A brake pad for a disc brake

A technology of disc brakes and brake pads, which is applied in the field of brake pads, can solve the problems of high specific gravity of brake pads, high braking noise, and worn counterparts, and achieve good braking performance, high braking safety factor, and isolation from deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

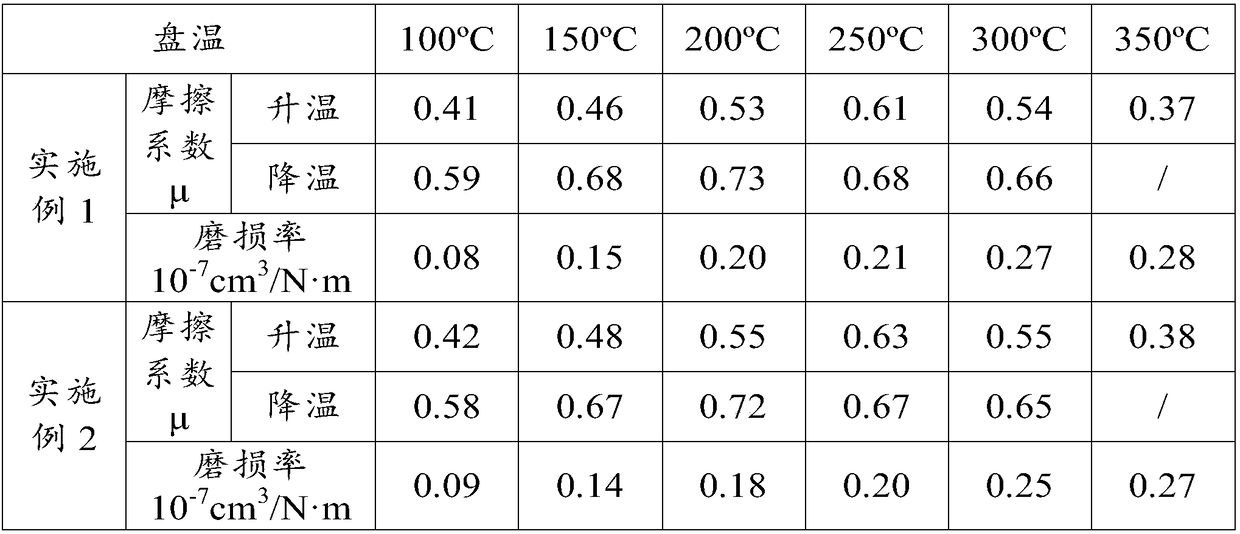

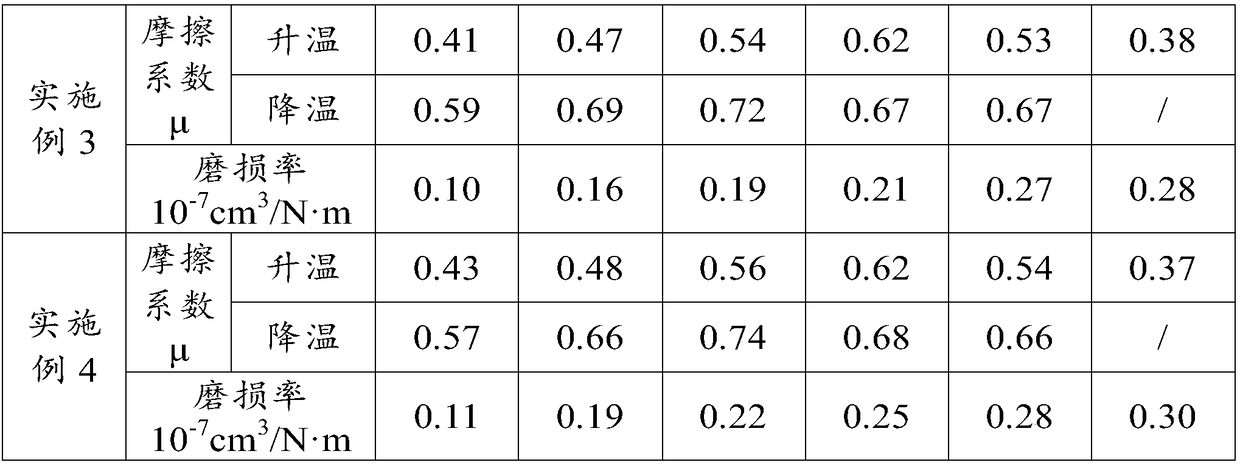

Embodiment 1

[0031] A brake pad for a disc brake, which is composed of a back plate, a heat insulating layer and a friction material, the back plate is made of stainless steel; the heat insulating layer is prepared from the following raw materials in mass percentage: foamed polyurethane 50%, polyamide Imine 25%, glass wool 11%, high silica cotton 10%, aluminum polyester 4%; the friction material is prepared from the following raw materials in mass percentage: thermosetting phenolic resin 35%, thermosetting epoxy resin 40%, chopped carbon fiber 12%, aramid fiber 6%, kaolin 2%, graphite 2%, molybdenum disulfide 1%, sodium polyacrylate 1%, polytetrafluoroethylene 1%. Wherein, the mass percent content of the chromium element in the stainless steel material is 1%.

[0032] Wherein, the preparation method of heat insulation layer comprises the following steps:

[0033] Step A, preparation of heat insulation layer substrate: Combine foamed polyurethane, polyimide, glass wool, and high silica woo...

Embodiment 2

[0041] A brake pad for a disc brake, consisting of a back plate, a heat insulating layer and a friction material, the back plate is made of stainless steel; the heat insulating layer is prepared from the following raw materials in mass percentage: foam polyurethane 65%, polyamide 15% imine, 13% glass wool, 5% high silica cotton, 2% aluminum polyester; the friction material is prepared from the following raw materials in mass percentage: 45% thermosetting phenolic resin, 45% thermosetting epoxy resin 30%, chopped carbon fiber 11%, aramid fiber 5%, kaolin 2%, graphite 2%, molybdenum disulfide 2%, sodium polyacrylate 1%, polytetrafluoroethylene 2%. Wherein, the mass percent content of chromium element in the stainless steel material is 2%.

[0042] Wherein, the preparation method of heat insulation layer comprises the following steps:

[0043] Step A, preparation of heat insulation layer substrate: Combine foamed polyurethane, polyimide, glass wool, and high silica wool in seque...

Embodiment 3

[0051] A brake pad for a disc brake, which consists of a back plate, a heat insulating layer and a friction material, the back plate is made of stainless steel; the heat insulating layer is prepared from the following raw materials in mass percentage: foam polyurethane 57%, polyamide 20% imine, 12% glass wool, 8% high silica cotton, 3% aluminum polyester; the friction material is prepared from the following raw materials in mass percentage: 42% thermosetting phenolic resin, 42% thermosetting epoxy resin 37%, chopped carbon fiber 8%, aramid fiber 6%, kaolin 1.5%, graphite 1.5%, molybdenum disulfide 1.7%, sodium polyacrylate 0.8%, polytetrafluoroethylene 1.5%. Wherein, the mass percent content of chromium element in the stainless steel material is 1.5%.

[0052] Wherein, the preparation method of heat insulation layer comprises the following steps:

[0053] Step A, preparation of heat insulation layer substrate: Combine foamed polyurethane, polyimide, glass wool, and high silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com