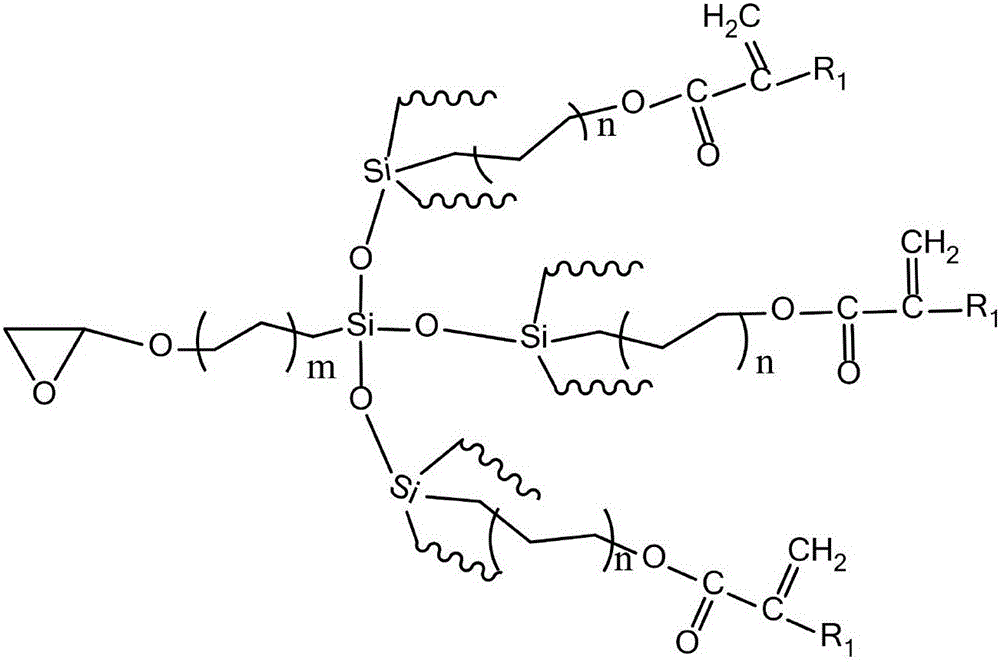

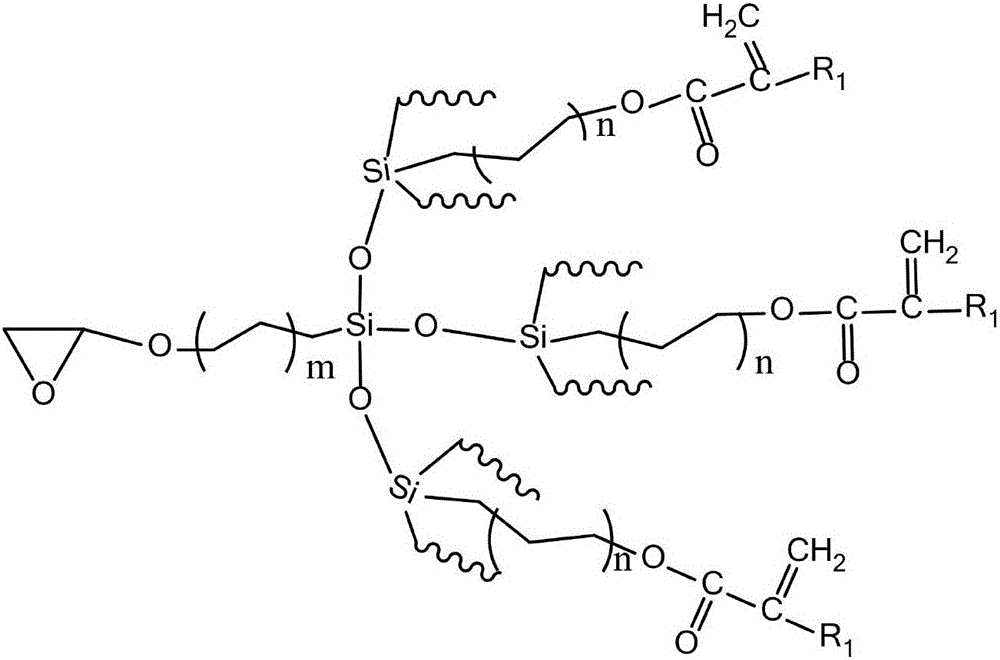

Epoxy based silicon tackifier and organosilicon conductive insulating gel prepared from same

An epoxy-based organosilicon, thermally conductive and insulating technology, applied in the direction of adhesives, etc., can solve the problems of affecting the light output performance of heat-resistant devices, poor mechanical properties of thermally conductive insulating adhesives, poor bonding performance, etc., to solve the problem of yellowing and blackening, excellent bonding performance, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Add 4.924g (20mmol) of 3-(methacryloyloxy)propyltrimethoxysilane and 20ml solvent DMF into a three-necked flask, and add 4.728g (20mol) of γ-glycidyl etheroxypropyltrimethoxysilane After mixing with 5ml of DMF, drop it into a three-neck flask with a constant pressure dropping funnel at 40°C, and drop in diluted 0.3g of HCl at the same time. After the dropwise addition was completed, the temperature was raised to 60° C., and the reaction was carried out for 12 hours. Wash until neutral, dry for 12 hours to get the prepolymer epoxy-based silicone tackifier, recorded as 2K-1.

[0028] 2. Mix 1.2g of tackifier 2K-1 with 1.5g of vinyl silicone oil (vinyl content = 0.6%), 2.5g of hydrogen-containing silicone oil and 1.0g of 0.5umAlN in a beaker, then add 0.06g of The Karstedt catalyst with a Pt content of 3000ppm is placed in a vacuum drying oven at room temperature for 30 minutes, poured into a polytetrafluoroethylene mold, pre-cured at 90°C for 1 hour, and then heated t...

Embodiment 2

[0031] 1. Add 4.924g (20mmol) of 3-(methacryloyloxy)propyltrimethoxysilane and 20ml of solvent DMF into a three-necked flask, and add 5.568g (20mol) of γ-(2,3-glycidoxy ) Propyltriethoxysilane was mixed with 5ml of DMF and added dropwise into a three-neck flask with a constant pressure dropping funnel at 40°C, and at the same time, 0.3g of diluted HCl was added dropwise. After the dropwise addition was completed, the temperature was raised to 60° C., and the reaction was carried out for 12 hours. Wash until neutral and dry for 14 hours to obtain the prepolymer as epoxy-based silicone tackifier, marked as 3K-1.

[0032] 2. Mix 1.2g of tackifier 3K-1 with 1.5g of vinyl silicone oil (vinyl content = 0.6%), 2.5g of hydrogen-containing silicone oil and 1.0g of 0.5μm AlN in a beaker, then add 0.06g of The Karstedt catalyst with a Pt content of 3000ppm is placed in a vacuum drying oven at room temperature for 30 minutes, poured into a polytetrafluoroethylene mold, pre-cured at 90°C ...

Embodiment 3

[0035] 1. Add 5.764g (20mmol) of 3-(methacryloyloxy)propyltriethoxysilane and 20ml of solvent DMF into a three-necked flask, and add 5.568g (20mol) of γ-(2,3-glycidyloxypropoxy Base) propyltriethoxysilane was mixed with 5ml of DMF and added dropwise into a three-neck flask with a constant pressure dropping funnel at 40°C, and at the same time, 0.3g of diluted HCl was added dropwise. After the dropwise addition was completed, the temperature was raised to 60° C., and the reaction was carried out for 12 hours. Wash until neutral and dry for 16 hours to obtain the prepolymer as epoxy-based silicone tackifier, marked as 4K-1.

[0036] 2. Mix 1.2g of tackifier 4K-1 with 1.5g of vinyl silicone oil (vinyl content = 0.6%), 2.5g of hydrogen-containing silicone oil and 1.0g of 0.5umAlN in a beaker, then add 0.06g of The Karstedt catalyst with a Pt content of 3000ppm is placed in a vacuum drying oven at room temperature for 30 minutes, poured into a polytetrafluoroethylene mold, pre-cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com