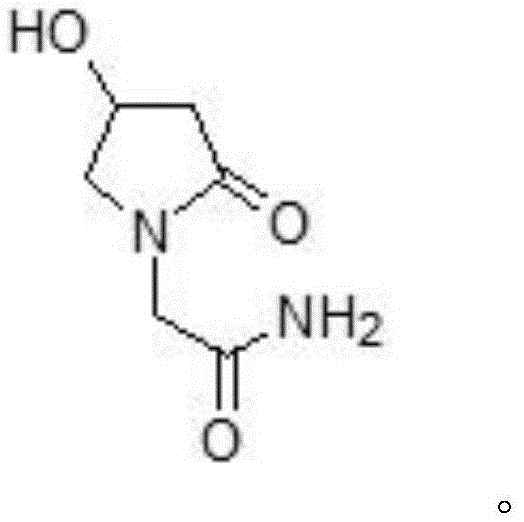

Method for preparing levo-oxiracetam oral instant film agent through hot-melting extrusion

An oral instant film and hot-melt technology, which is applied in the field of oxiracetam, can solve the problems that the disintegration time and the tensile strength are not easily controlled, the development and application of the oral instant film are restricted, and the development and production processes are complicated. Achieve the effect of improving bioavailability, avoiding elimination effects, and uniform and complete appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

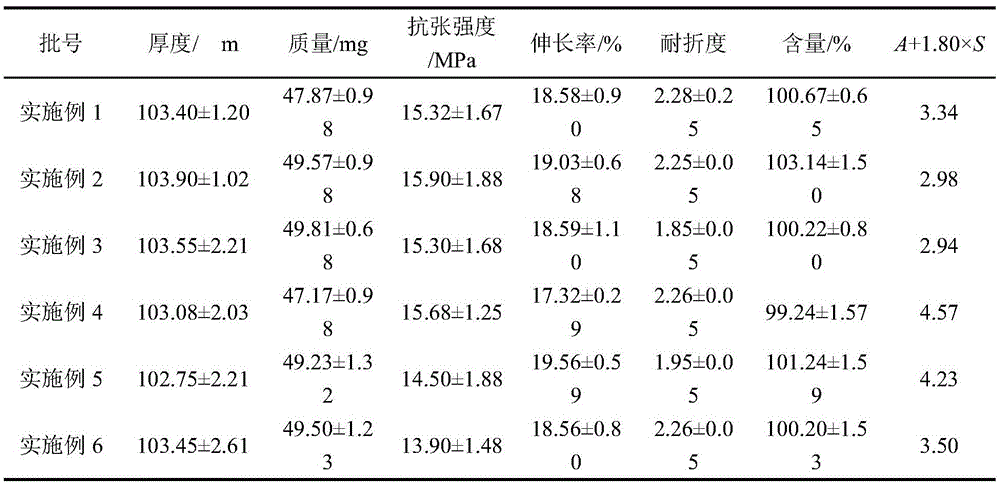

Examples

Embodiment 1

[0036] Mix 6g of levo-oxiracetam, 87g of hyaluronic acid, 4g of triethyl citrate, 2g of ascorbic acid, and 1g of fructose. After fully grinding and mixing evenly, send it to the hot-melt zone through the feed zone of the hot-melt laminator , heat-melted at 80-85°C, the molten mixture is continuously output through the metering area, poured into the mold, and forms a film after cooling.

Embodiment 2

[0038] Mix 7g of levoxiracetam, 85g of hyaluronic acid, 5g of triethyl citrate, 2g of citric acid, and 1g of aspartame. After fully grinding and mixing evenly, send it through the feeding area of the hot-melt laminating machine. Go to the hot-melt zone, heat-melt at 85-90°C, and the molten mixture is continuously output through the metering zone, poured into the mold, and forms a film after cooling.

Embodiment 3

[0040] Mix 8g of levoxiracetam, 86g of chitosan, 3g of glycerin, 2g of saliva stimulating agent, and 1g of xylitol. After fully grinding and mixing evenly, send it to the hot-melt zone through the feeding zone of the hot-melt laminator. Melting at 85-90°C, the molten mixture is continuously output through the metering area, poured into the mold, and forms a film after cooling.

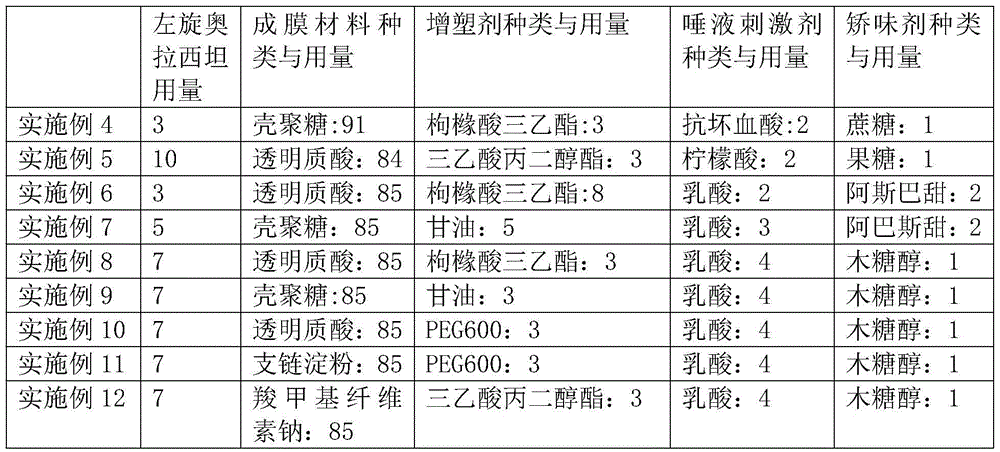

[0041] With reference to embodiment 1-3, prepare following embodiment: (consumption is weight g in the following table)

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com