Production method of second generation high temperature superconducting band metal toughness template

A high-temperature superconducting tape and metal technology, which is used in equipment for manufacturing conductive/semiconducting layers, cable/conductor manufacturing, electrical components, etc. Low, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

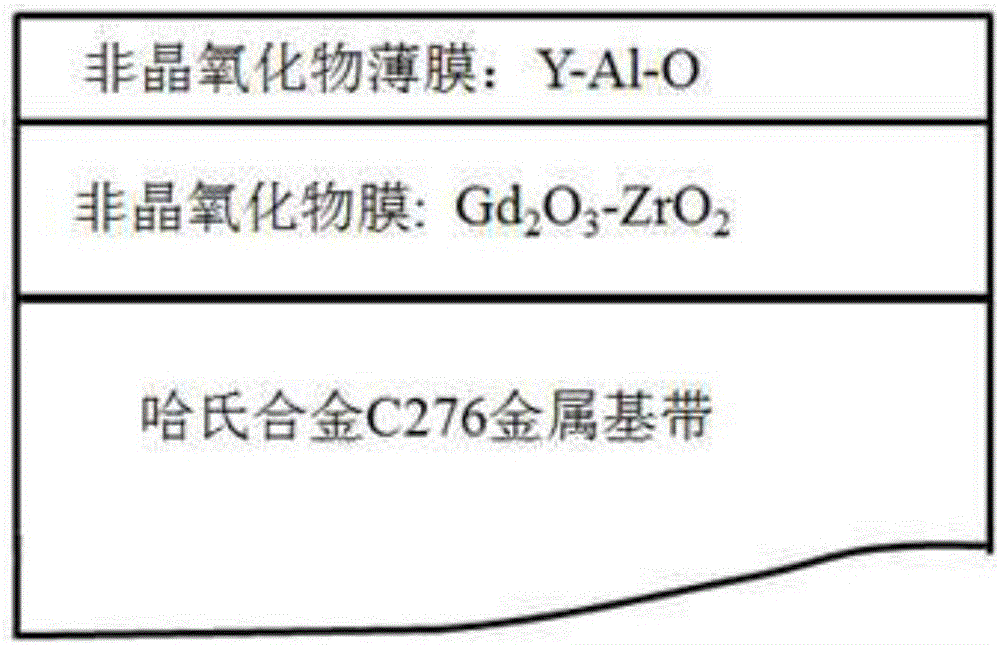

[0041] This embodiment relates to a method for preparing a second-generation high-temperature superconducting strip metal toughness template. The structure diagram of the second-generation high-temperature superconducting strip metal toughness template is as follows figure 1 shown. Described preparation method comprises the steps:

[0042] 1) The rolling process of the alloy base strip: the Hastelloy C276 base material is cold-rolled in a single pass with a reduction rate of 0.1%. The working rolls of the rolling mill used are mirror polished with a roughness of 20 nm. The thickness of the base tape after production is 0.2mm;

[0043] 2) Using chemical solution deposition technology to grow an amorphous oxide film on the Hastelloy base tape obtained in step 1; specifically: coating the precursor solution that can obtain the amorphous oxide film on the surface of the base tape, and performing heat treatment; The composition of the crystal oxide film is Gd 2 o 3 -ZrO 2 The ...

Embodiment 2

[0046] This embodiment relates to a method for preparing a second-generation high-temperature superconducting strip metal toughness template. The structure diagram of the second-generation high-temperature superconducting strip metal toughness template is as follows image 3 shown. Described preparation method comprises the steps:

[0047] 1) The rolling process of the alloy base strip: the stainless steel substrate is cold-rolled in a single pass with a reduction rate of 0.1%. The working rolls of the rolling mill used are mirror polished with a roughness of 10 nanometers. 0.1mm thick;

[0048] 2) Using chemical solution deposition technology to grow a crystalline oxide film on the Hastelloy baseband obtained in step 1; specifically: coating the precursor solution that can obtain the crystalline oxide film on the surface of the baseband, and performing heat treatment; The composition of the oxide film is La 2 o 3 -ZrO 2 -La 2 Zr 2 o 7 The mixture, the number of cycles...

Embodiment 3

[0051] This embodiment relates to a method for preparing a second-generation high-temperature superconducting strip metal toughness template. The structure diagram of the second-generation high-temperature superconducting strip metal toughness template is as follows Figure 5 shown. Described preparation method comprises the steps:

[0052] 1) The rolling process of the alloy base strip: the Hastelloy C276 base material is cold-rolled in a single pass with a reduction rate of 0.1%. The working rolls of the rolling mill used are mirror polished with a roughness of 5 nanometers. The thickness of the base tape after production is 0.05 mm;

[0053] 2) Using chemical solution deposition technology to grow a crystalline oxide film on the Hastelloy baseband obtained in step 1; specifically: coating the precursor solution that can obtain the crystalline oxide film on the surface of the baseband, and performing heat treatment; The composition of the film is YSZ, the number of cycles ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com