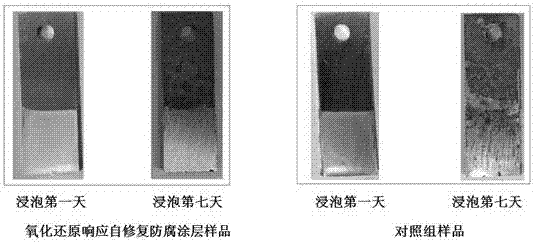

Oxidation-reduction responded self-repairing anticorrosive coating and preparation method thereof

An anti-corrosion coating and self-healing technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of shortening the path and the research on self-healing coatings is still in the blank stage, and achieve the effect of rapid response, good application prospects and sufficient protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of magnetic Fe 3 o 4 / Mesoporous silica nanocontainer

[0036] Dissolve 1.08 g of ferric chloride hexahydrate and 3.65 g of sodium oleate in 8 mL of ethanol, 6 mL of distilled water, and 14 mL of n-hexane, heat the reaction system to 70°C and keep it warm for 4 hours, then separate the upper organic phase, Fully wash with 200 mL of distilled water, then rotatively evaporate the organic phase to remove the n-hexane solvent, add 40 mL of octadecene to the obtained waxy solid, and add 0.886 g of oleic acid, heat to 320 ° C, and keep it warm for 30 minutes. , the product was added to 200mL ethanol, the product was precipitated, and oleic acid-stabilized ferric oxide nanoparticles were obtained.

[0037] Weigh 5 mg of Fe3O4 nanoparticles, dissolve in 2 mL of chloroform, then add this chloroform solution into 50 mL of distilled water, and then add 0.4 g of cetyltrimethylammonium bromide Ammonium bromide and 0.3 mL of 2 mol / L sodium hydroxide solution were vi...

Embodiment 2

[0049] 1. Preparation of magnetic Fe 3 o 4 / Mesoporous silica nanocontainer

[0050] Dissolve 1.08 g of ferric chloride hexahydrate and 3.65 g of sodium oleate in 8 mL of ethanol, 6 mL of distilled water, and 14 mL of n-hexane, heat the reaction system to 70°C and keep it warm for 4 hours, then separate the upper organic phase, Fully wash with 200 mL of distilled water, then rotatively evaporate the organic phase to remove the n-hexane solvent, add 40 mL of octadecene to the obtained waxy solid, and add 0.886 g of oleic acid, heat to 320 ° C, and keep it warm for 30 minutes. , the product was added to 200mL ethanol, the product was precipitated, and oleic acid-stabilized ferric oxide nanoparticles were obtained.

[0051] Weigh 5 mg of Fe3O4 nanoparticles, dissolve in 2 mL of chloroform, then add this chloroform solution into 50 mL of distilled water, and then add 0.4 g of cetyltrimethylammonium bromide Ammonium bromide and 0.3 mL of 2 mol / L sodium hydroxide solution were vi...

Embodiment 3

[0065] 1. Preparation of magnetic Fe 3 o 4 / Mesoporous silica nanocontainer

[0066] Dissolve 1.08 g of ferric chloride hexahydrate and 3.65 g of sodium oleate in 8 mL of ethanol, 6 mL of distilled water, and 14 mL of n-hexane, heat the reaction system to 70°C and keep it warm for 4 hours, then separate the upper organic phase, Fully wash with 200 mL of distilled water, then rotatively evaporate the organic phase to remove the n-hexane solvent, add 40 mL of octadecene to the obtained waxy solid, and add 0.886 g of oleic acid, heat to 320 ° C, and keep it warm for 30 minutes. , the product was added to 200mL ethanol, the product was precipitated, and oleic acid-stabilized ferric oxide nanoparticles were obtained.

[0067] Weigh 5 mg of Fe3O4 nanoparticles, dissolve in 2 mL of chloroform, then add this chloroform solution into 50 mL of distilled water, and then add 0.4 g of cetyltrimethylammonium bromide Ammonium bromide and 0.3 mL of 2 mol / L sodium hydroxide solution were vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com