A kind of preparation method of pmma/cnts composite material

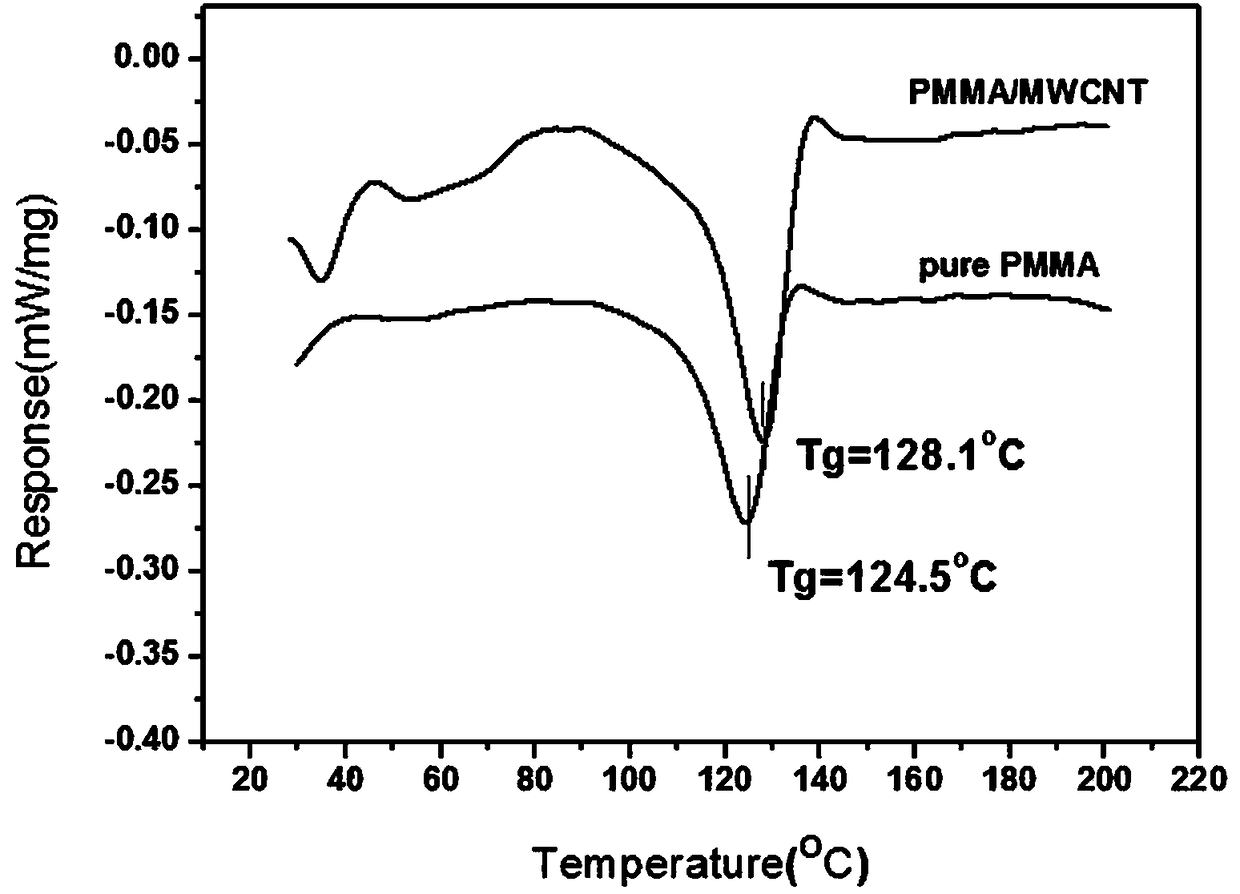

A technology of composite materials and carbon nanotubes, which is applied in the field of polymer-based nanocomposites, can solve problems such as poor dispersion, damaged intrinsic properties, and prone to violent polymerization of composite materials, achieving low polymerization reaction temperature and good dispersion , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

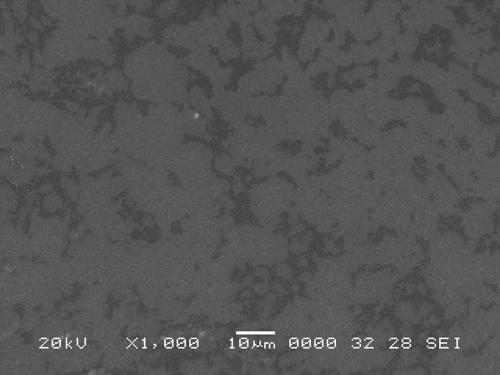

[0027] A preparation method of PMMA / multi-walled carbon nanotube composite material, specifically comprising the steps of:

[0028] (1) Weigh 20.00g of multi-walled carbon nanotubes (MWCNTs) on an electronic analytical balance, place in a beaker containing 60ml of deionized water, add 0.040g of polycarboxylate, 0.040g of organosiloxane surfactant in turn and 0.040g OP-10 alkylphenol polyoxyethylene ether, after a little stirring, disperse with ultrasonic wave for 60min;

[0029] (2) Add 0.4 g of acrylate resin emulsion obtained by copolymerization of acrylate and styrene into the material system of step (1), and continue to disperse with ultrasonic waves for 60 minutes;

[0030] (3) Place the material obtained in (2) in an oven at 100°C, evaporate and dry the deionized water to obtain a massive solid, which is ground into a powder repeatedly in a mortar after cooling to obtain a powdery surface-modified polysaccharide Walled carbon nanotubes (MWCNTs);

[0031] (4) Preparatio...

Embodiment 2

[0039] A preparation method of PMMA / single-walled carbon nanotubes (SWCNTs) composite material, specifically comprises the steps:

[0040] (1) Weigh 20.00g of single-walled carbon nanotubes on an electronic analytical balance, place them in a beaker filled with 60ml of deionized water, add 0.040g of polycarboxylate, 0.040g of organosiloxane surfactant and 0.040g of OP -10 Alkylphenol polyoxyethylene ether, after a little stirring, disperse with ultrasonic waves for 60 minutes;

[0041] (2) Add 0.4 g of acrylate resin emulsion to the material system of step (1), and continue to disperse with ultrasonic wave for 60 min;

[0042] (3) Place the material obtained in (2) in an oven at 100°C, evaporate and dry deionized water to obtain a massive solid, and after cooling, grind it repeatedly in a mortar to obtain a powdery surface-modified single walled carbon nanotubes;

[0043] (4) Preparation of PMMA / single-walled carbon nanotube composite material: Measure 10.0ml methyl methacry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com