Controllable slow-release phase transfer catalyst microcapsules and preparation method of controllable slow-release phase transfer catalyst microcapsules

A technology of phase transfer catalysis and phase transfer catalyst, applied in phase transfer catalysis microcapsules, controlled release phase transfer catalysis microcapsules and the field of preparation thereof, can solve the problem of poor chemical properties and physical stability of phase transfer catalysts, volatile phase transfer catalysts Volatile, phase transfer catalysis reports are not very common, etc., to achieve the effect of good dispersibility, low production cost, and improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

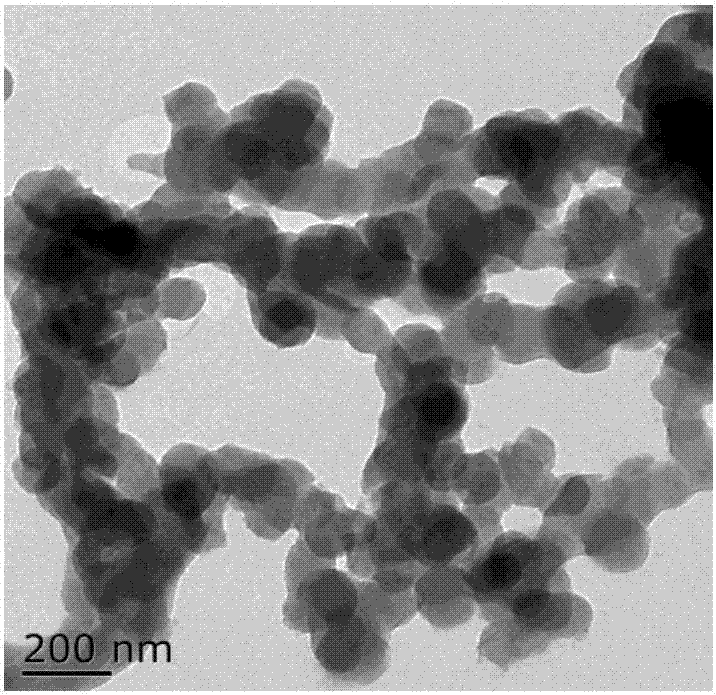

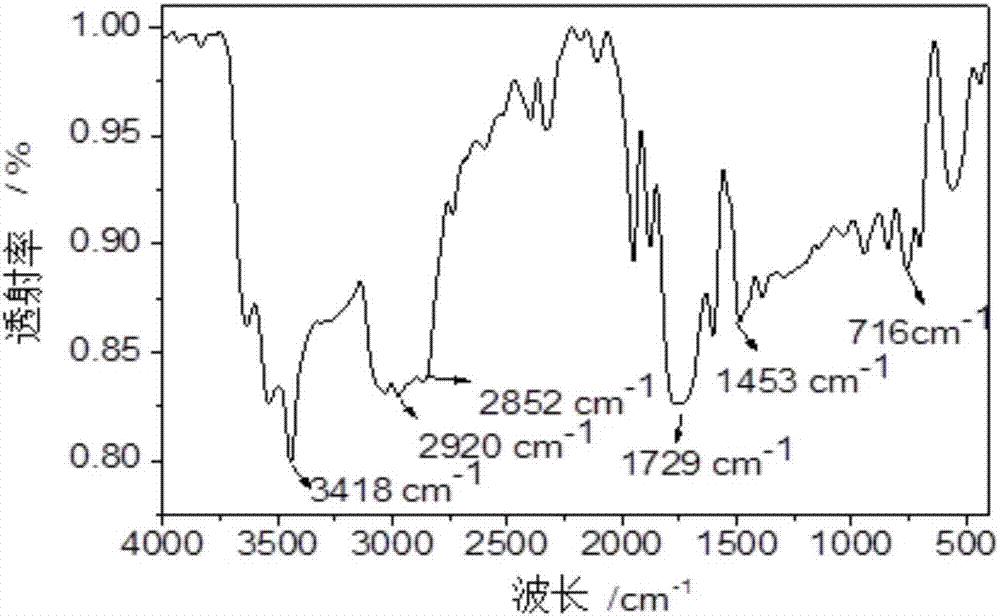

Image

Examples

Embodiment 1

[0042] Embodiment 1: phase transfer catalyst 6.18%, sodium lauryl sulfate 0.31%, polyethylene glycol 6000 0.54%, butanol 2.51%, ethanol 12.19%, potassium persulfate 12.04%, peracetic acid 1.42%, pyrrole 2.99% %, the rest is deionized water, a total of 100%, stirred for 2h.

Embodiment 2

[0043] Embodiment 2: phase transfer catalyst 6.18%, sodium lauryl sulfate 0.31%, polyethylene glycol 6000 0.54%, butanol 2.51%, ethanol 12.19%, potassium persulfate 12.04%, peracetic acid 1.42%, pyrrole 2.99% %, the rest is deionized water, a total of 100%, stirred for 4h.

Embodiment 3

[0044] Embodiment 3: phase transfer catalyst 6.18%, sodium lauryl sulfate 0.31%, polyethylene glycol 6000 0.54%, butanol 2.51%, ethanol 12.19%, potassium persulfate 12.04%, peracetic acid 1.42%, pyrrole 2.99% %, the rest is deionized water, a total of 100%, and stirred for 6h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com