Preparation method of high-quality gamma-TiAl spherical powder

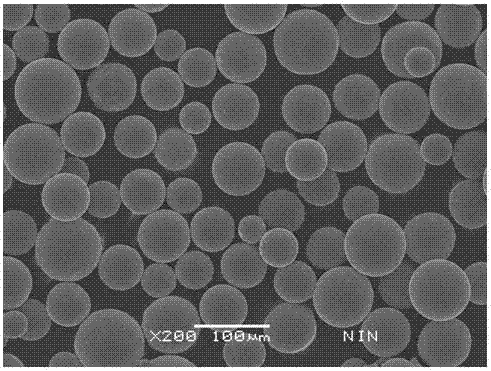

A spherical powder, high-quality technology, applied in the field of preparation of high-quality γ-TiAl spherical powder, to achieve the effect of high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of high-quality gamma-TiAl spherical powder, by mass percentage, comprises the following steps:

[0025] 1) According to the ingredients of γ-TiAl-based alloy, Ti: 48.32wt%, Al: 31.5wt%, Nb: 15.82wt%, Cr: 1.26wt%, V: 3.10%, smelting into γ-TiAl alloy rod;

[0026] 2) After forging the smelted γ-TiAl alloy rod, stress relief annealing;

[0027] 3) Finish turning the annealed γ-TiAl alloy rod. The processed high-precision alloy rod is: 85mm in diameter, 900mm in length, 0.03mm / m in circular runout, and 0.98μm in roughness;

[0028] 4) Load high-precision alloy rods into the reaction chamber, and vacuum the reaction chamber to 2*10 -3 Pa, fill the reaction chamber with helium, so that the pressure in the chamber is 0.3MPa, and the oxygen content in the atmosphere is 150ppm;

[0029] 5) The power of the plasma gun of PREP powder making equipment is 280kW. The plasma torch contains tungsten cathode and copper anode. The plasma heats the end of ...

Embodiment 2

[0037] A kind of preparation method of high-quality gamma-TiAl spherical powder, by mass percentage, comprises the following steps:

[0038] 1) According to the ingredients of γ-TiAl-based alloy, Ti: 51.93wt%, Al: 28.57wt%, Nb: 18.58wt%, W: 0.87wt%, B: 0.05wt%, smelted into γ-TiAl alloy rod ;

[0039] 2) Stress relief annealing after forging the smelted γ-TiAl alloy rod;

[0040] 3) Finish turning the annealed γ-TiAl alloy rod. The processed high-precision alloy rod is: 35mm in diameter, 150mm in length, 0.07mm in circular runout, and 2.5μm in roughness;

[0041] 4) Load alloy rods into the reaction chamber, and vacuum the reaction chamber to 9*10 -3 Pa, fill the reaction chamber with a mixture of helium and argon, so that the pressure in the chamber is 0.07MPa, and the oxygen content in the atmosphere is 350ppm;

[0042] 5) The power of the plasma gun of PREP powder making equipment is 150kW. The plasma torch contains tungsten cathode and copper anode. The plasma heats the...

Embodiment 3

[0050] A kind of preparation method of high-quality gamma-TiAl spherical powder, by mass percentage, comprises the following steps:

[0051] 1) According to the ingredients of γ-TiAl-based alloy, Al: 26.89wt%, Nb: 9.85wt%, Ti: 38.57wt%, Cr: 5.51wt%, Ta: 19.18wt%, and smelted into γ-TiAl alloy Great;

[0052] 2) Forging the smelted γ-TiAl alloy rod, followed by stress relief annealing;

[0053] 3) Finish turning the annealed γ-TiAl alloy rod. The processed high-precision alloy rod is: 66mm in diameter, 550mm in length, 0.05mm in circular runout, and 1.89μm in roughness;

[0054] 4) Load high-precision alloy rods into the reaction chamber, and vacuum the reaction chamber to 1*10 -3 Pa, fill the reaction chamber with argon, so that the pressure in the chamber is 0.75MPa, and the oxygen content in the atmosphere is 300ppm;

[0055] 5) The power of the plasma gun of the PREP powder making equipment is 250kW. The plasma torch contains tungsten cathode and copper anode. The plasma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com