Processing method for intensifying enzymolysis saccharifying of lignocelluloses

The technology of lignocellulase and lignocellulose is applied in the treatment field of strengthening lignocellulosic enzymatic hydrolysis and saccharification, can solve the problems of long pretreatment time, many chemical agents, not ideal, etc. Low and small steric hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Remove floating impurities on the surface of the massive camellia oil cake, crush it through a 40-mesh sieve, and dry the sieved tea cake powder at 40°C to remove moisture; hybrid poplar sawdust is selected from a wood processing factory, remove floating impurities, and crush it through a 40-mesh sieve Sieve, and dry the sieved sawdust at 60°C to remove moisture.

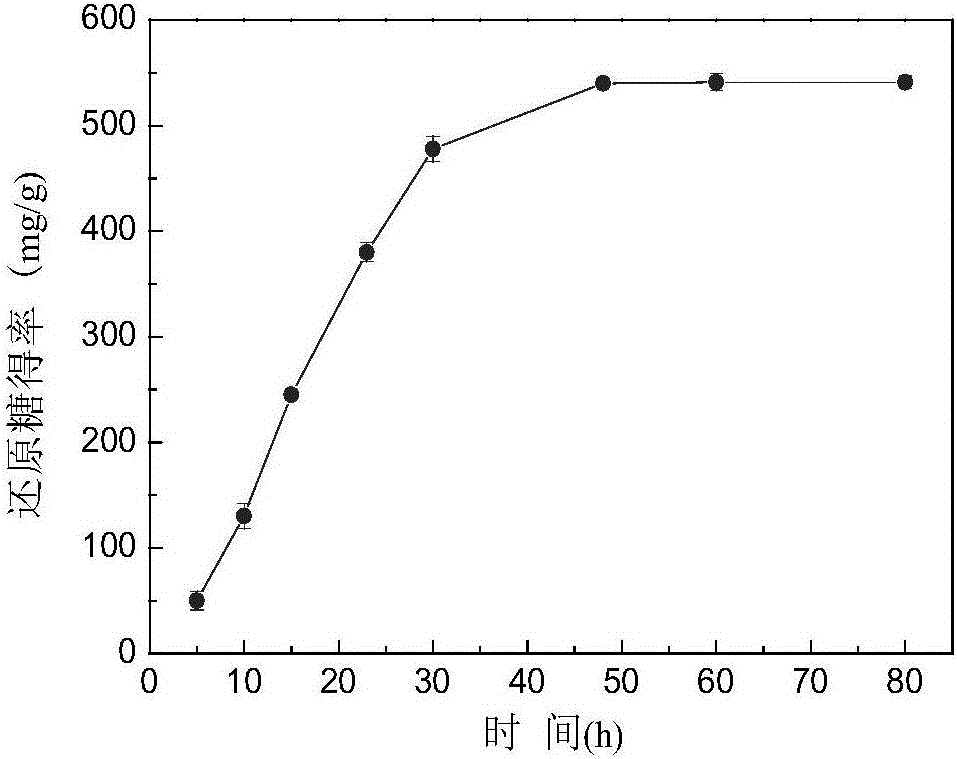

[0037] 2) Mix the dry tea cake powder in (1) with the hybrid poplar sawdust in a mass ratio of 1:20, the total mass is 1g; then fully mix the mixture with deionized water in 1L for reaction according to the mass volume ratio of 1g:5mL In the device, it was treated under the action of ultrasonic wave (108W, 20.024kHz) for 10min. Then the reactant was cooled to room temperature, the supernatant was separated by filtration, and the solid residue was dried at 100°C for 2 hours; the supernatant was removed by membrane separation technology, and the obtained substance was mixed with the solid residue for enzymat...

Embodiment 2

[0046] 1) Lumpy camellia oleifera cake removes floating impurities on the surface, crushes through a 50-mesh sieve, and dries the sieved tea cake powder at 50°C to remove moisture; hybrid poplar sawdust is selected from a wood processing factory, removes floating impurities, and crushes through a 50-mesh sieve Sieve, and dry the sieved sawdust at 60°C to remove moisture.

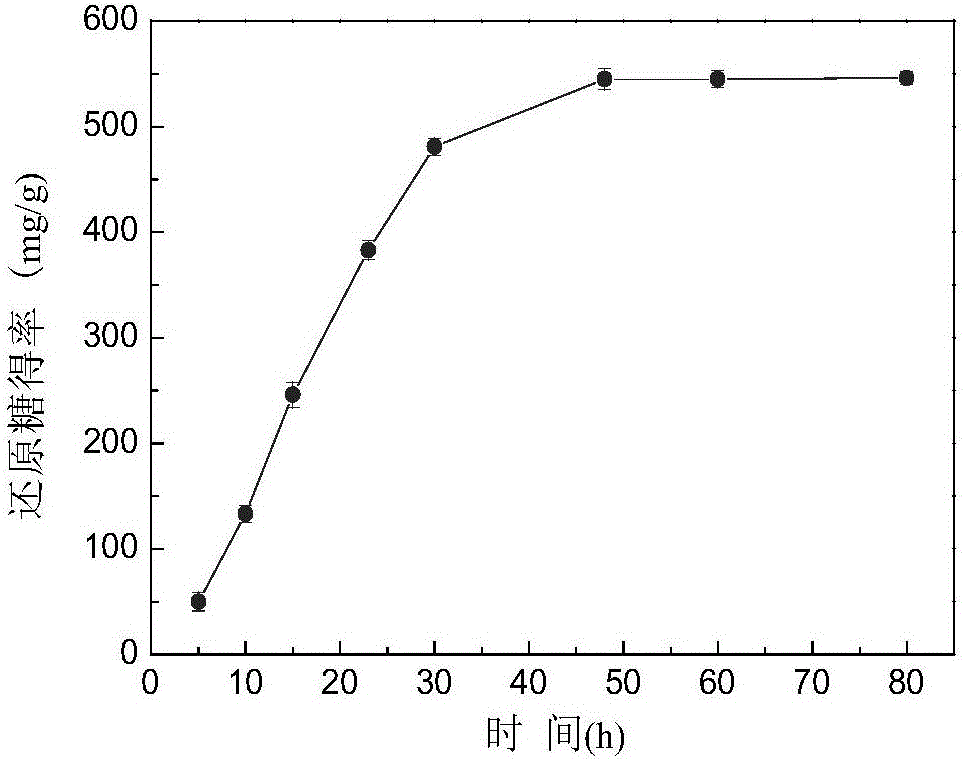

[0047] 2) Mix the dry tea cake powder in (1) with the hybrid poplar sawdust at a mass ratio of 1:18, and the total mass is 1g; then fully mix the mixture with deionized water in 1L for reaction according to the mass-volume ratio of 1g:4mL In the device, it was treated under the action of ultrasonic wave (108W, 20.024kHz) for 20min. Then the reactant was cooled to room temperature, the supernatant was separated by filtration, and the solid residue was dried at 101°C for 2.5 hours; the supernatant was removed by membrane separation technology, and the obtained substance was mixed with the solid residue for enz...

Embodiment 3

[0056] 1) Lumpy camellia oleifera cake removes floating impurities on the surface, crushes through a 60-mesh sieve, and dries the sieved tea cake powder at 55°C to remove moisture; hybrid poplar sawdust is selected from a wood processing factory, removes floating impurities, and crushes through a 60-mesh sieve Sieve, and dry the sieved sawdust at 60°C to remove moisture.

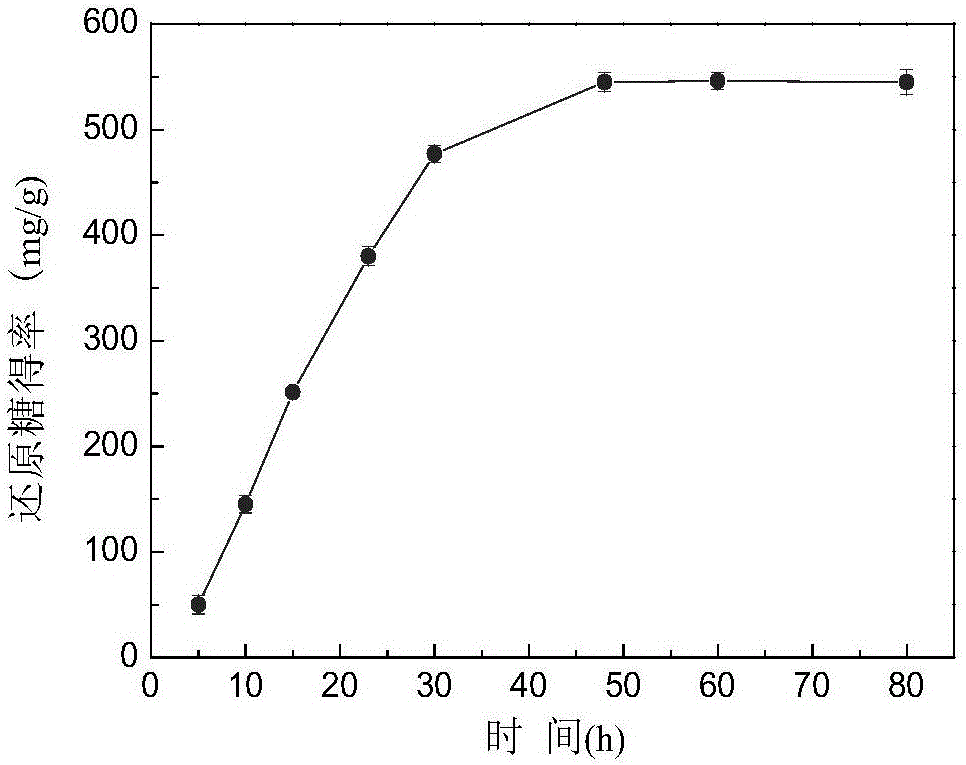

[0057] 2) Mix the dry tea cake powder in (1) with the hybrid poplar sawdust in a mass ratio of 1:16, the total mass is 1g; then fully mix the mixture with deionized water in 1L according to the mass volume ratio of 1g:2.5mL In the reactor, it was treated under the action of ultrasonic waves (108W, 20.024kHz) for 30min. Then the reactant was cooled to room temperature, the supernatant was separated by filtration, and the solid residue was dried at 103°C for 3 hours; the supernatant was removed by membrane separation technology, and the obtained substance was mixed with the solid residue for enzymatic hydrolys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com