Lithium ion battery aqueous adhesive as well as preparation method and lithium ion battery electrode piece thereof

A technology of lithium-ion batteries and water-based binders, applied in battery electrodes, non-aqueous electrolyte battery electrodes, adhesives, etc., can solve problems such as high price, general CMC viscosity, and easy cracking of pole pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Add 80g of polyvinyl alcohol (the molar number of repeating unit M is 1.82mol) into 500g of an aqueous solution of lithium silicate with a mass fraction of 2%, stir at 40°C for 2 hours, then heat up to 60°C, and add 50g of a mass fraction of 60 % acrylamide aqueous solution reaction, heat preservation reaction for 4 hours, then lower the temperature to 50 ° C, add 4 g of ammonium persulfate aqueous solution with a mass fraction of 0.1% and 40 g of acrylic acid aqueous solution with a mass fraction of 50%, and heat preservation reaction for 5 hours to obtain a viscous liquid. It is a water-based adhesive.

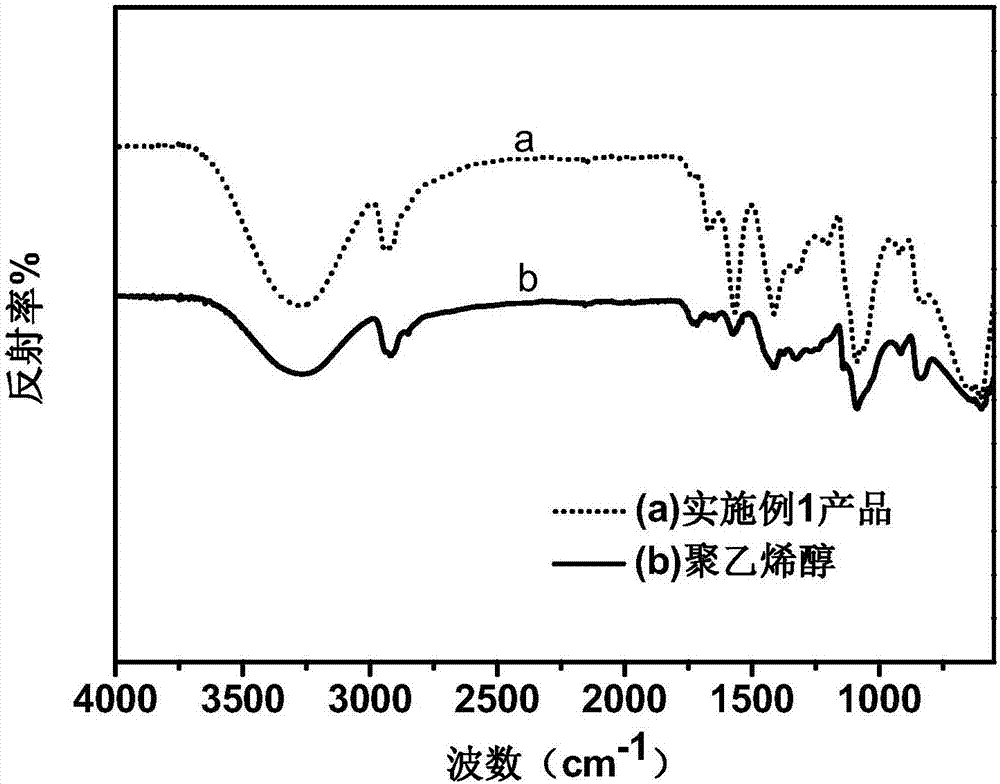

[0075] figure 1 It is the infrared comparison spectrum of the water-based binder obtained in Example 1 of the present invention and the raw material polyvinyl alcohol. Depend on figure 1 It can be seen that the product of embodiment 1 is at 1409cm -1 There is an obvious symmetrical stretching vibration peak of carboxyl salt at 1566cm -1 with 1664cm -1 There is an...

Embodiment 2

[0077] 80g of polyvinyl alcohol (the molar number of the repeating unit M is 1.82mol) was added to 500g of an aqueous solution of 5% lithium silicate by mass fraction, stirred at 50°C for 0.5 hours, then heated to 90°C, and 32.3g of 40% acrylamide aqueous solution reaction, heat preservation reaction for 0.5 hours, then lower the temperature to 30°C, add 4g of ammonium persulfate aqueous solution with a mass fraction of 0.1% and 40g of acrylic acid aqueous solution with a mass fraction of 50%, and heat preservation reaction for 5 hours to obtain a viscous liquid .

Embodiment 3

[0079] Add 80g of polyvinyl alcohol (the molar number of repeating unit M is 1.82mol) into 500g of an aqueous solution of lithium silicate with a mass fraction of 10%, stir at 30°C for 2 hours, then raise the temperature to 90°C, and add 86g with a mass fraction of 60% % acrylamide aqueous solution and 10.6g methyl oxirane to react, heat preservation reaction for 4 hours, then cool down to 80°C, add 4g mass fraction of 0.1% ammonium persulfate aqueous solution and 40g mass fraction of 50% acrylic acid aqueous solution , Insulated for 10 hours to obtain a viscous liquid, which is the water-based binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com