Air filtering non-woven fabric for air inlet filter screen of air conditioner, and preparation method of air filtering non-woven fabric

An air filtration and non-woven technology, applied in the field of air purification, can solve the problems of inapplicability, non-woven adsorption, electrostatic adsorption force attenuation, etc., to overcome the poor adsorption effect and enhance the adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

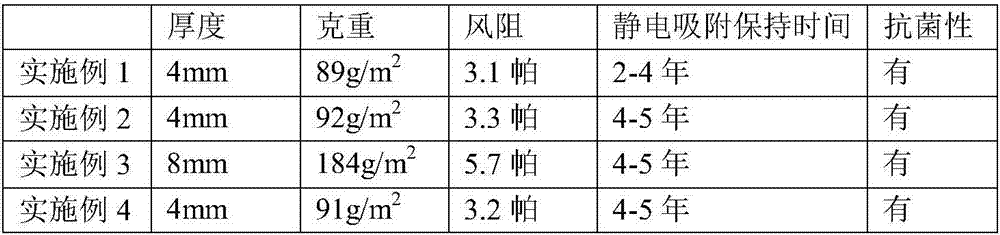

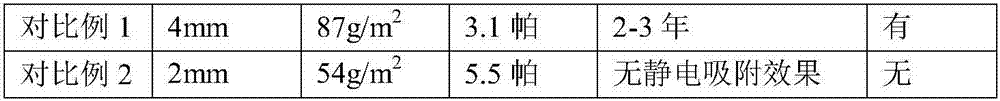

Embodiment 1

[0041] An air-filtering non-woven fabric for an air-conditioning air inlet filter, which is composed of an electrostatic adsorption layer and an antibacterial layer at intervals. The total number of single layers of the air-conditioning air-inlet filter is two layers; The adsorption layer is the air inlet surface. The wind resistance of the electrostatic adsorption layer is greater than that of the antibacterial layer.

[0042] Wherein, the electrostatic adsorption layer is polyethylene non-woven fabric containing nano-electret, and the polyethylene non-woven fabric containing nano-electret is made from the following raw materials in mass percentage:

[0043] Polyethylene 79%,

[0044] Hydrophobic cyclodextrin 2%,

[0045] Nano sepiolite 5%,

[0046] Silane coupling agent 1%,

[0047] PTFE 13%.

[0048] The antibacterial layer is polyethylene non-woven fabric compounded with polypeptide silver.

[0049] A method for preparing an air-filtering non-woven fabric for an air-co...

Embodiment 2

[0057] An air-filtering non-woven fabric for an air-conditioning air inlet filter, which is composed of an electrostatic adsorption layer and an antibacterial layer at intervals. The total number of single layers of the air-conditioning air-inlet filter is two layers; The adsorption layer is the air inlet surface. The wind resistance of the electrostatic adsorption layer is greater than that of the antibacterial layer.

[0058] Wherein, the electrostatic adsorption layer is polyethylene non-woven fabric containing nano-electret, and the polyethylene non-woven fabric containing nano-electret is made from the following raw materials in mass percentage:

[0059] Polyethylene 79%,

[0060] Hydrophobic cyclodextrin 2%,

[0061] Modified nano sepiolite 5%,

[0062] Silane coupling agent 1%,

[0063] PTFE 13%.

[0064] The nano sepiolite is a modified nano sepiolite, and the modification method is as follows: soak the nano sepiolite in an acetic acid solution with a mass concent...

Embodiment 3

[0074] An air-filtering non-woven fabric for an air-conditioning air inlet filter, which is composed of an electrostatic adsorption layer and an antibacterial layer at intervals. The total number of single layers of the air-conditioning air-inlet filter is four layers; The adsorption layer is the air inlet surface. The wind resistance of the electrostatic adsorption layer is greater than that of the antibacterial layer.

[0075] Wherein, the electrostatic adsorption layer is polyethylene non-woven fabric containing nano-electret, and the polyethylene non-woven fabric containing nano-electret is made from the following raw materials in mass percentage:

[0076] Polyethylene 74%,

[0077] Hydrophobic cyclodextrin 3%,

[0078] Nano sepiolite 7%,

[0079] Silane coupling agent 1.5%,

[0080] PTFE 14.5%.

[0081] Described nano sepiolite is modified nano sepiolite, and modification method is as follows:

[0082] Soak the nano sepiolite in an acetic acid solution with a mass c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wind resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com