A kind of multiphase composite nanostructure negative electrode material and preparation method thereof

A composite nanostructure and anode material technology, applied in structural parts, battery electrodes, electrical components, etc., can solve the problems of poor cycle stability, complex preparation process, and poor rate performance of high-capacity silicon-carbon anode materials, and achieve huge industrialization Application value, simple preparation method, effect of inhibiting volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

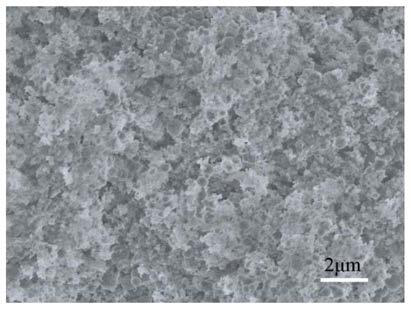

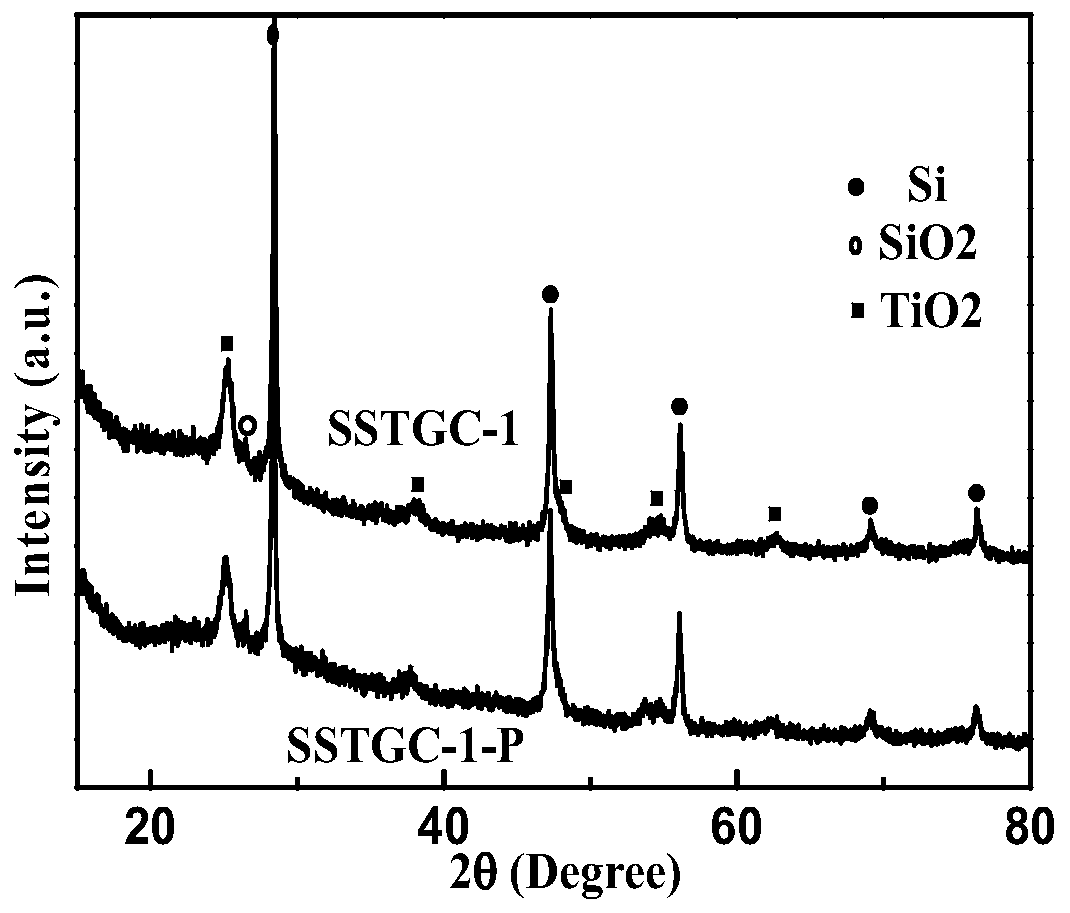

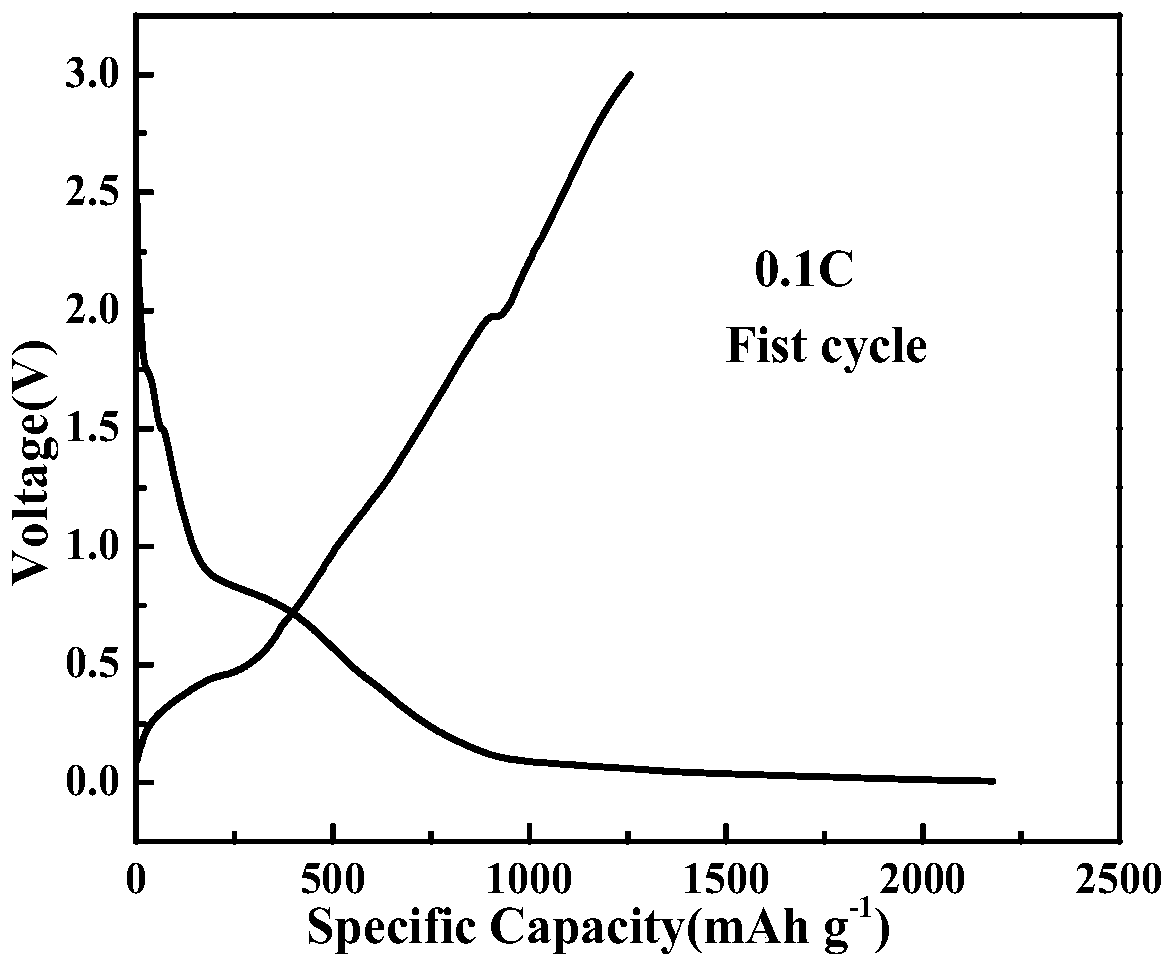

[0035] The invention is a nano-composite negative electrode material with a "concrete" structure and a preparation method thereof, belonging to a high-capacity, long-life power type and energy storage type lithium-ion battery Si / SiO 2 / TiO 2 / Graphene / C multiphase composite "concrete" nanostructure anode material and its low-cost large-scale one-time preparation method.

[0036] The technical scheme of the present invention uses silicon-containing organic substances as surfactants to modify nano-silicon particles, and uses organic titanium compounds as TiO 2 Source, using graphene oxide dispersion as dispersant and precipitant, and then using glucose, sucrose or polyvinylpyrrolidone as organic carbon source, and then preparing Si / SiO by hydrothermal reaction once 2 / TiO 2 / Graphene / C multiphase composite concrete nanostructure anode material. Its preparation steps are as follows:

[0037] (1) Weigh 1g of 50nm silicon powder and place it in 100mL of ethanol, and obtain a prel...

Embodiment 2

[0050] (1) Weigh 1g of 30nm silicon powder and place it in 100mL of ethanol, and obtain a preliminary dispersed nanosilicon ethanol suspension after 15min of ultrasonic dispersion treatment.

[0051] (2) Under the condition of constant stirring, add 1mL tetraethyl orthosilicate (TEOS) as a surfactant dropwise into the nano-silicon ethanol suspension prepared in step (1), and then obtain TEOS after 15min ultrasonic dispersion treatment Ethanol dispersion of surface-modified silicon nanoparticles.

[0052] (3) Add 0.4mL tetrabutyl titanate dropwise to the ethanol dispersion of TEOS surface-modified silicon nanoparticles obtained in step (2) under constant stirring, and after stirring at a constant speed for 1 hour, co-modified silicon nanoparticles are obtained. Nanoparticle ethanol dispersion.

[0053] (4) Take 50 mL of 1 mg / mL graphene oxide (GO) dispersion, add 50 mL of deionized water, and shake well to obtain a 0.5 mg / mL graphene oxide diluted solution.

[0054] (5) Add t...

Embodiment 3

[0062] (1) Weigh 1 g of 90 nanometer silicon powder and place it in 100 mL of ethanol, and obtain a preliminary dispersed nano silicon ethanol suspension after 15 minutes of ultrasonic dispersion treatment.

[0063] (2) Under the condition of uniform stirring, add 0.4mL tetraethyl orthosilicate (TEOS) as a surfactant dropwise into the nano-silicon ethanol suspension prepared in step (1), followed by 30min ultrasonic dispersion treatment to obtain Ethanol dispersion of TEOS surface-modified silicon nanoparticles.

[0064] (3) Add 0.2mL tetrabutyl titanate dropwise to the ethanol dispersion of TEOS surface-modified silicon nanoparticles obtained in step (2) under constant stirring, and stir at a constant speed for 30 minutes to obtain co-modified silicon nanoparticles. Nanoparticle ethanol dispersion.

[0065] (4) Take 50 mL of 1 mg / mL graphene oxide (GO) dispersion, add 200 mL of deionized water, and shake to obtain a 0.2 mg / mL graphene oxide diluted solution.

[0066] (5) Ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com