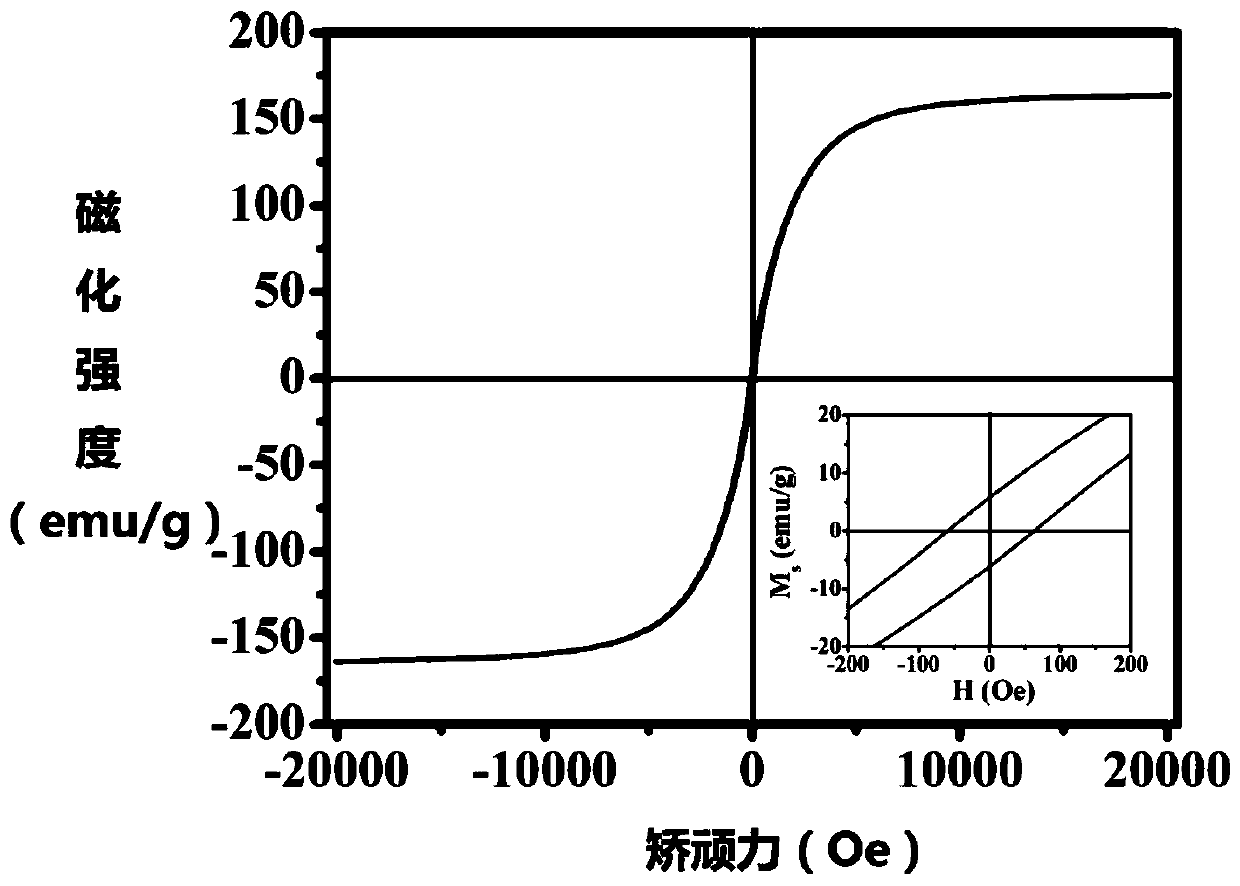

[0044] An iron-cobalt alloy microstructure catalyst material has a three-dimensional wheat spike structure, and the size of the wheat spike structure iron-cobalt alloy material is 4.0-10.0 microns.

[0045] A preparation method for an iron-cobalt alloy microstructure catalyst material, the steps comprising:

[0046]A. Dissolve cobalt chloride hexahydrate and ferric chloride hexahydrate in the mixed solvent formed by ethanol, ethylene glycol and deionized water under stirring to form a uniform solution; wherein the total concentration of metal ions is 0.025 mol / L, the molar ratio of cobalt ion to iron ion is 7:3; the volume ratio of ethanol, ethylene glycol, and deionized water in the mixed solvent is 4:1:0;

[0047] B. Dissolve sodium hydroxide in hydrazine hydrate with a concentration of 85% to form a solution, add it to the above metal salt solution under stirring to form a uniform solution, and then transfer it to polytetrafluoroethylene with a filling degree of 60% In an ...

Embodiment 2

[0053] An iron-cobalt alloy microstructure catalyst material has a three-dimensional wheat ear-like structure, and the size of the wheat ear-shaped iron-cobalt alloy microstructure is 3.0-7.5 microns.

[0054] A preparation method for an iron-cobalt alloy microstructure catalyst material, the steps comprising:

[0055] A. Dissolve cobalt nitrate hexahydrate and ferric nitrate nonahydrate in a mixed solvent formed by methanol, ethylene glycol, and deionized water, and stir fully to form a uniform solution; wherein the total concentration of metal ions is 0.025mol / L, The molar ratio of cobalt ions to iron ions is 6.5:3.5; the volume ratio of methanol, ethylene glycol, and deionized water in the mixed solvent is 4:1:0;

[0056] B. Sodium hydroxide is dissolved in hydrazine hydrate with a mass concentration of 60% to form a solution, which is added to the metal salt solution prepared in step A under stirring to form a uniform solution, and then transferred to a 60% filling In a p...

Embodiment 3

[0059] An iron-cobalt alloy microstructure catalyst material has a three-dimensional wheat ear-like structure, and the size of the wheat ear-shaped iron-cobalt alloy microstructure is 4.0-10 microns.

[0060] A preparation method for an iron-cobalt alloy microstructure catalyst material, the steps comprising:

[0061] A. Dissolve cobalt acetate tetrahydrate and ferrous chloride tetrahydrate in the mixed solvent formed by ethanol, glycerol and deionized water under stirring, and add surfactant PVP to form a uniform solution; The total concentration is 0.05mol / L, the molar ratio of cobalt ion to iron ion is 7:3; the volume ratio of ethanol, glycerol, and deionized water in the mixed solvent is 4:0.5:0.5; the concentration of PVP is 0.05mol / L;

[0062] B. A certain amount of sodium hydroxide is dissolved in hydrazine hydrate with a mass concentration of 80% to form a solution, which is added to the above-mentioned metal salt solution under stirring to form a uniform solution, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com