Two-component propeller anti-fouling coating

An anti-fouling paint and propeller technology, applied in anti-fouling/underwater paint, epoxy resin paint, coating, etc., can solve the problems of time-consuming, labor-intensive, fouling, and huge docking fees for manual processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

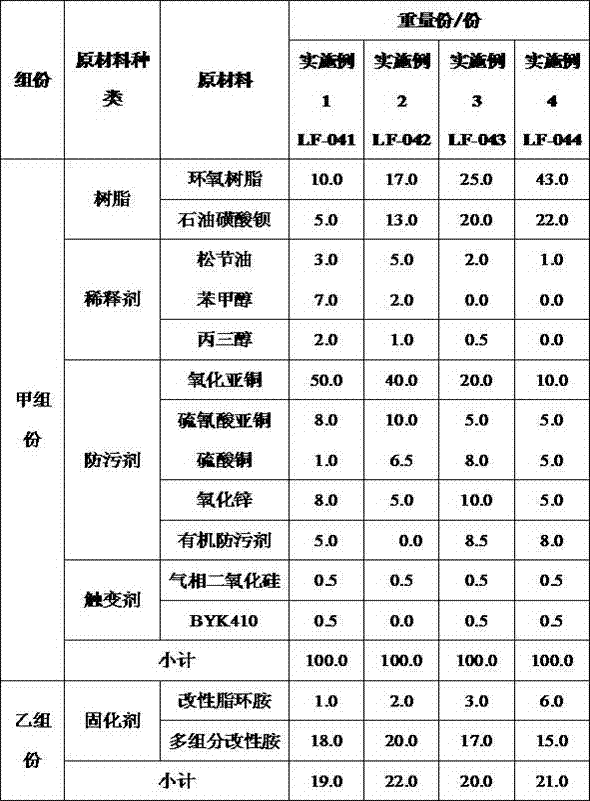

[0034] The composition of A and B components is shown in Tables 1, 2, and 3:

[0035] Table 1 Composition of propeller antifouling coating

[0036]

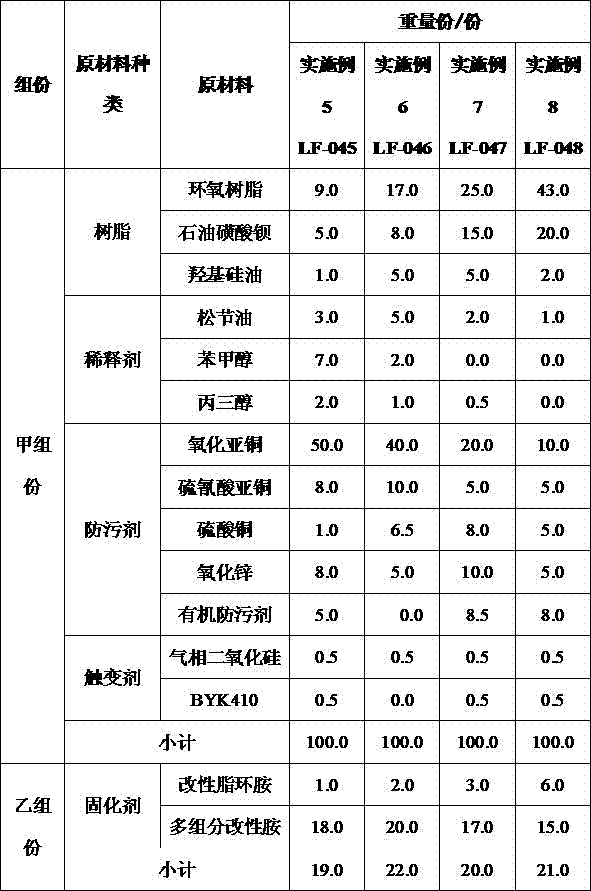

[0037] Table 2 Composition of propeller antifouling coating

[0038]

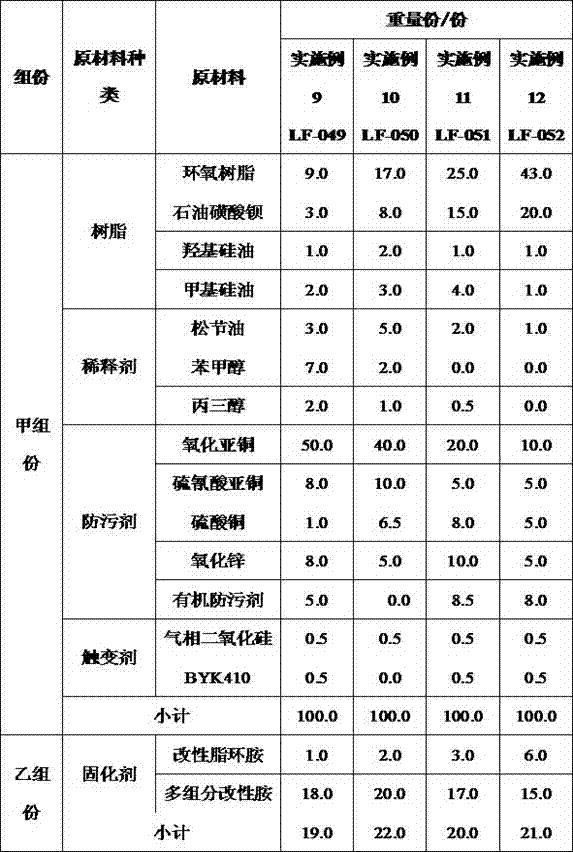

[0039] Table 3 Composition of Propeller Antifouling Paint

[0040]

[0041] The preparation process of component A: first add resin, diluent and thixotropic agent, use high-speed disperser to treat for at least 30 minutes, then add auxiliary antifouling agent and organic antifouling agent, use high-speed disperser to treat for 50-75min, generally take 1 hour The longer the mixing effect, the better, but the longer the time, the longer the waiting time, which is easy to waste time. Use cooling water to cool and add copper antifouling agent, use high-speed disperser for 50-75min, generally use 1h longer mixing time The better the uniform effect, but the longer the waiting time, the longer the waiting time, it is easy to waste time, and the material ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com