Nickel-based material, preparation method of nickel-based material, and lithium ion battery

A nickel-based, core material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of weak conductivity and large interface transfer resistance, and achieve the effects of good bonding, reducing interface resistance and inhibiting corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The application provides a method for preparing the above-mentioned nickel-based material, comprising the following steps:

[0042] A), mixing oxysilane with an organic solvent, then adjusting the pH value of the obtained solution, and obtaining a coating solution after reaction;

[0043] B), mixing the coating solution with the precursor material shown in formula (II), stirring to obtain SiO 2 The initial nickel-based material for the gel-coated precursor material;

[0044] C), mixing the initial nickel-based material with a lithium salt and performing a high-temperature solid-state reaction to obtain a nickel-based material;

[0045] Ni 1-a-b co a m b (OH) 2 (II);

[0046] Among them, 0≤a<1, 0≤b<1, 0<1-a-b<1;

[0047] M is selected from Mn or Al.

[0048] In the process of preparing nickel-based materials, including the preparation of coating solution, SiO 2 The initial nickel-based material of the gel-coated precursor material and the preparation of the nic...

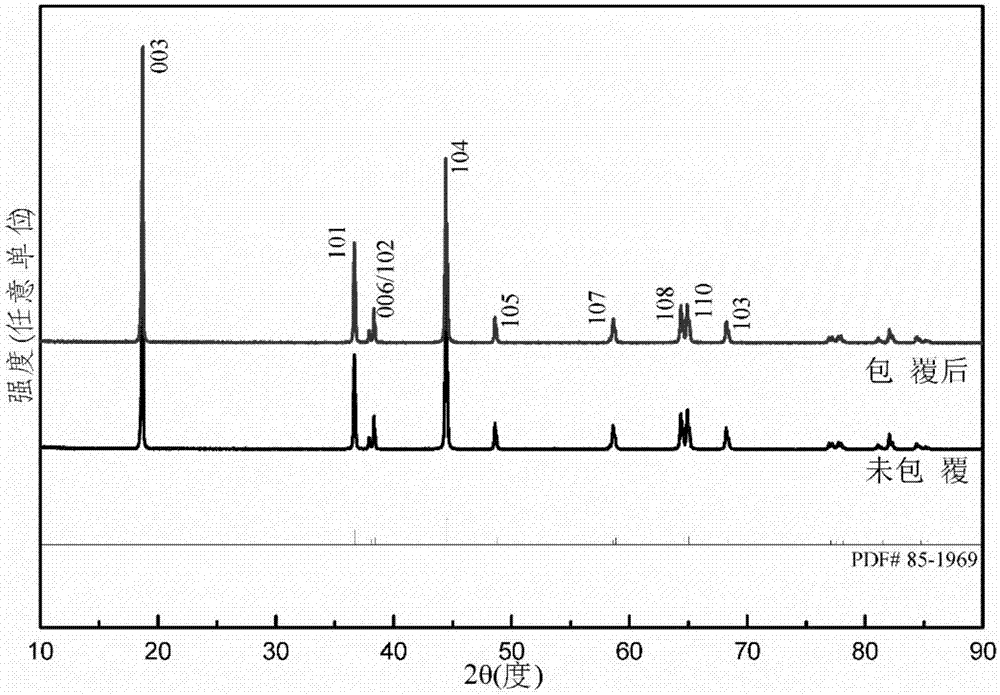

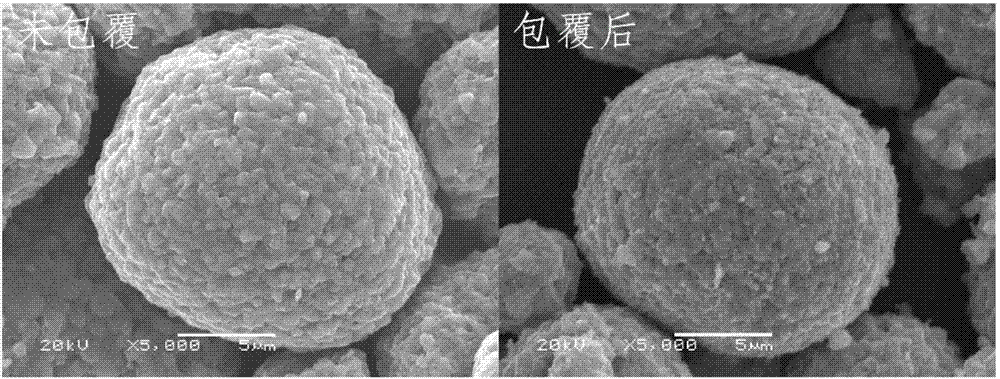

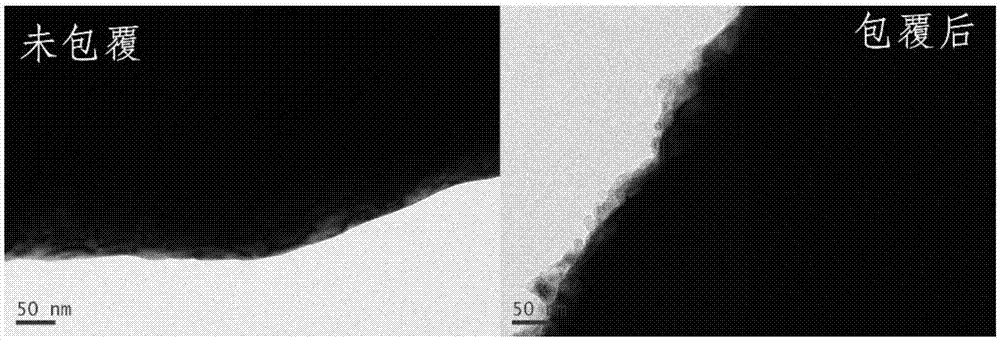

Embodiment 1

[0055] According to the fast lithium-ion conductor phase Li 4 SiO 4 The mass ratio of the coating amount and the nickel-based precursor material is the addition amount of 0.01:1, and 0.37g ethyl orthosilicate is dissolved in the mixed solvent system containing deionized water and ethanol, wherein the volume of deionized water and ethanol The ratio is 2:1, the volume ratio of tetraethyl orthosilicate and mixed solvent is 1:3, the pH value of the system is adjusted to 8.0 with ammonia water, the reaction temperature of the system is controlled at 40°C, and the stirring speed is controlled at 300 rpm. After the silicon salt was hydrolyzed and polycondensed for 1 hour, then ethanol was added to dilute and disperse to obtain 60 g of coating liquid, and milky white micro-dispersed colloidal particles appeared in the coating liquid;

[0056] The commercial nickel-rich precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 Add it into the above coating solution, the mass ratio of the precursor to...

Embodiment 2

[0063] According to the fast lithium-ion conductor phase Li 4 SiO 4 The mass ratio of coating amount and nickel-based precursor material is the addition amount of 0.015:1, and 0.48g methyltriethoxysilane is added in the isopropanol solvent, methyltriethoxysilane and isopropanol The volume ratio of the solvent is 1:4, the pH value of the system is adjusted to 9.0 with ammonia water, the reaction temperature of the control system is 50°C, and the stirring speed is controlled at 400 rpm. Dilute and disperse with ionic water to obtain 80g of coating liquid, which contains milky white micro-dispersed colloidal particles;

[0064] The commercial precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 Add it to the above coating solution, the mass ratio of the positive electrode material precursor to the coating solution is 1:4, keep stirring at a stirring speed of 400 rpm, and after the solvent is volatilized, place it in an oven at 100°C for complete drying. The hydrolyzate nano-scale SiO was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com