Fiber hybridized particle and polymer matrix composite material

A technology of hybrid particles and composite materials, which is applied in the fields of magnetic materials, fiber processing, nanotechnology for materials and surface science, etc. The effect of convenient and effective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

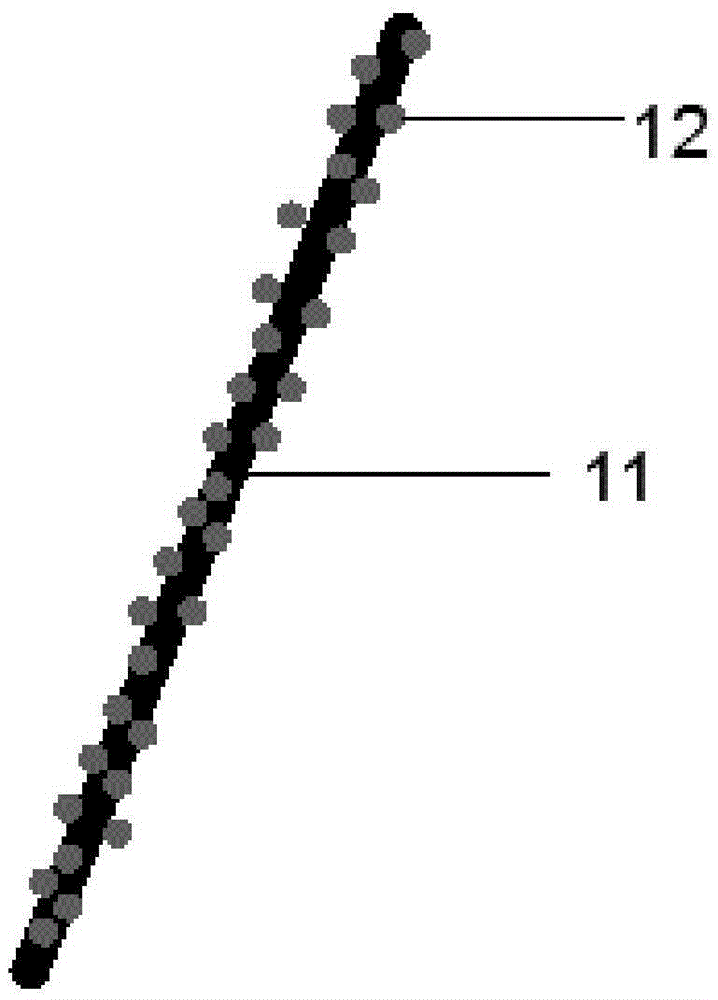

[0048] This embodiment provides a fiber hybrid particle loaded with nano-zinc oxide on the surface of CNT, which is prepared by the following steps:

[0049] Take 1g of carbon nanotube (CNT) and put it into 200mL of concentrated nitric acid and concentrated sulfuric acid (3:1 volume ratio) mixture, and stir at 65°C for 4 hours;

[0050] After the mixture is cooled, dilute it with deionized water, pour off the supernatant after the carbon nanotubes sink, and then dilute it several times to become neutral and then dry it to obtain acidified CNTs;

[0051] Disperse the acidified CNTs into 300mL of ZnO sol, and treat it by ball milling for 12 hours, then put the solution into a three-necked flask and slowly heat it to 180°C for 24 hours;

[0052] After cooling to room temperature, washing with absolute ethanol and deionized water several times, and drying at 100°C for at least 12 hours, the CNT-ZnO fiber hybrid particles can be obtained.

[0053] The CNT-ZnO fiber hybrid particle...

Embodiment 2

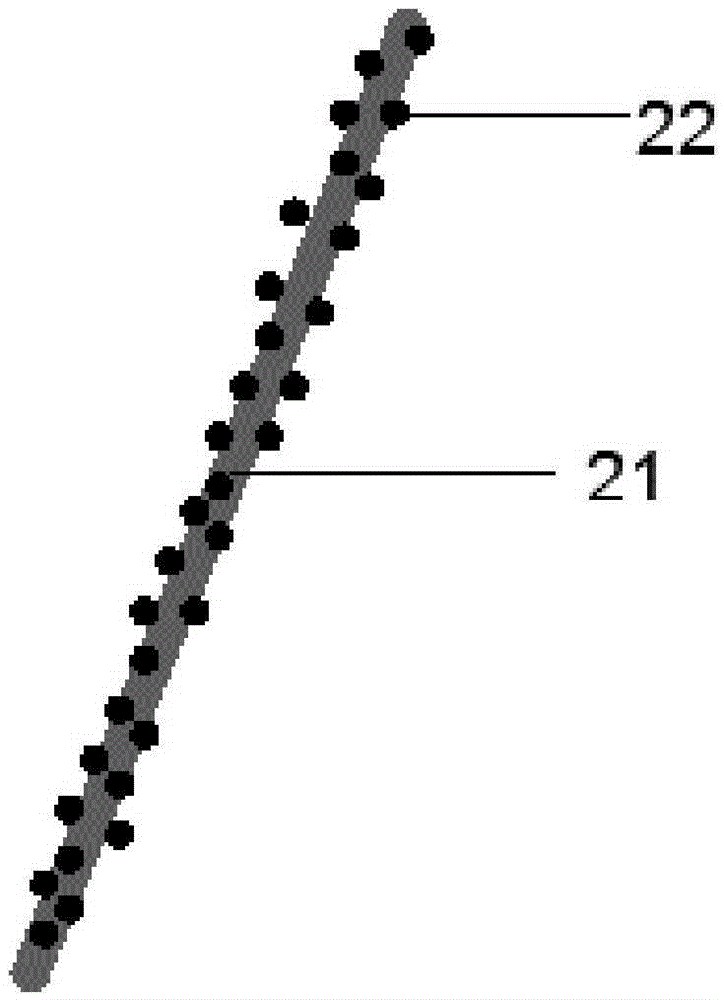

[0056] This embodiment provides a CNT surface loaded BaTiO 3 The fiber hybrid particles, which are prepared by the following steps:

[0057] Disperse 0.25g of CNT into 100mL of absolute ethanol, mix with 0.3mL of 28wt% concentrated ammonia water, and disperse by ultrasonic for 15min;

[0058] Slowly drop 0.75mL of tetrabutyl titanate into the mixture for about 5min, and stir at 45°C for 24h;

[0059] Wash with deionized water and absolute ethanol three times respectively, and dry at 100°C for 12 hours;

[0060] 500℃, sintered in air atmosphere for 2h to CNT-TiO 2 hybrid particles;

[0061] Add CNT-TiO after sintering at 500°C for 2 hours to the aqueous solution of barium source 2 , CNT-BaTiO can be obtained by heating in the reactor at 200°C for 12 hours 3 Fiber hybrid particles.

[0062] The CNT-BaTiO of this embodiment 3 Fiber hybrid particles, untreated CNTs, have no chemical bond with titanium dioxide / barium titanate, relying on the electronegativity difference of e...

Embodiment 3

[0066] This embodiment provides a copper nanowire surface loading TiO 2 Fiber hybrid particles, which are prepared by the following steps:

[0067] Take 0.1M Cu(NO 3 ) 2 Put 10ml, 200ml of 15M NaOH, and 1.5mL of ethylenediamine into a 500mL round bottom flask, heat up to 50°C, and stir at 700rpm;

[0068] After 5min, take 0.25mL of 35wt% N 2 h 4 Quickly added to the above solution;

[0069] After 2 minutes, add 150 mL of an aqueous solution containing 3 wt % polyvinylpyrrolidone (MW = 10000) and 1 wt % diethylhydroxylamine, and react for 1 hour;

[0070] Copper nanowires (CuNW) can be obtained by centrifugation. Finally, CuNW is dispersed in ethanol solution, and 0.5 mL of tetrabutyl titanate is slowly added dropwise, about 5 min, and stirred at 45 ° C for 24 h;

[0071] Washed three times with deionized water and absolute ethanol, dried at 100 °C for 12 h, and then sintered at 500 °C for 2 h in an air atmosphere to form CuNW-TiO 2 Fiber hybrid particles.

[0072] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com