Preparation method of ternary layered positive electrode material for sodium ion battery

A sodium-ion battery and ternary layered technology, applied in the field of materials science, can solve the problems of complex process, environmental pollution, a large amount of waste water, etc., and achieve the effect of simple preparation process and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] Battery preparation and electrochemical performance testing methods

[0071] 1. Preparation of battery cathode sheet

[0072] The obtained sodium ion battery cathode material NaMn 1-x-y Fe x Ni y o 2 (0<x<0.5, 0<y<0.5), conductive carbon powder, and organic binder polyvinylidene fluoride (PVDF) are mixed in a ratio of 8:1:1 to obtain a mixture, and the mixed powder is added to N -Methylpyrrolidone (NMP), fully stirred to form a slurry, coated on the surface of aluminum foil, dried, and rolled several times to obtain the desired battery positive sheet.

[0073] 2. Battery assembly and performance testing

[0074] Evaluation of the obtained sodium-ion battery cathode material NaMn with a 2016-type half-cell 1-x-y Fe x Ni y o 2 (01-x-y Fe x Ni y o 2 (0<x<0.5, 0<y<0.5) mass, using glass fiber as separator, metal sodium sheet as negative electrode, assembled in a glove box as a testable battery.

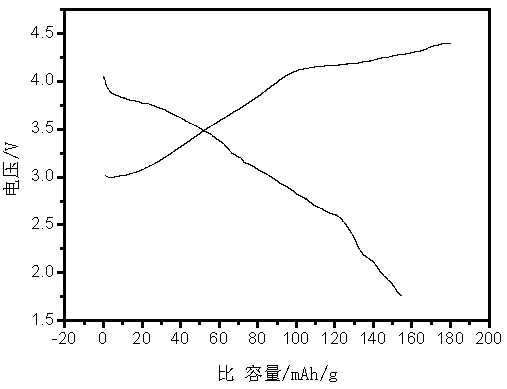

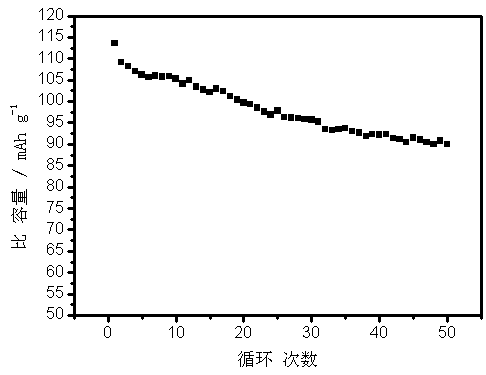

[0075] 3. Electrochemical performance test

[0076] The specific...

Embodiment 1

[0078] A preparation method of a ternary layered positive electrode material for a sodium ion battery, the raw materials used in the preparation process are calculated according to the mass fraction, and its composition and content are as follows:

[0079]

[0080] Its preparation method specifically comprises the following steps:

[0081] (1) weigh sodium carbonate by above mass ratio, manganese monoxide, iron oxide and nickel oxide raw material;

[0082] (2) Mix the weighed raw materials together, add a small amount of deionized water to make the solid content 30%, and stir evenly;

[0083] (3) adding (2) gained mixture to ball milling in the ball mill, the ball mill rotating speed is 2500r / min, after the ball milling 40min, the gained material after the ball milling;

[0084] (4) Spray the material obtained in (3), and then collect the material obtained by spraying, which is the precursor;

[0085] (5) The precursor obtained in (4) was calcined in air at 900°C for 12 h...

Embodiment 2

[0089] A preparation method of a ternary layered positive electrode material for a sodium ion battery, the raw materials used in the preparation process are calculated according to the mass fraction, and its composition and content are as follows:

[0090]

[0091] Its preparation method specifically comprises the following steps:

[0092] (1) weigh sodium carbonate by above mass ratio, manganese monoxide, iron oxide and nickel oxide raw material;

[0093] (2) Mix the weighed raw materials together, add a small amount of deionized water to make the solid content 30%, and stir evenly;

[0094] (3) adding (2) gained mixture to ball milling in the ball mill, the ball mill rotating speed is 2500r / min, after the ball milling 40min, the gained material after the ball milling;

[0095] (4) Spray the material obtained in (3), and then collect the material obtained by spraying, which is the precursor;

[0096] (5) The precursor obtained in (4) was calcined at 900°C in air for 12 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com