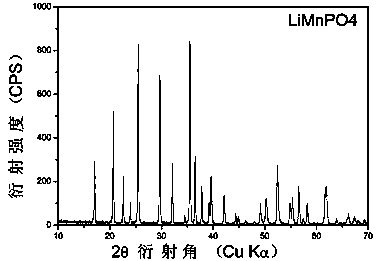

Synthetic method for cathode material nano lithium manganese phosphate for lithium ion batteries

A technology of lithium ion battery and synthesis method, applied in the field of new energy and new materials, can solve the problems of long production cycle, high production cost, pollution, etc., and achieve the effects of saving energy, shortening synthesis time and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

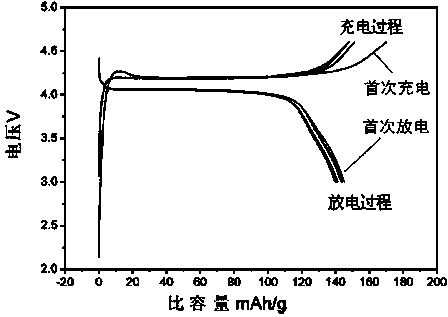

[0034] Battery preparation and electrochemical performance testing method

[0035] (1) Preparation of battery cathode sheet :

[0036] Mix the obtained lithium-ion battery positive electrode material lithium manganese phosphate, conductive carbon powder, and organic binder polyvinylidene fluoride (PVDF) according to a mass ratio of 92:3:5 to obtain a mixed powder. 10 grams of the mixed powder, Add 12 grams of N-methylpyrrolidone (NMP) as an organic solvent, stir well to form a slurry, coat the surface of aluminum foil, dry it, and roll it several times to obtain the positive electrode sheet of the battery;

[0037] (2), battery assembly and performance testing

[0038]The electrochemical performance of obtained lithium manganese phosphate was evaluated using a 2016-type half-cell. The rolled battery pole piece is stamped into a disc with a diameter of 12 mm. After accurately weighing its mass, the mass of lithium manganese phosphate in the pole piece is calculated acco...

Embodiment 1

[0042] A method for synthesizing nano-manganese lithium phosphate as a cathode material for lithium-ion batteries. The raw materials used in the synthesis process are calculated in parts by mass, and their composition and content are as follows:

[0043] Lithium hydroxide 64 parts

[0044] Manganese sulfate 85 parts

[0045] Phosphoric acid 58 parts

[0046] PEG400 65 parts

[0047] 100 parts of deionized water;

[0048] Its synthetic method specifically comprises the following steps:

[0049] (1) Dissolve 58 parts of phosphoric acid in 20 parts of deionized water to make a phosphoric acid solution, add 65 parts of PEG400 under stirring and stir for 10 minutes to obtain a mixed solution of phosphoric acid / PEG400;

[0050] (2) Dissolve 64 parts of lithium hydroxide in 40 parts of deionized water to make lithium hydroxide aqueous solution, and add the obtained lithium hydroxide aqueous solution to the phosphoric acid / PEG400 mixed solution obtained in step (1) while stirring ...

Embodiment 2

[0058] A method for synthesizing nano-manganese lithium phosphate as a cathode material for lithium-ion batteries. The raw materials used in the synthesis process are calculated in parts by mass, and their composition and content are as follows:

[0059] Lithium hydroxide 64 parts

[0060] Manganese sulfate 85 parts

[0061] Phosphoric acid 58 parts

[0062] PEG400 80 parts

[0063] 100 parts of deionized water;

[0064] Its synthetic method specifically comprises the following steps:

[0065] (1) Dissolve 58 parts of phosphoric acid in 20 parts of deionized water to make a phosphoric acid solution, add 80 parts of PEG400 under stirring and stir for 10 minutes to obtain a mixed solution of phosphoric acid / PEG400;

[0066] (2) Dissolve 64 parts of lithium hydroxide in 40 parts of deionized water to make lithium hydroxide aqueous solution, and add the obtained lithium hydroxide aqueous solution to the phosphoric acid / PEG400 mixed solution obtained in step (1) while stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com