N-type crystalline silicon solar battery and preparation method thereof

A solar cell and crystalline silicon technology, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effect of simple production process, improved battery efficiency, and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

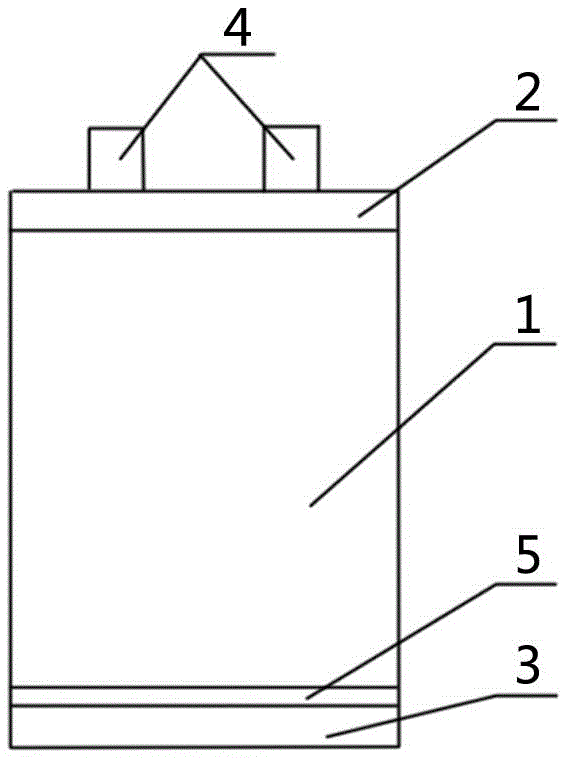

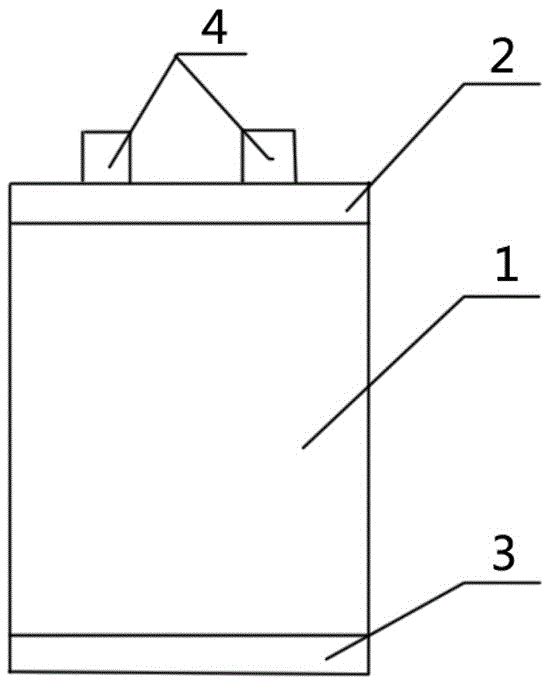

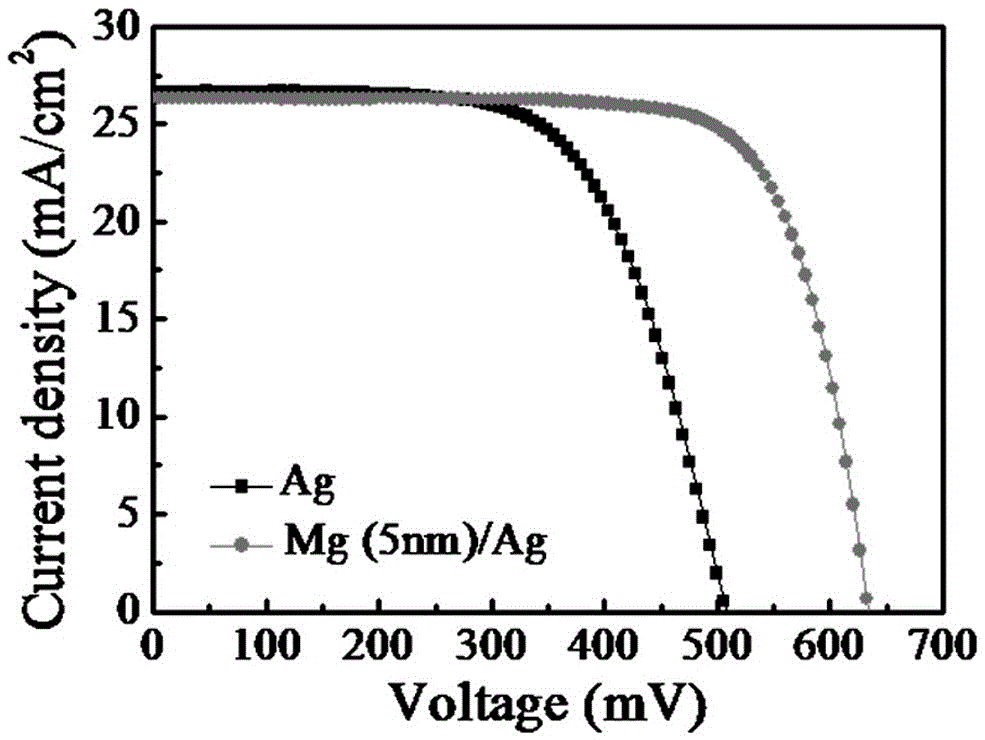

[0031] In this embodiment, the back field of the battery is hybridized with low work function metal magnesium (Mg). The battery structure in this embodiment is as figure 1 As shown: an emitter 2 is formed on the front side of the n-type crystalline silicon 1, a front electrode 4 is formed on the emitter 2, a Mg film layer 5 is formed on the back side of the n-type crystalline silicon 1, and a Mg film layer 5 is formed on the Mg film layer 5. There is a back electrode 3 . The battery in this embodiment is an organic-inorganic hybrid solar battery.

[0032] combine figure 1 , the preparation method of the battery in this embodiment is as follows:

[0033] 1) Treat n-type crystalline silicon 1 .

[0034] In this embodiment, the n-type crystalline silicon 1 is an n-type single crystal silicon wafer. First, the n-type single crystal silicon wafer was polished on both sides, and then the double-sided polished n-type single crystal silicon wafer was cleaned in a hydrofluoric aci...

Embodiment 2

[0057] In this embodiment, the battery back field is hybridized with low work function metal germanium (Ge). The battery structure in this embodiment is as Figure 5 As shown: an emitter 2 is formed on the front side of the n-type crystalline silicon 1, a front electrode 4 is formed on the emitter 2, a Ge film layer 13 is formed on the back side of the n-type crystalline silicon 1, and a Ge film layer 13 is formed on the Ge film layer 13. There is a back electrode 3 .

[0058] combine Figure 5 , the preparation method of the battery in this embodiment is as follows:

[0059] 1) Treat n-type crystalline silicon 1 .

[0060] In this embodiment, the n-type crystalline silicon 1 is an n-type single crystal silicon wafer. First, the front side of the n-type single crystal silicon wafer is polished (that is, the n-type single crystal silicon wafer is polished on one side), and then the front polished n-type single crystal silicon wafer is cleaned in a hydrofluoric acid solution...

Embodiment 3

[0081] In this embodiment, a low work function magnesium-neodymium alloy (MgNd) is used to hybridize the back field of the battery. The battery structure in this embodiment is as Figure 8 As shown: an emitter 2 is formed on the front side of the n-type crystalline silicon 1, a front electrode 4 is formed on the emitter 2, a MgNd film layer 14 is formed on the back side of the n-type crystalline silicon 1, and a MgNd film layer 14 is formed on the MgNd film layer 14 There is a back electrode 3 .

[0082] combine Figure 8 , the preparation method of the battery in this embodiment is as follows:

[0083] 1) Treat n-type crystalline silicon 1 .

[0084] In this embodiment, the n-type crystalline silicon 1 is an n-type single crystal silicon wafer. First, the double-sided texturing of the n-type monocrystalline silicon wafer was performed, and then the double-sided textured n-type monocrystalline silicon wafer was cleaned in a hydrofluoric acid solution with a concentration o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com