Sand casting die assembly

A molding device and sand foundry technology, which is applied to casting molding equipment, molding machines, manufacturing tools, etc., can solve the problems of difficult mold replacement, insufficient firmness of application, and complicated clamping of sand mold boxes, and achieve simple and firm clamping, Effects that increase the scope of application and facilitate movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

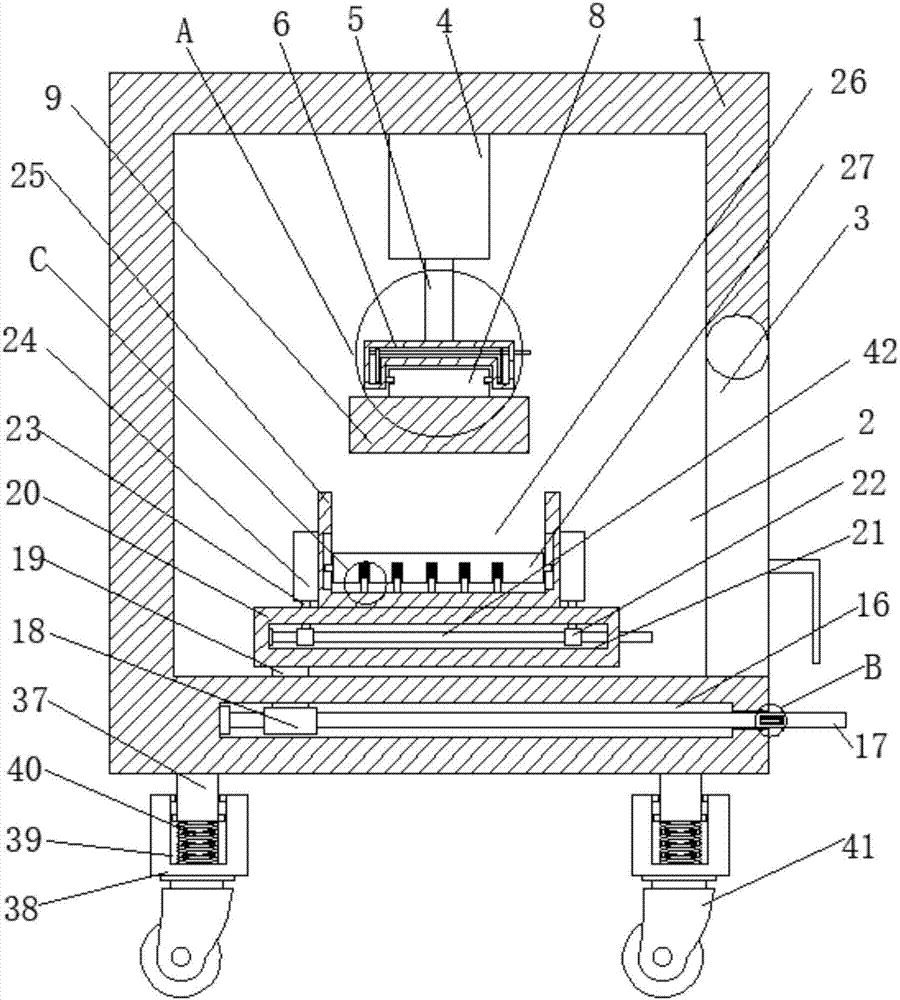

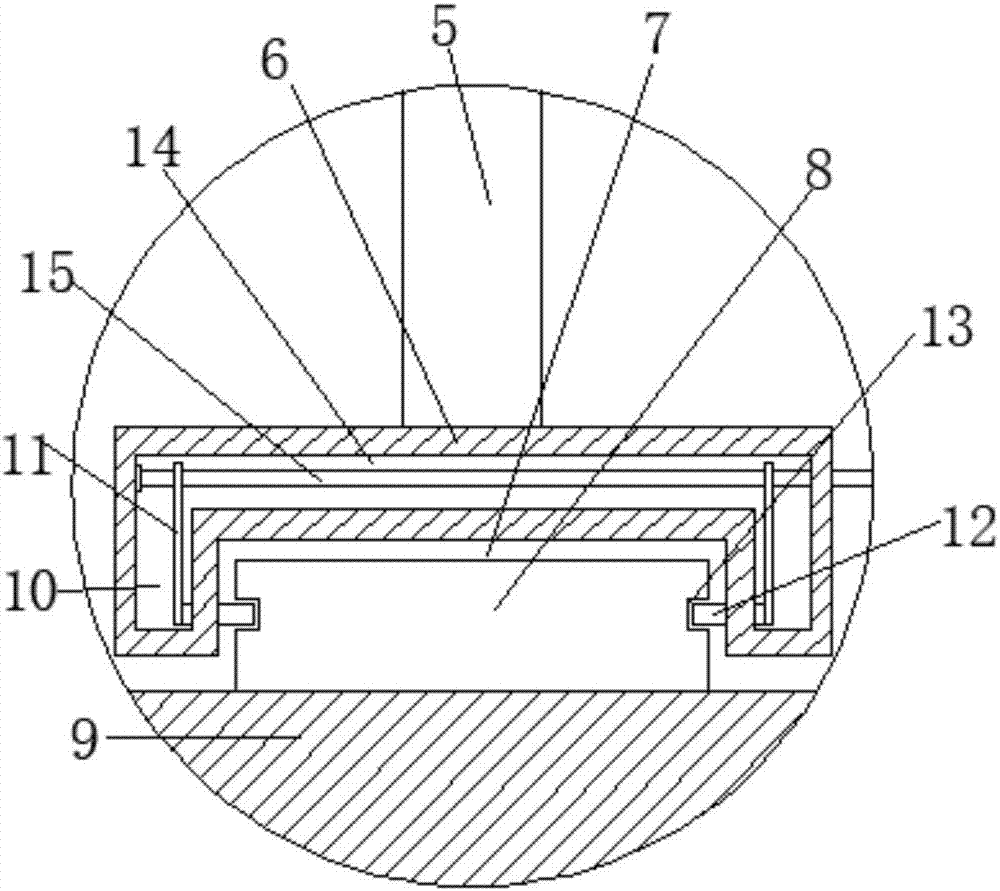

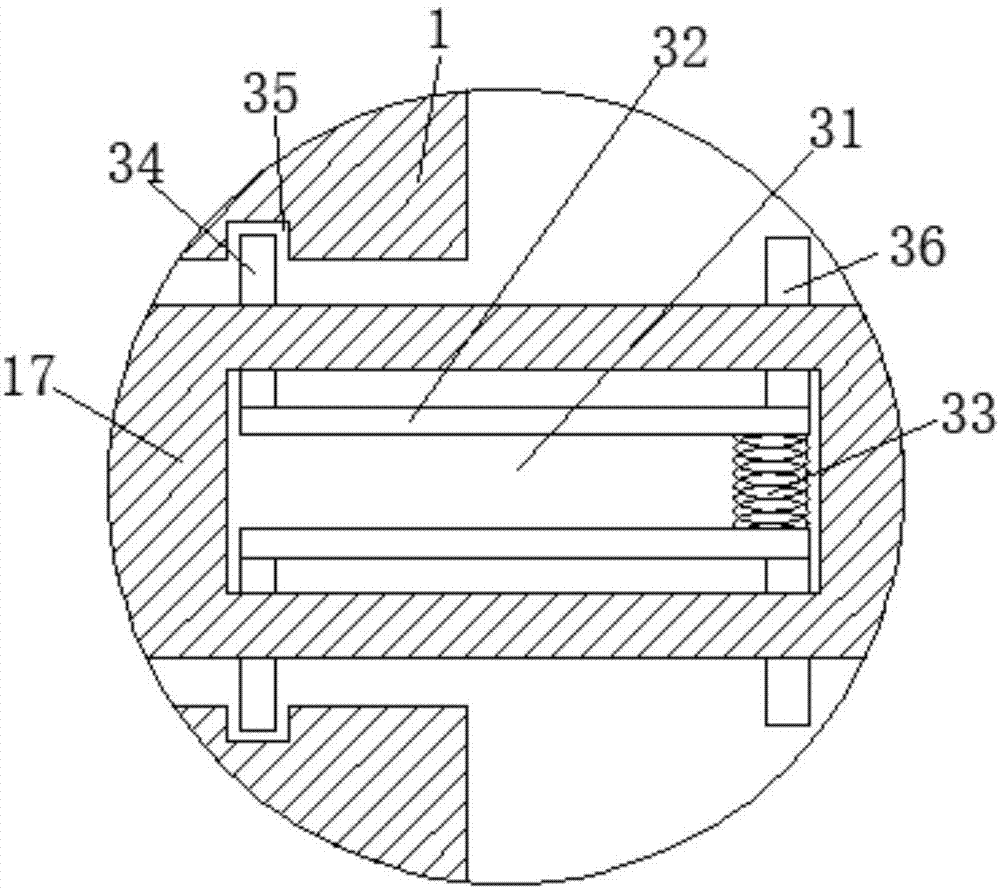

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0018] refer to Figure 1-4 , a sand foundry casting die device, comprising a housing 1, the housing 1 is hollow, the lower end of the housing 1 is also provided with a support column 37, the lower end of the support column 37 is also provided with a base 38, and the base 38 is also provided with A groove 39 with an upward opening, and the bottom of the groove 39 is connected to the support column 37 through the third spring 40. When the device is running, the vibration generated by the work is greatly weakened by the third spring 33 and then transmitted to the ground, which effectively weakens the vibration of the device. The noise pollution caused by vibration hitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com