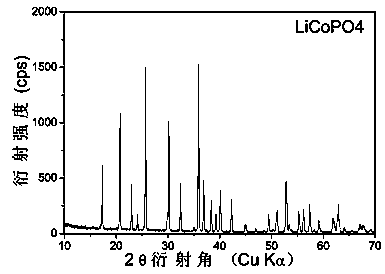

Synthetic method for cathode material lithium cobaltous phosphate used for lithium ion batteries

A lithium-ion battery, lithium cobalt phosphate technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve the problem of high energy consumption, uniformity, consistency, poor reproducibility, and large particle size. and other problems, to achieve the effect of increasing specific capacity and improving rate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Battery preparation and electrochemical performance testing methods

[0037] ① Preparation of battery positive electrode sheet

[0038] Calculate the lithium cobalt phosphate lithium ion battery cathode material, conductive carbon powder, and organic binder polyvinylidene fluoride (PVDF) according to the mass ratio, that is, the lithium ion battery cathode material cobalt lithium phosphate: conductive carbon powder: organic binder Polyvinylidene fluoride is mixed at a ratio of 92:3:5 to obtain a mixed powder. Add 10 grams of the mixed powder to 12 grams of organic solvent N-methylpyrrolidone (NMP), stir well to form a slurry, and coat Cover the surface of aluminum foil, after drying, roll it several times to obtain the positive electrode sheet of the battery;

[0039] ②, battery assembly and performance testing

[0040] The electrochemical performance of obtained lithium cobalt phosphate was evaluated using a 2016-type half-cell. The rolled positive electrode sheet o...

Embodiment 1

[0045] A method for synthesizing lithium cobalt phosphate, an anode material for lithium ion batteries, using lithium hydroxide, cobalt acetate, phosphoric acid, nitric acid, sucrose and deionized water as raw materials, the raw materials are calculated in parts by mass, and their composition and content are as follows:

[0046] Lithium hydroxide 42 parts

[0047] Cobalt acetate 249 parts

[0048] Phosphoric acid 115 parts

[0049] 15 parts nitric acid

[0050] 15 parts sucrose

[0051] 650 parts of deionized water;

[0052] Its synthetic method specifically comprises the following steps:

[0053] (1), 249 parts of cobalt acetate are dissolved in 300 parts of deionized water to make cobalt acetate aqueous solution;

[0054] 42 parts of lithium hydroxide and 15 parts of sucrose are dissolved in 250 parts of deionized water to form lithium hydroxide / sucrose mixed solution;

[0055] Add 115 parts of phosphoric acid to 100 parts of deionized water to make a phosphoric acid s...

Embodiment 2

[0063] A method for synthesizing lithium cobalt phosphate lithium ion battery anode material, that is, using lithium hydroxide, cobalt acetate, phosphoric acid, nitric acid, sucrose and deionized water as raw materials, the raw materials are calculated in parts by mass, and their composition and content are as follows :

[0064] Lithium hydroxide 38 parts

[0065] Cobalt acetate 224 parts

[0066] Phosphoric acid 105 parts

[0067] 15 parts nitric acid

[0068] 15 parts sucrose

[0069] 650 parts of deionized water;

[0070] Its synthetic method specifically comprises the following steps:

[0071] (1), 224 parts of cobalt acetate are dissolved in 300 parts of deionized water to make cobalt acetate aqueous solution;

[0072] 38 parts of lithium hydroxide and 15 parts of sucrose are dissolved in 250 parts of deionized water to form lithium hydroxide / sucrose mixed solution;

[0073] Add 105 parts of phosphoric acid to 100 parts of deionized water to make a phosphoric acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com